www.webasto.us

45

Webasto Product N.A., Inc.

DBW 2010/2020/300 COOLANT HEATERS

SERVICING

8.6

V

ISUAL

I

NSPECTIONS

AND

R

EGULATIONS

FOR

I

NSTALLATION

8.6.1

C

ONNECTION

TO

V

EHICLE

C

OOLING

S

YSTEM

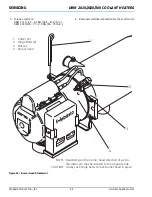

The installation of the heater should be in a location as

low as possible to ensure self-venting of the heater and

circulation pump. This applies in particular for the

circulation pump because it is not self-priming.

The cooling system coolant capacity must be at least 10

liters. The vehicle cooling system or the separate heating

circuit must use only pressure relief valves with an

opening pressure of at least 0.4 bar and of max. 2.0 bar.

It is a basic requirement to use the coolant hoses supplied

by Webasto, otherwise the hoses must at least meet the

specifications of DIN 73411. The hoses have to be

installed free of kinks and for proper venting in an

inclination. Hose connections must be secured against

slippage with hose clamps.

NOTE:

The specified tightening torques of the

hose clamps used must be complied with.

Prior to the heater’s first operation or after replacement

of the coolant, attention must be paid to carefully bleed

the cooling system. Heater and lines must be installed so

that static venting is guaranteed.

Improper venting may cause malfunctions by overheating

in equipment operation.

Proper venting may be identified by a circulation pump

almost noiseless in operation.

8.6.2

C

ONNECTION

TO

V

EHICLE

F

UEL

S

YSTEM

Fuel is tapped from the fuel reservoir of the vehicle or

from a separate fuel tank.

8.6.2.1 F

UEL

L

INES

In order to avoid air from being captured in fuel lines,

they should only be installed with an incline. The fuel

line joints are to be secured against slipping with hose

clamps should no screwed mechanical unions be in use.

Should fuel hoses be installed always use the hoses

supplied or offered by Webasto. If other hoses are used

they must at least meet the specifications of DIN73379-

1C; type 3. Fuel hoses must not be kinked or twisted

and must be secured with clamps every 25 cm (10 in.).

Also, fuel lines may be used consisting of materials

standard in the manufacturing of vehicles, e.g. steel or

plastic lines made of unhardened, light and temperature

stabilized PA11 or PA12 (e.g. Mecanyl RWTL) according

to DIN 73378 observing the applicable jointing

instructions.

Basic rules for the routing of fuel lines are:

• Protect against undue temperatures.

WARNING: In overheat condition the

heater outer shell may reach the flash point

temperature of Diesel fuel!

• Protect lines from stone strikes and debris that could

damage them and result in leakage.

• Dripping or evaporating fuel must not be

allowed to accumulate or ignite on hot

components or electrical equipment.

The installation of an additional fuel pump is not

allowed.

Fuel lines permissible dimensions:

• Inner diameter for suction and return line: 6 mm

(except Scholastic Heater™).

• Scholastic Heater™ inner diameter for suction line:

3/16 inches.

• Maximum permissible length for each suction and

return line: 10 m

• Maximum permissible suction height: 2 m

• Maximum permissible priming pressure: 0.3 bar for

suction and return line.

8.6.2.2 F

UEL

F

ILTER

A fuel filter supplied as deliverable item or cleared for use

by Webasto is to be fitted.

Installation position possibly vertical with horizontal

direction of flow. To avoid operating malfunctions

replace filter or filter cartridge once a year or more often

if fuel is contaminated.

8.6.3

C

OMBUSTION

A

IR

S

UPPLY

CAUTION: Observe official regulations

concerning the installation (see 1.6).

Combustion air must under no circumstances be

extracted from rooms with persons. The combustion air

inlet must not point towards the forward direction of

motion.

It must be located so that no clogging by contamination,

impact of snow, or intake of splash water is to be

expected.

The combustion air intake and exhaust outlet is to be

located so that no air pressure difference builds up in any

operating condition of the vehicle.