32

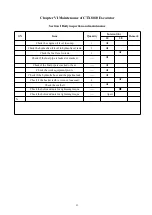

24. Check the hydraulic oil level in hydraulic oil tank and add it if needed. .

V. Inspection of hose and pipeline

--- Each day

---every 250 h

Caution:

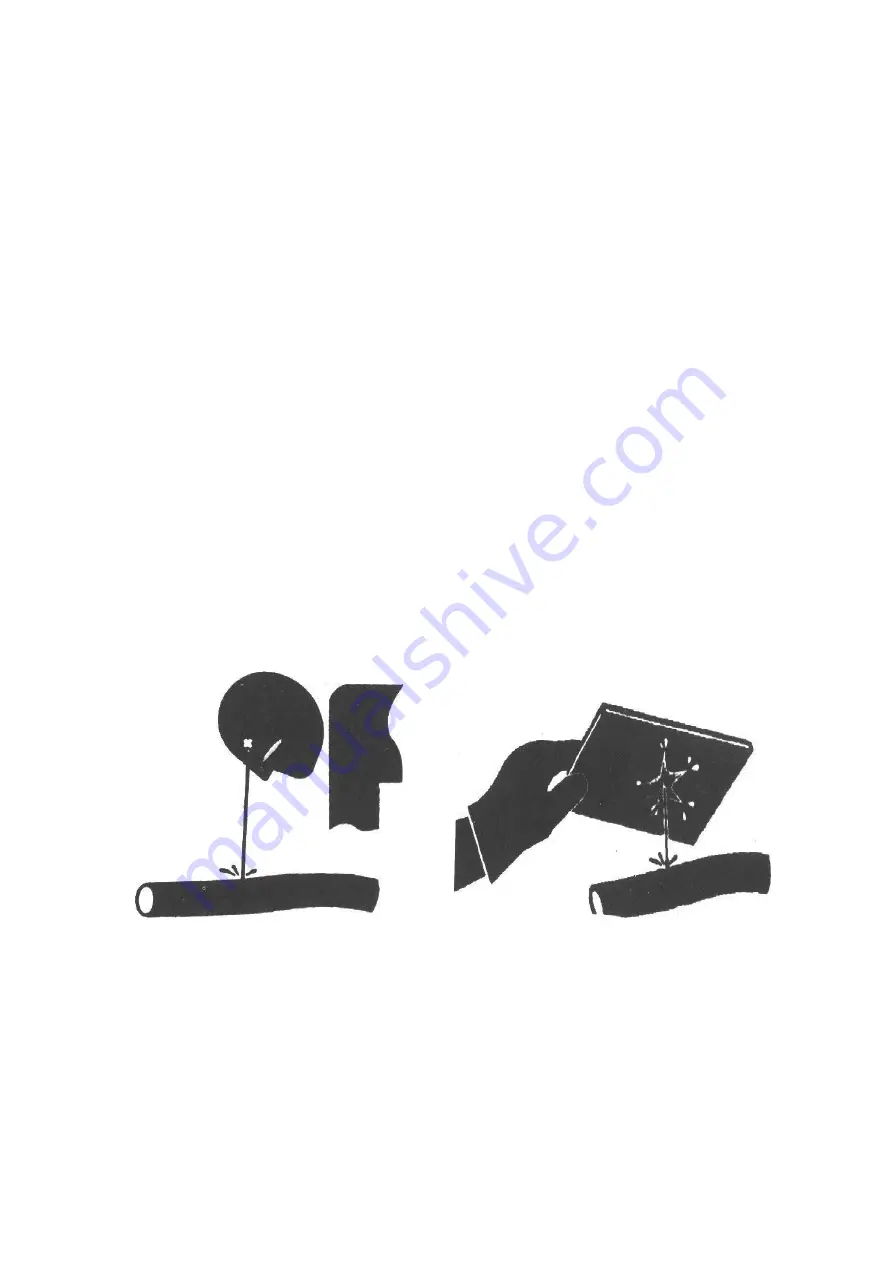

any sprayed fluid could penetrate your skin, leading to personal casualty!

Therefore, use a paperboard to check for leakage.

In addition, care must be taken to keep your hands and body away from pressure oil.

In case of accident, please immediately go to doctor with trauma experience. Any fluid into skin has to

be removed in a few hours, which otherwise may lead to gangrene.

Caution:

leaked hydraulic oil and lubricant may lead to fire or personal casualty!

1. Park machine on the flat ground. Lower the bucket onto the ground. Shift the pilot switch to Lock Turn off

the engine. Unplug the ignition key.

2. Check if there is lost part, loosened pipe clamps, twisted hose, pipeline or hose rubbing with each other. In

case of any abnormal, please replace or tighten it according to table 1-3.

3. Tighten, repair or replace any loosened, damaged or lost pipe clamps, hoses, pipes, oil cooler and flange

bolts.

Do not bend or impact any pressure pipeline.

Never install any bent or damaged hose or pipeline.

Caution: related positions of check points and the abnormalities

Summary of Contents for CTX8010

Page 1: ...1 CTX8010 MINI EXCAVATOR OPERATION PARTS MANUAL ...

Page 4: ...4 Quick hitch Narrow bucket Log grab Mechanical thumb Auger Ripper Rake ...

Page 5: ...5 Section II Main performance parameters ...

Page 13: ...12 Main pump ...

Page 15: ...14 Section IV Schematics of main valve ...

Page 16: ...15 Section V Electrical system diagram ...

Page 33: ...31 22 Lower the bucket onto the ground 23 Turn off the engine Unplug the ignitionkey ...

Page 52: ...48 ...