Tradition verpflichtet

9

PE 4040

BEL

T DRIVE - MADE IN GERMANY

F 6

- Drive setting

Sub-chassis

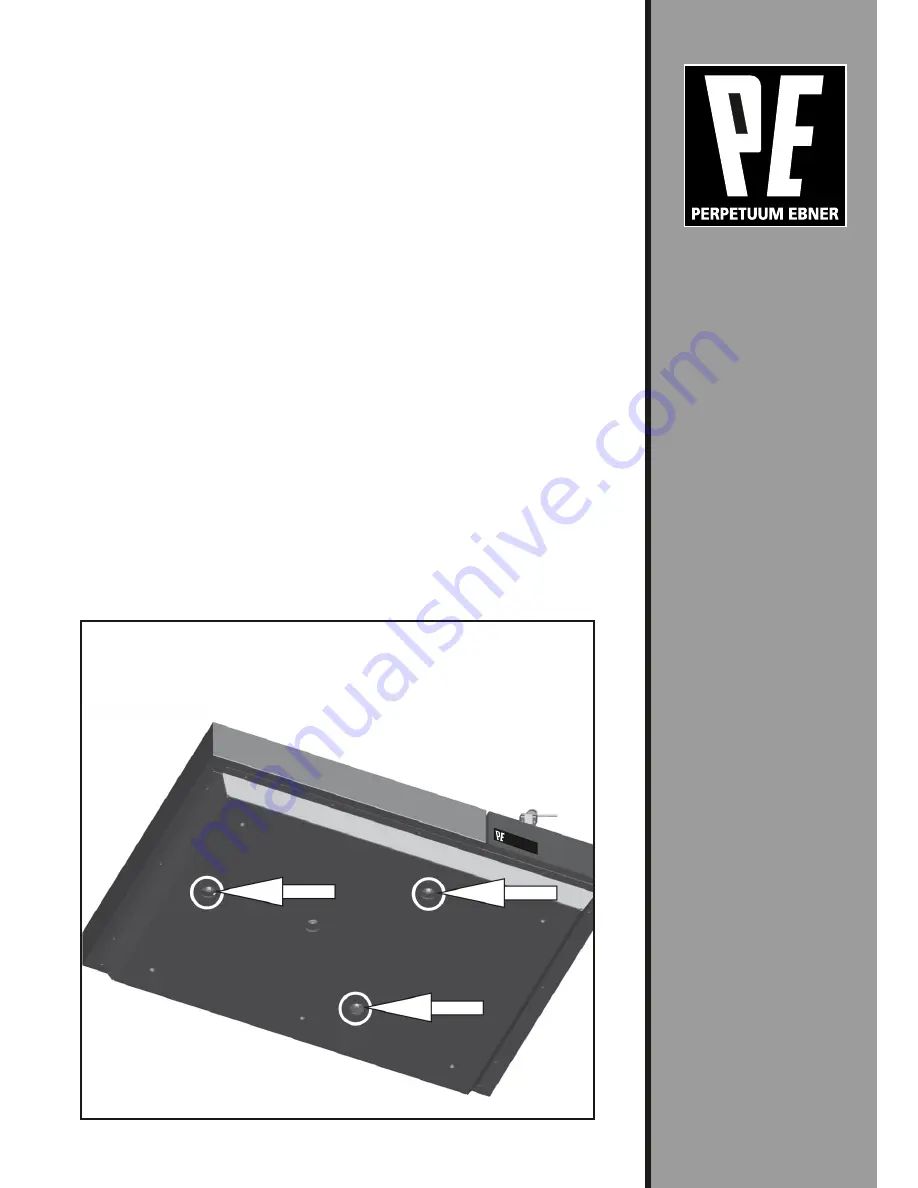

b.) Adjusting the sub-chassis drive:

The sub-chassis is already preset in the way that there is

a constant distance of approx. 5 mm between the

underside of the platter and the underside of the tone

arm socket.

This distance has the purpose to allow the sub-chassis

to freely oscillate in all directions.

The installation of our suspension bolts permits the sub-

chassis to only oscillate vertically in a limited and

controlled way (see fig.

F 6

with bottom tray).