GRANUDOS S5, control unit

Index: 02

Date modified: 11/05/2021

OI No.: BA SW 014-02 Granudos S5-Steuereinheit EN.docx

Page 22 of 29

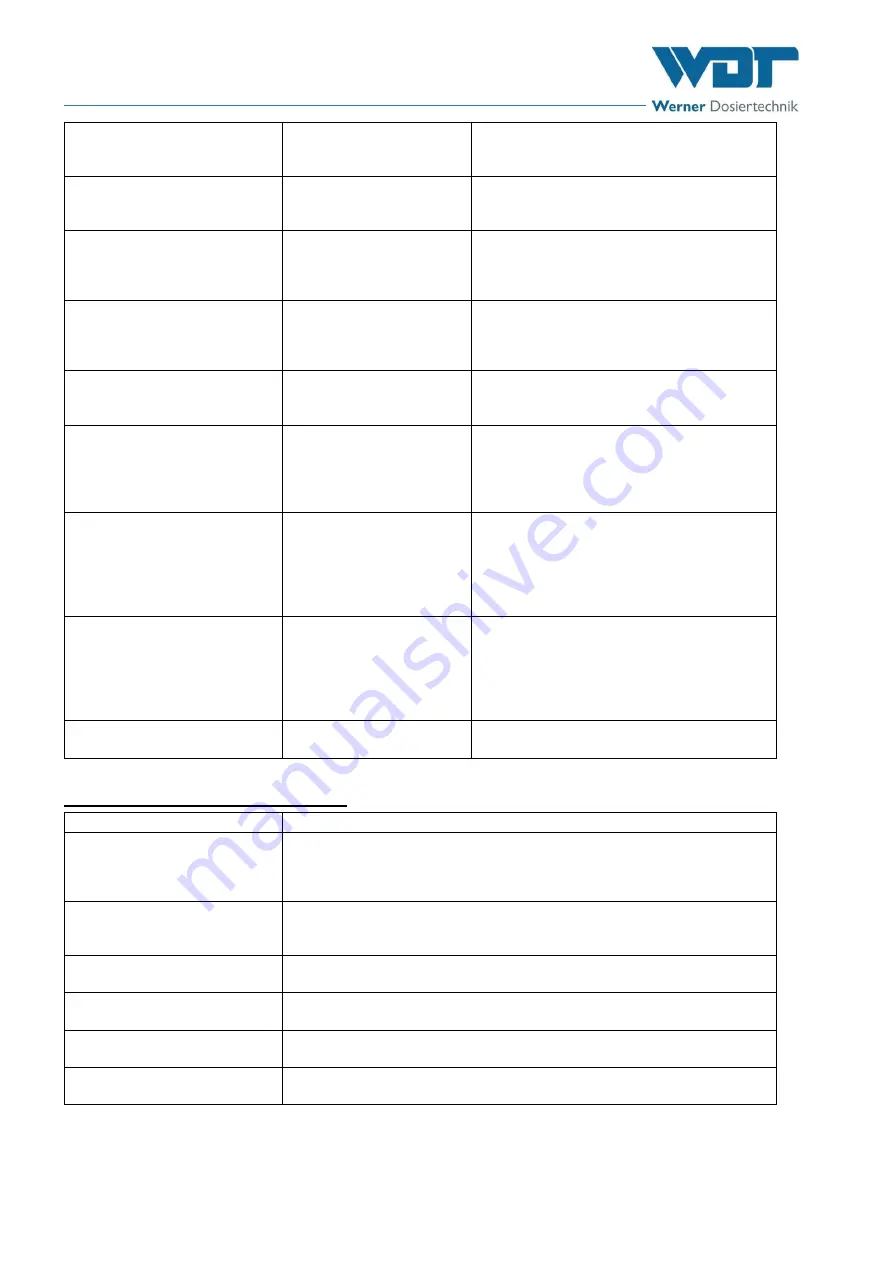

7.

Fuse F2 ALARM

Secondary fuse 24V-500mA

The fuse F2 has blown. The

dosing and booster pump stop

Renew the fuse and check whether all other fuses

show the correct fuse value. If F2 fails again,

exchange the circuit board

8.

Fuse F9 ALARM

Dosing pipe (heating)

The fuse F9 has blown. The

dosing and the booster pump

keep running.

Check the chlorine dosing pipe (heating),

exchange, if necessary, and renew the fuse.

9.

Fuse F10 ALARM

(chlorine dosing motor)

The fuse F10 has blown. The

chlorine dosing (activation) and

booster pump keep running.

Check chlorine motor for blockages, remove

blockage, as the case may be, and renew the fuse.

Check the chlorine dosing motor; exchange, if

necessary, and renew the fuse.

10.

Fuse F11 ALARM

(acid dosing pump)

The fuse F11 has blown. The

acid pump’s control is active

and the booster pump keeps

running.

Check the acid dosing pump; exchange, if

necessary, and renew the fuse.

11.

Fuse F14 ALARM

Collective fuse for sensors: Cl

empty, flow

The fuse F14 has blown. The

booster pump and the dosings

stop.

Check the “Chlorine empty” and “Flow min”

sensors in the suction pipe, renew the defective

sensor and the fuse (input test).

12.

CCT OFF, MESSAGE:

The control unit is deactivated

by the central control technol-

ogy. No dosing, no alarm mes-

sage given. The dosing device

stops.

No action, since it has been deactivated externally.

13.

“Dos-limit Cl” (chlorine)

Chlorine dosing time-out

ALARM:

The dynamic dosing time for

chlorine has been exceeded.

Chlorine dosing has

stopped, see 6.2.2

Check the function of the dosing: Dosing screw

blocked or worn? Eliminate fault or blockage. (see

also Chapter 7 for the dosing unit).

Check the dosing performance setting, increase, if

necessary.

Check the M&C control

14.

“Dos-limit pH” (acid) pH

dosing time-out ALARM:

The dynamic dosing time for

pH (

acid dosing

) has been

exceeded.

Acid dosing has

stopped, see 6.2.2

Check the function of the dosing. Eliminate fault or

blockage. (see also Chapter 7 for the respective

dosing unit).

Check the dosing performance setting,

increase,

if necessary.

Check the M&C control

15.

filter dis.

MESSAGE:

Filter disinfection is active.

No action

Malfunction without display in the device:

Malfunction

Cause

Actions

16.

The display is dark and the

device is turned off

a)

No supply voltage

Restore the supply voltage

b)

The main fuse on the housing or the front panel has blown

Renew the fuse

c)

The fuse F1 or F2 has blown

Renew the fuse

d)

The transformer is defective

Renew the circuit board

17.

The flushing tub overflows

when shutting down the

GRANUDOS

a)

Leaking floating valve:

Renew diaphragm

b)

Switch body in the suction pipe is blocked:

Foreign objects in suction pipe

Clean suction pipe

18.

The dust extraction agitator is

not running

a)

The fuse F5 has blown

Renew the fuse

b)

Check the agitator motor, including the condenser.

19.

The dust extraction flushing

valve does not switch

a)

The fuse F4 has blown

Renew the fuse

b)

Check the solenoid valve.

20.

The solenoid knocker at the

dosing hopper does not work

a)

The fuse F7 has blown

Renew the fuse

b)

Check the solenoid knocker.

21.

The booster pump does not

start up

a)

The fuse F8 has blown

Renew the fuse

b)

Check the pump, including the condenser.