AC PUMP CHECK

1. Fill the basin/pit with water. The pump will start when the

water level has reached the float switch-on level.

2. The pump will stop when the water level has reached the

switch-off level.

3. Verify the switch is operating without any obstruction from

the pump, piping and basin.

4. Fill the basin/pit with water again. While the system is

draining the basin/pit, verify the discharge pipe is carrying

the water to a point at least 3 ft. away from the foundation.

If the discharge line is exposed to freezing temperatures,

the pipe must be positioned in a downward slope away

from the foundation so any remaining water will drain away

and not freeze.

CONTROL BOX INSTALLATION

1. Place battery in box, attach red cable to positive battery

post and black cable to negative battery post.

If cables are reversed, damage to the control box or

battery will result, and void warranty.

MISE EN GARDE

Si les câbles sont inversés, la boîte de

contrôle ou la batterie pourrait être endommagée et la garantie annulée.

2. Plug the float pump system and transformer into the

appropriate connectors. The connections are all unique

and cannot be interchanged.

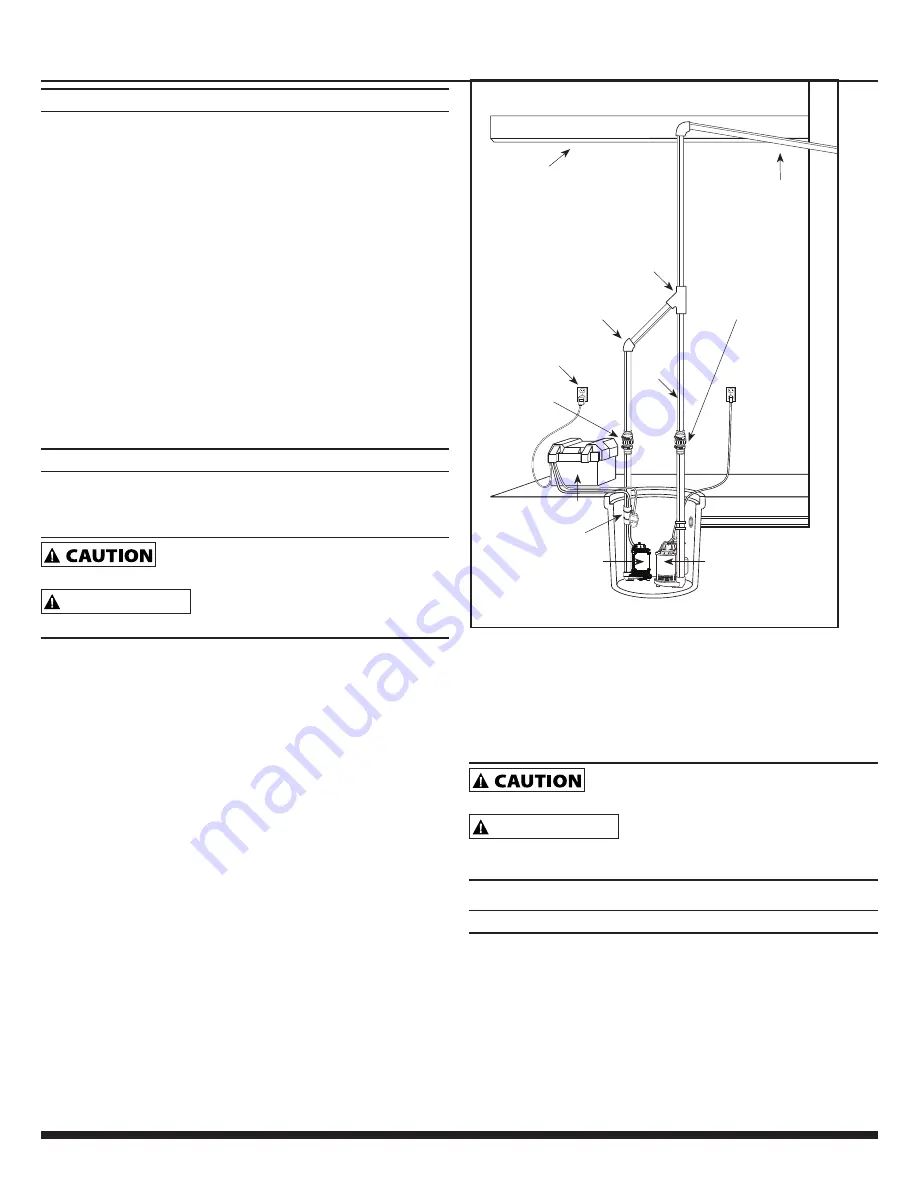

FLOOR JOIST

RIGID

PVC

PIPE

TRANSFORMER

REQUIRED

CHECK VALVE

(SEE STEP 3 & 7)

BATTERY BOX

PRIMARY AC PUMP

BACKUP DC PUMP

SLOPE

PIPE

DOWN

REQUIRED

CHECK VALVE

(SEE STEP 3)

Figure 2 - Method 2

"Y"

CONNECTOR

45º elbow

FLOAT SWITCH

3. Put lid on box, and place the battery within six feet of the

sump and a 115 VAC separately fused outlet. The

outlet must be protected by a ground fault circuit

interrupter (GFCI) The area must also be clean, dry and

well ventilated.

Do not allow battery box to get wet, or expose it to

moisture. Electronics will be damaged and void warranty.

MISE EN GARDE

Ne pas laisser le coffre de la batterie

être mouillé ou exposé à l’humidité. Les appareils électroniques seront

endommagés et la garantie sera annulée.

BACK UP PUMP CHECK

1. Test system operation by filling the sump with water

while the main pump is unplugged. If the pump operates

properly, plug the transformer into the GFCI protected

outlet to begin charging the battery.

2. Protect electrical cord from sharp objects, hot surfaces,

oil and chemicals. Avoid kinking the cord.

3. Secure power supply cord to discharge pipe using cable or

zip ties to prevent possible switch entanglement.

6

www.waynepumps.com

Operating Instructions and Parts Manual