Dosing Device Foamdos V6

Index: 01

Date modified: 26/08/2019

OI No.: BA DW 025-00 Foamdos V6 EN.DOCX

Page 9 of 37

3.2.1

Dosing Unit

A peristaltic pump is used for dosing the foam concentrate. Peristaltic

pumps are able to transport even the smallest dosing quantities

reliably and evenly, even when air or gas bubbles are trapped in the

suction line. Rotating rollers press the dosing hose against the casing

wall, which pushes the liquid in the hose out in front of the rollers

while simultaneously feeding behind them. It is exceptionally reliable

and also very easy to operate.

The installation of a dosing valve with a non-return safety device

reliably prevents water from being pushed back or the dosing line

from running empty. The opening pressure is 0.5 barg.

ATTENTION!

Regularly check the hose of the peristaltic pump for damage according to the

maintenance protocol, or each time you refill the foam concentrate.

3.2.2

Control unit

The control unit consists of a housing with openings on the side for cooling the built-in compressor. The

electronic components are installed in the housing. The operating parameters are set at the control unit.

3.2.3

Compressor

The compressor is installed in the control housing. It pumps air in the foam line via a dosing valve. Together

with the foam concentrate and water, the massage foam is created in the foam generator.

3.2.4

System separator

The built-in system separator in accordance with DIN EN 1717 ensures that no water mixed with soap can

be sucked into the piping system in the event of a pressure drop.

3.2.5

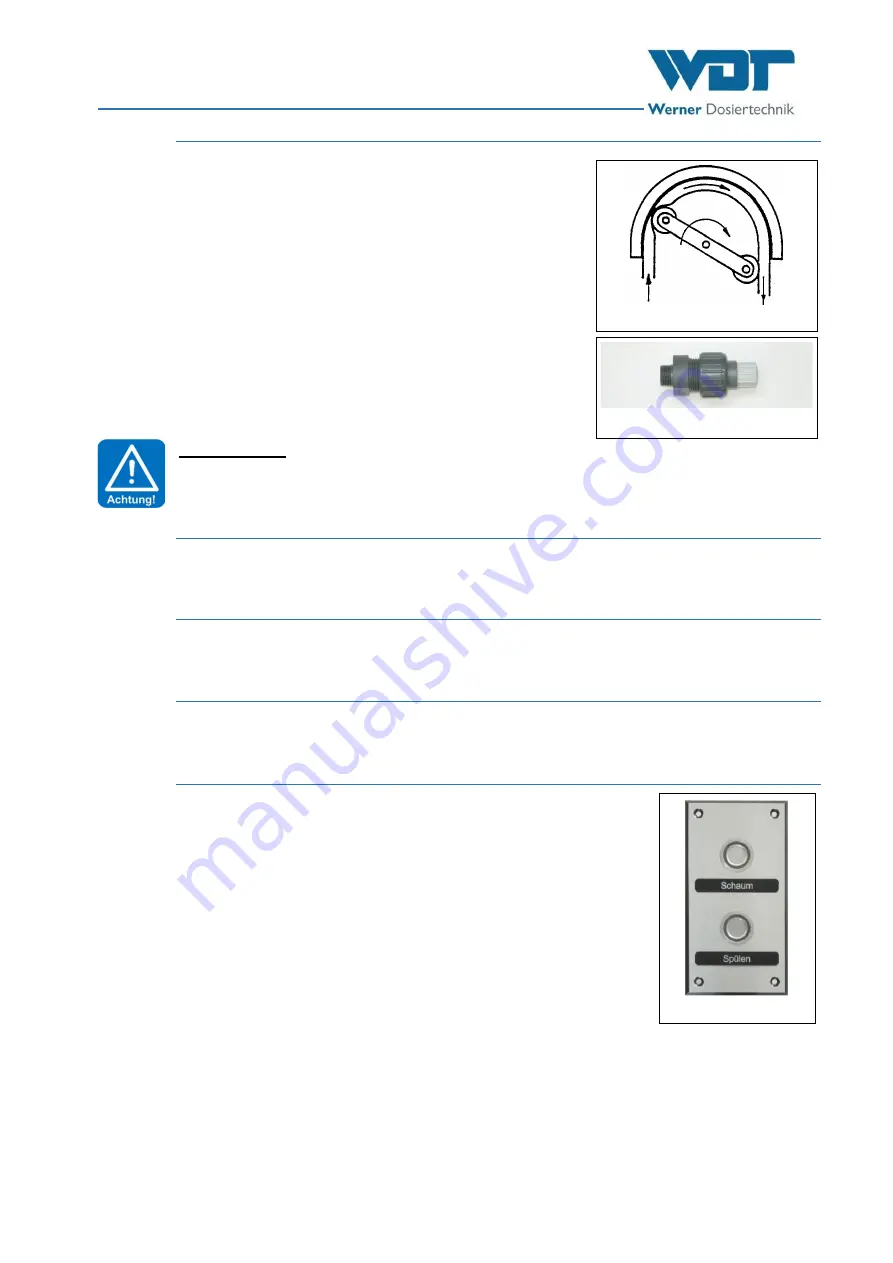

Button plate

Button plate with flush-mounted box for starting or stopping the programme.

For details about the flush-mounted box, see supplementary sheet “

BB DW

001-03 Installation flush-mounted box V2

”

Figure 2, Peristaltic pump function

Figure 3, Dosing valve

Figure 4, Button plate