3

Chapter I Usage Features and Performance Parameters of CTX8010

Excavator

Section I Usage and features

CTX8010 Excavator

are provided with excavating, crushing, ditch cleaning, drilling and bulldozing, with their

attachments quick hitched and thus its utilization up greatly. In addition, they are easy to operate and transport and

flexible to work at narrow site.

CTX8010 Excavator, hydraulic type with single bucket

This type of excavators are mainly applied to: farming, landscaping, ditching and fertilization in garden, vegetable

greenhouse, agricultural transformation, indoor demolition, small earthwork, civil engineering, road recovery,

basement and indoor construction, concrete breaking, burying of cable, laying of water supply line, garden

cultivation, desilting and others.

The excavator are equipped with Changchai diesel engines, domestic main pumps and rotary motors, traveling

motor, featuring comprehensive guarantee, durability and flexibility.

Excavators are able to equipped with multiple work equipments, such as quick hitch, log grab, ripper, leveling

bucket, auger and narrow bucket, as well as optional roof, radiator and others, so as to meet your needing.

Summary of Contents for CTX8010

Page 1: ...1 CTX8010 MINI EXCAVATOR OPERATION PARTS MANUAL ...

Page 4: ...4 Quick hitch Narrow bucket Log grab Mechanical thumb Auger Ripper Rake ...

Page 5: ...5 Section II Main performance parameters ...

Page 13: ...12 Main pump ...

Page 15: ...14 Section IV Schematics of main valve ...

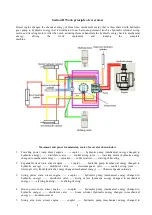

Page 16: ...15 Section V Electrical system diagram ...

Page 33: ...31 22 Lower the bucket onto the ground 23 Turn off the engine Unplug the ignitionkey ...

Page 52: ...48 ...