www.webasto.us

31

Webasto Product N.A., Inc.

DBW 2010/2020/300 COOLANT HEATERS

FUNCTIONAL ADJUSTMENTS

6.

FUNCTIONAL ADJUSTMENTS

6.1

G

ENERAL

This section describes the tests and adjustments on the

heater in installed and removed condition to prove its

serviceability.

WARNING: The heater must not be

operated in closed areas like garages or

workshops with no exhaust ventilation

facilities.

To prevent fires do not switch heater on

with burner swung open.

6.2

A

DJUSTMENTS

6.2.1

A

DJUSTMENT

OF

CO

2

C

ONTENTS

It is allowed to change the manufacturer’s setting for

combustion air quantity by rotation of the setting ring.

Measurement of the CO

2

value of the exhaust gas must

be performed followed by an adjustment of the

combustion air quantity as required in case of:

– repairs to the burner head

– irregularities in combustion

– functional checks

– nozzle replacement

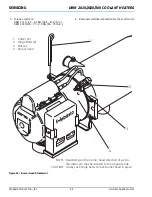

6.2.1.1 S

ETTING

PROCEDURE

– Measure control unit power supply voltage

– Operate heater for approximately 5 min.

– Measure CO

2

contents and compare with CO

2

diagram

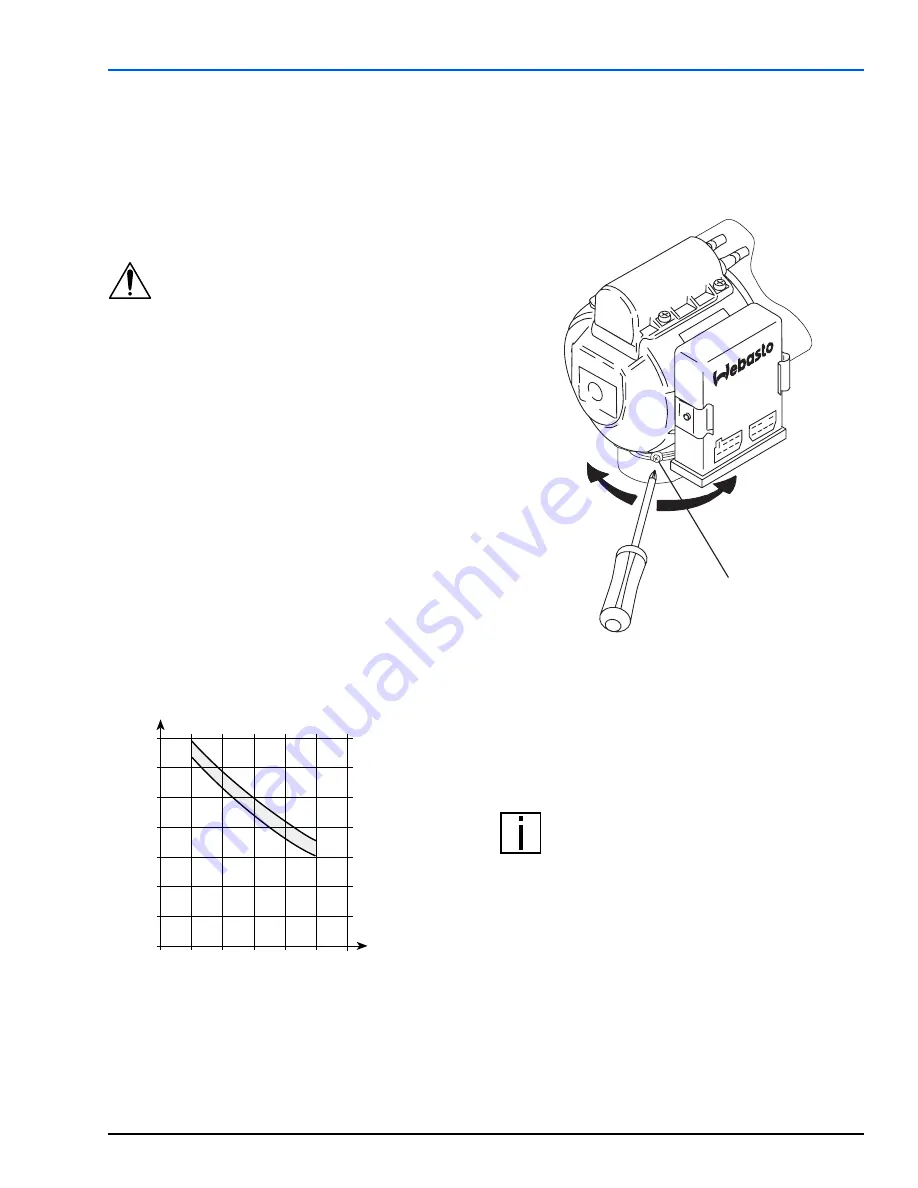

Figure 21:

Combustion Air / Fuel Mixture Adjustment

– Loosen locking screw (refer to Figure above) and

reposition shutter with locking screw until rated

value is obtained

– Tighten locking screw with 1.0 +0.5 Nm and apply

screw seal varnish to mark new position

NOTE:

CO

2

setting depends on fuel (viscosity)

and on geodetic altitude (0.1% per 100 m).

If proper setting cannot be obtained, proceed as follows:

– Check burner head air side for damage and replace if

required

– Check fuel pump pressure and replace pump if

required

– Check fuel filter and strainer in fuel pump for

contamination and replace if required

– Adjust fuel pressure

– Replace fuel nozzle

– Measure burner motor speed

DBW 20

1

0

(Nozzle: 0.35 gph)

DBW 2020

(Rev.

.33)

DBW 300

Fuel pump pressure set to 10 bar (145 psi)

CO

2

(V

o

l.

-%

)

18

20

22

24

26

28

30

6

7

8

9

10

11

12

13

9

10

11

12

13

14

15

Voltage

CO

2

- setting at 500 m above sea-level

+

–

CO

2

CO

2

Locking screw