25

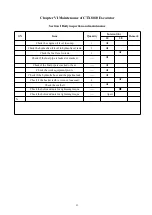

Technical maintenance

A Grease

Parts

Quantity

Interval (h)

10

50

100

250

500

1000

2000

1. Lubrication

of work

equipment

pins

Pivot at base of boom

Pivot at base of boom

cylinder

Pivots of bucket and

connecting rod

10

★

Others:

6

★

2. Lubrication of slewing bearing

2

★

3. Lubrication of external meshing

gear of slewing bearing

1

★

Note: it is recommended to use the lithium grease.

★

Maintenance interval under normal conditions

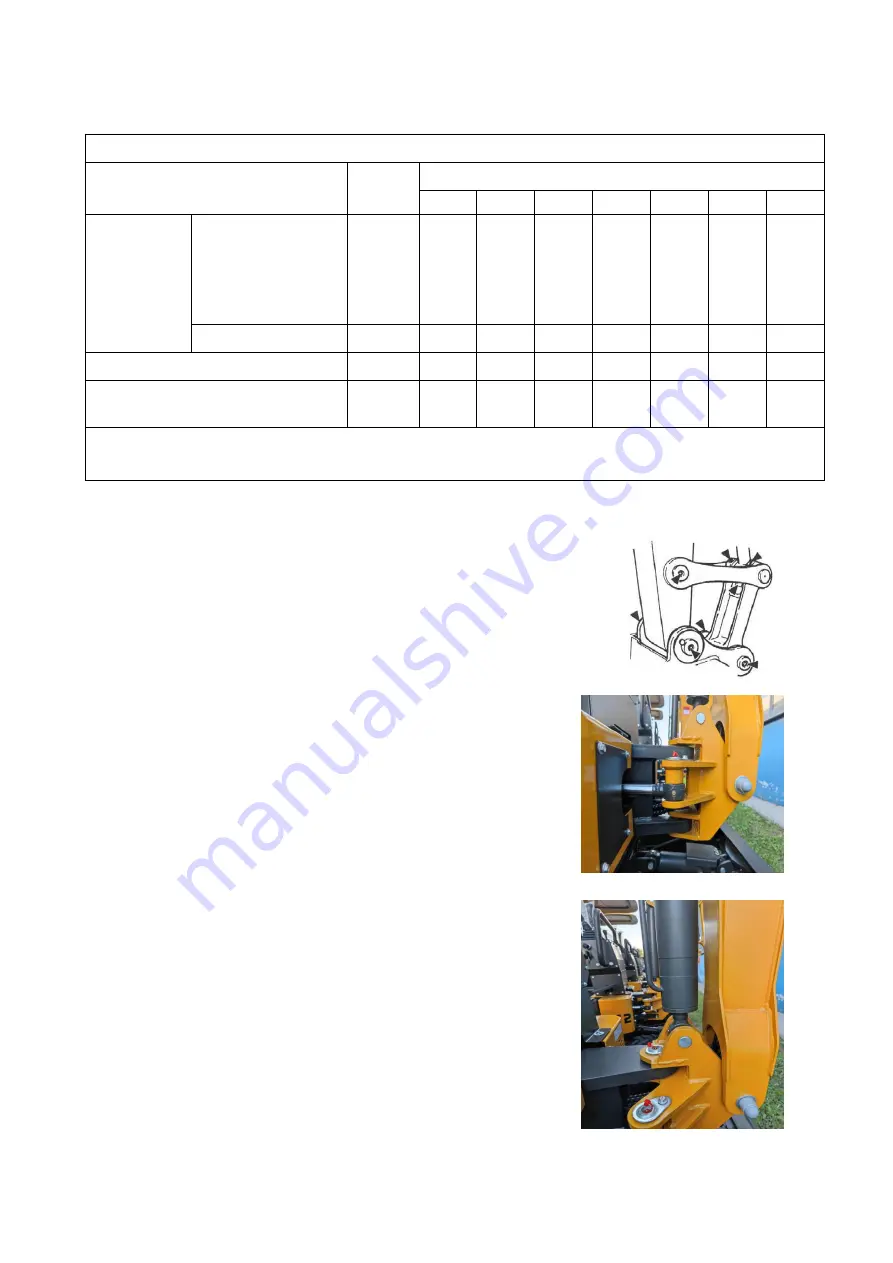

1. Maintenance and lubrication of work equipment pivots

●

Pivot between bucket and connecting rod

●

Pivot at base of boom

●

Pivot at base of boom cylinder

Summary of Contents for CTX8010

Page 1: ...1 CTX8010 MINI EXCAVATOR OPERATION PARTS MANUAL ...

Page 4: ...4 Quick hitch Narrow bucket Log grab Mechanical thumb Auger Ripper Rake ...

Page 5: ...5 Section II Main performance parameters ...

Page 13: ...12 Main pump ...

Page 15: ...14 Section IV Schematics of main valve ...

Page 16: ...15 Section V Electrical system diagram ...

Page 33: ...31 22 Lower the bucket onto the ground 23 Turn off the engine Unplug the ignitionkey ...

Page 52: ...48 ...