Thermo 90

8 Servicing

807

8.6.3.1 Installation Location

It is advantageous to mount the dosing pump in a cool

location as near as possible to the tank. The ambient

temperature must never 20° C for fuel and

+40° C for Diesel operated installations at any time while

in operation. The maximum pressure at the tapping

location must be below 1.5 bar.

Dosing pump and fuel lines must not be installed in

locations exposed to heat radiated by hot vehicle

components. A heat shield is to be provided as required.

8.6.3.2 Installation and Attachment

The dosing pump is to be attached with anti-vibration

mounts. The installation location is limited according to

Fig. 807 to ensure sufficient self-venting capability. Due

to the danger of corrosion the plug connection between

dosing pump and dosing pump cable loom may only use

Webasto original parts.

8.6.4 Fuel Filter

If there is the probability of contaminated fuel, only the

Webasto filter, Order No. 487 171, may be used. The

filter can be installed anywhere between the vertical and

horizontal positions, but must be installed in the direction

of flow.

8.6.5 Combustion Air Supply

Combustion air must under no circumstances be

extracted from rooms with persons. The combustion air

inlet must not point towards the forward direction of

motion. It must be located so that no clogging by

contamination, impact of snow, or intake of splash water

is possible.

The combustion air intake line (inner diameter at least

30 mm) may have a length from 0.5 m to 5 m with several

bends of a total of 360°. Smallest bending radius is

45 mm.

The combustion air inlet must not be located above the

exhaust outlet.

NOTE

The combustion air intake line is to be routed in a

downwards direction. If this is not possible, a water drain

hole (4 mm Ø) must be provided at the lowest point.

If the heater is located near the fuel tank in a common

installation compartment, combustion air must be taken

in from, and the exhaust routed to, the exterior. The

feed-throughs must be splash waterproof.

If the heater is located in a closed installation box,

a vent port of at least 6 cm

2

is required. If the temperature

in the installation box exceeds the permitted ambient

temperature of the heater (see Technical Data), the vent

port must be enlarged consulting Webasto.

8.6.6 Exhaust Line

The exhaust line (inner diameter 38 mm) may have a

length from 0.5 m to 5 m and be routed with several bends

(a total of 360°, smallest bending radius 85 mm). The

exhaust muffler is mandatory and to be mounted near the

heater.

In order to ensure the angle of 90° ± 10°, an attachment

is required not further than 150 mm away measured from

the exhaust pipe end.

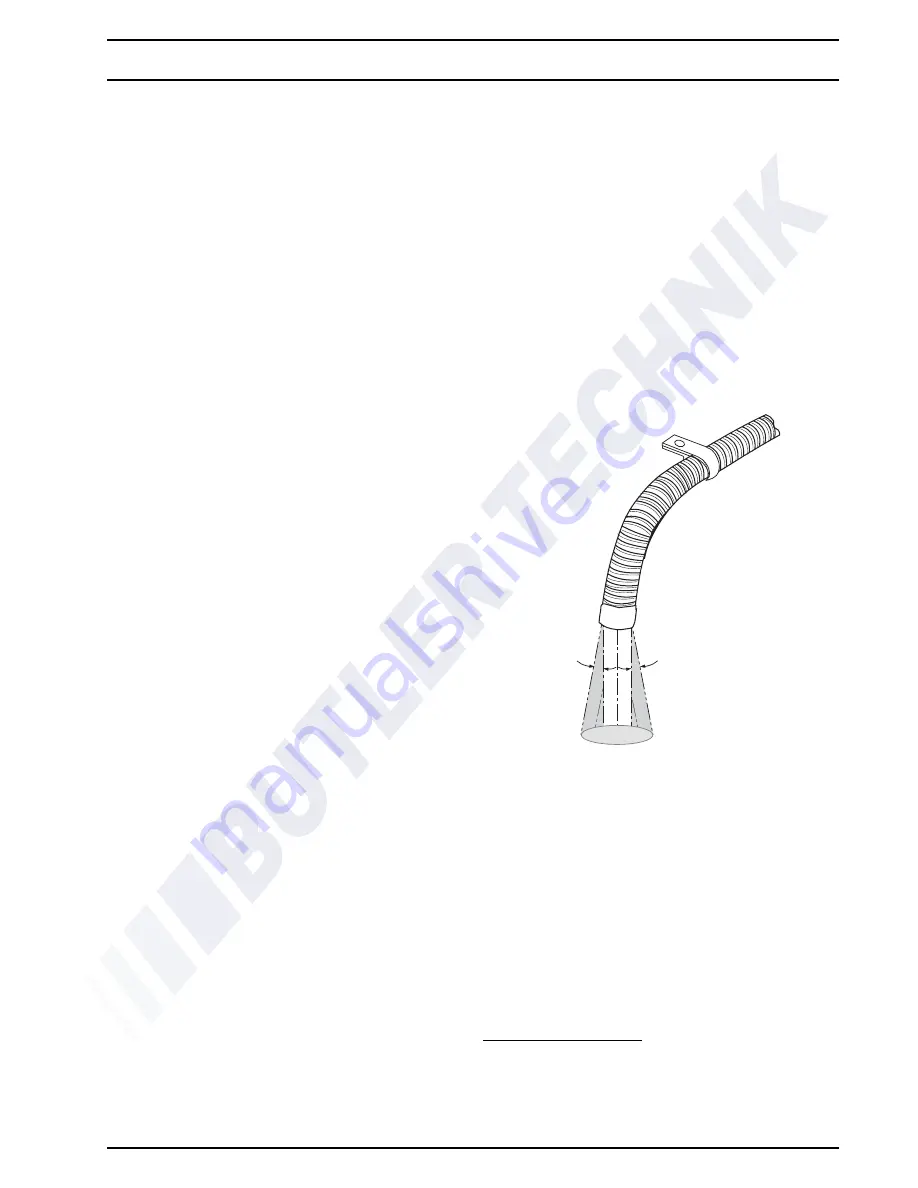

Fig. 808 Exhaust Muffler, Direction of Flow

The exhaust pipe outlet opening must not point in the

direction of motion (see Fig. 808).

The exhaust pipe outlet opening must be located so as not

to allow clogging by snow or mud.

Rigid exhaust-line pipes can be mode of unalloyed or

alloyed steel, but must have a minimum wall thickness of

1.0 mm. Flexible exhaust pipes must be made only of

alloyed steel. The exhaust pipe is secured to the air heater

with a clamp. For further requirements refer to official

regulations.

For Thermo 90 TRS only: For official regulations

concerning the exhaust pipe installation refer to Technical

Information E3 - 5.10 (Order No. 776 623).

10

°

10

°

Exhaust exit direction

nearly vertical 90° ± 10°

Summary of Contents for Thermo 90

Page 9: ...1 Introduction 104 Page free for notes ...

Page 13: ...2 General Description Thermo 90 204 Page free for notes ...

Page 18: ...Thermo 90 3 Functional Description 305 Page free for notes ...

Page 20: ...4 Technical Data Thermo 90 402 Page free for notes ...

Page 26: ...6 Functional Tests Thermo 90 602 Page free for notes ...

Page 41: ...Thermo 90 8 Servicing 809 Page free for notes ...

Page 53: ...10 Packaging Storage and Shipping Thermo 90 1002 Page free for notes ...