weaverleathersupply.com

800-932-8371

11

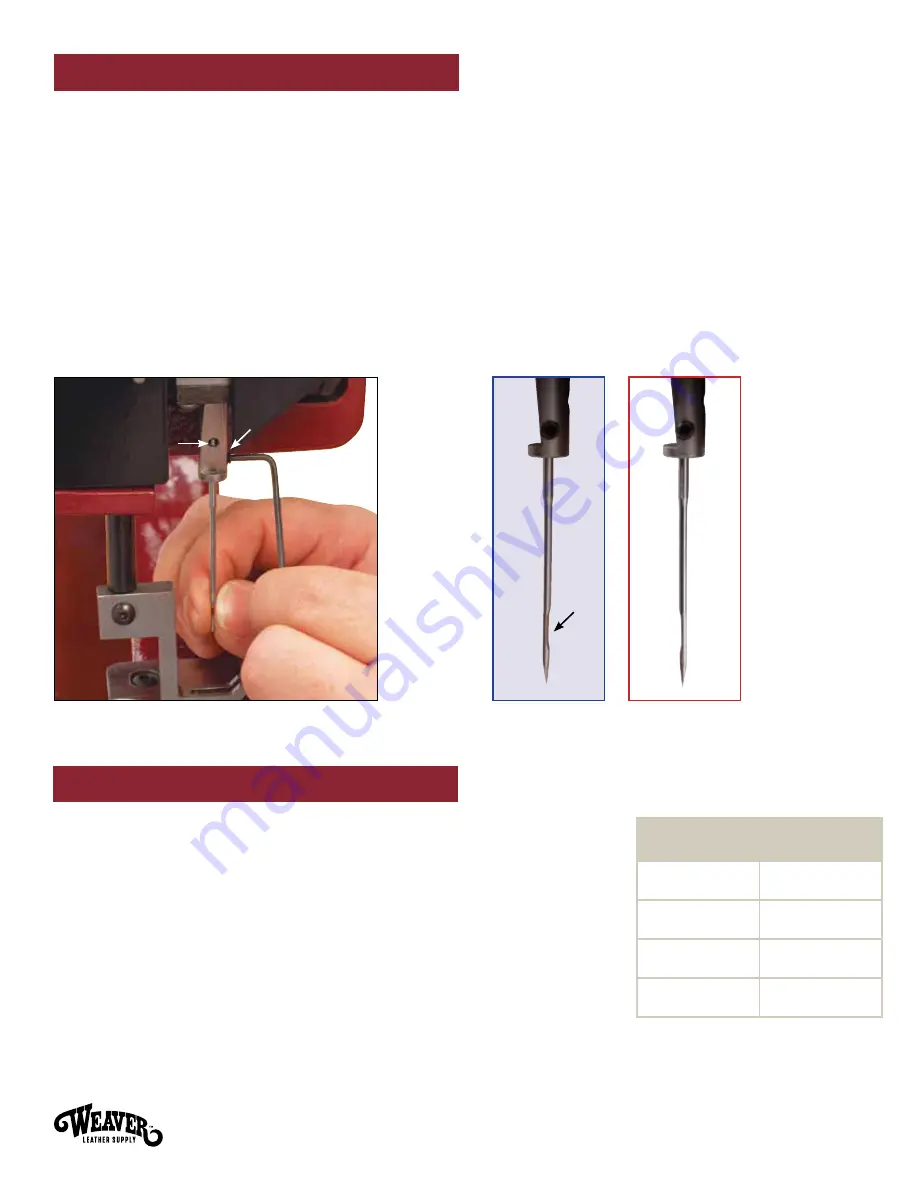

CHANGING THE NEEDLE

Refer to the Thread & Needle Chart below to ensure you are using the correct needle

for the thread you are using.

1) Loosen the Needle Screw

(D)

with the Allen wrench provided and remove the old needle.

(Figure 26)

2) Be sure the new needle is positioned correctly with the Scarf

(E)

facing to the right.

Please note:

You should be able to see the needle in the round opening of the needle bar.

Troubleshooting Tip:

If you experience sewing difficulties, including skipped stitches,

failure to pick up the bobbin thread, and frayed thread, try changing your needle. Bent

or dull needles may be responsible.

Correct

Needle

Position

Wrong

Needle

Position

D

D

E

E

Figure 26

Round

Round

Opening

Opening

of the

of the

Needle Bar

Needle Bar

NEEDLE & THREAD CHART

The Master Tool Cub uses 794S (Chisel Point), 794LR (Twisted

Chisel Point) and 7X3R (Round Point) System Needles:

• Chisel Point & Twisted Chisel Point Needles –

Recommended for leather or non-wovens

• Round Point Needles – Recommended for woven materials

Helpful Tips

• When ordering needles indicate 794S or 794LR for leather

or 7X3R for nylon.

• We recommend using Schmetz

®

brand needles for superior

performance.

• Be sure to use the correct needle for the thread being used.

NEEDLE

SIZE

THREAD TOP/

BOTTOM

230

346/277

200

277/207

180

207/138

160

138/92