Granudos 45/100-CPR Touch XL + Touch + S5

Dosing unit

Index: 02

Date modified: 06/06/2019

OI No.: BA SW 003-02 Granudos 45-100 CPR Touch+Touch+S5-Dosiereinheit EN.docx Page 40 of 58

5.2.5

Setting the water flow in the dissolving unit

The further proceedings are only possible when the device is turned on.

Turn the device on, using the main switch on the left side of the control unit. The booster

pump starts up. When the device is turned on, the pump is in permanent operation, except

when the pressure switch (41) or the level switch min (38) respond.

The washer in the screw connection (36) behind the injector (42) adjusts the injector’s

suction performance to the pressure conditions. If the water level in the flushing tank (46)

drops during commissioning, an orifice with a smaller bore must be inserted in the screw

connection.

If the water level rises, or if the flow switch's (47) switching body is not clearly pushed

upward, an orifice with a larger bore is required, or the orifice must be removed entirely.

An orifice with 6mm is installed by the factory; orifices with 5.5mm and 7mm are available

in the enclosed spare parts bag.

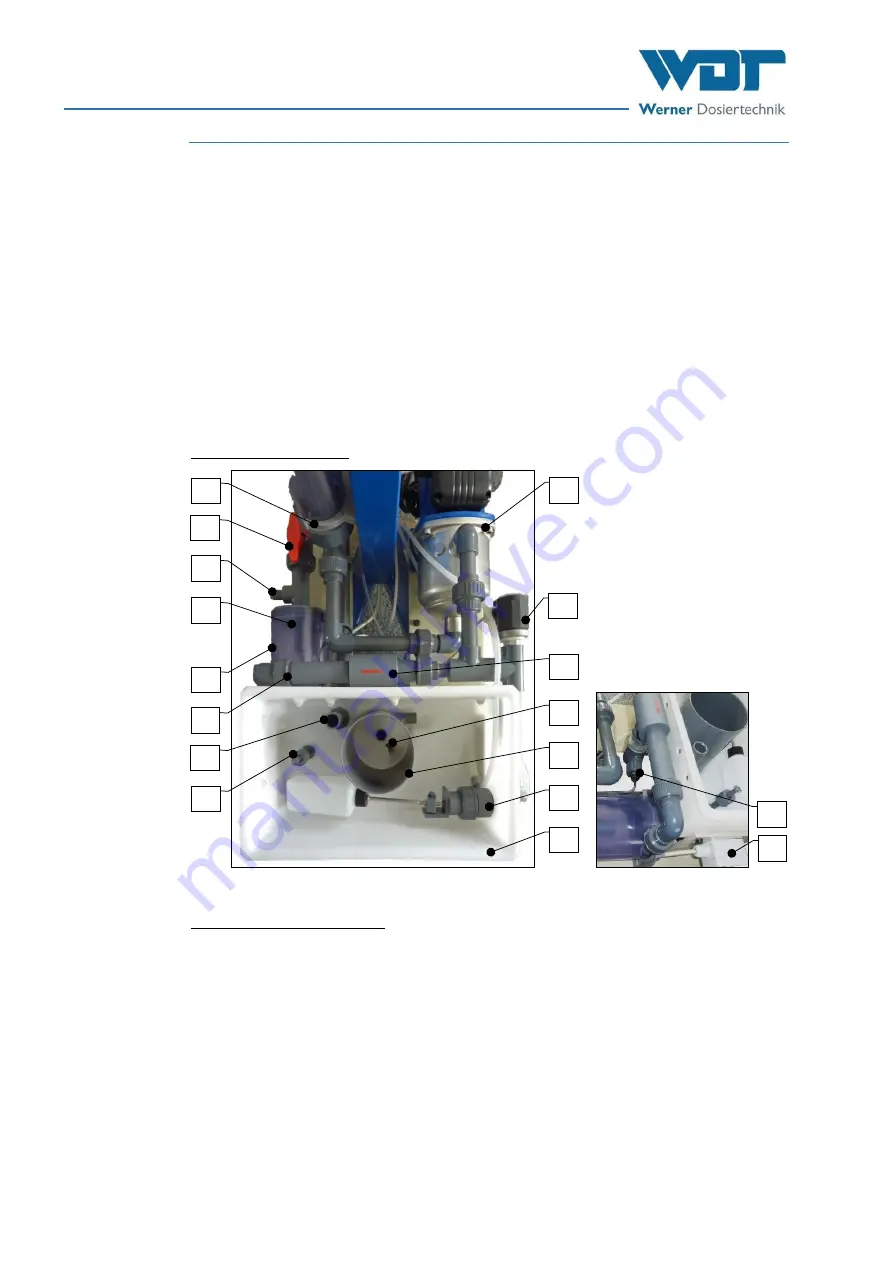

Overview dissolving unit

The dissolving unit consists of:

31.

Dirt filter d75mm

32.

Outflow ball valve for booster water

33.

Connection for manometer

34.

No chlorine switch / sensor on the

cyclone (optional, not illustrated)

35.

Dissolving and mixing cyclone

36.

Screw connection with washer

37.

Overflow flushing tank

38.

Level switch min./max. Flushing tank

39.

Booster pump (different designs)

40.

---

41.

Pressure switch

42.

Injector

43.

Dosing valve for pH reducer (acid)

44.

Flushing pipe

45.

Float control valve flushing tank Inlet

46.

Flushing tank

47.

Flow switch flushing tank

48.

Connection socket for the switches

49.

Motor for dust extraction (not

illustrated, see Figure 7)

50.

Fan for dust extraction (not illustrated,

see Figure 7)

Figure 28, Dissolving unit from above (without dust extraction)

41

42

46

45

44

39

43

32

33

34

35

37

31

38

36

48

47