8 | Fuel Supply

22

8.4

Fuel Lines

CAUTION

Do not use biodiesel with copper fuel lines.

Failure to follow this instruction will result

in damage to the heater and fuel system.

Since the lines normally cannot be routed with a

constant rising gradient, the internal diameter must

not be allowed to exceed a specific size. Air or gas

bubbles will accumulate in lines with an internal dia-

meter that is larger than is provided. These will cause

malfunctions while the heater is operating if the lines

sag or are routed downwards. The lines should not

be routed downwards from the metering pump to

the heater.

Unsupported fuel lines must be secured to prevent

them from sagging. The fuel line must be installed in

such a way that it cannot be damaged by flying road

debris and high temperatures, i.e. close to the ex-

haust line. The fuel line must be secure at the con-

nections using hose clamps to prevent slipping.

NOTE

Always cut fuel lines in such a way that you

won’t cause burrs. Be sure to check for,

and remove burrs after each fuel line cut.

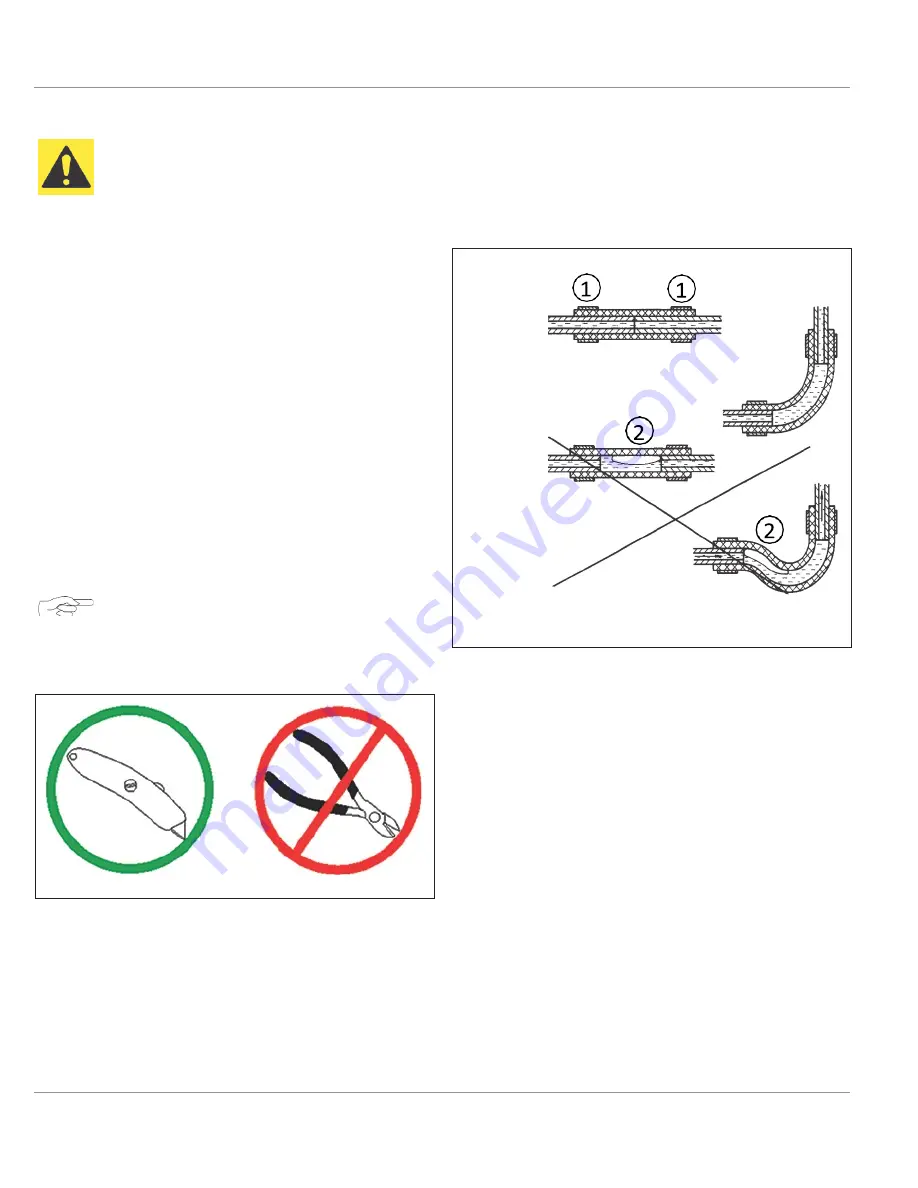

The correct procedure for connecting fuel lines is

shown below. Ensure that there are no leaks. The

line must be routed to be protected against damage

(e.g. stone impact). The fuel line must be routed in

cool areas to prevent the formation of bubbles due

to heat sources.

Only steel, copper and plastic lines made of plasti-

cized, light and temperature-stabilized PA 11 or PA

12 (e.g. Mecanyl RWTL) may be used for the fuel

lines.

The lines should not be routed downwards from the

fuel metering pump to the heater. Fuel lines must be

secured to prevent them from sagging.

Fig. 20: Fuel Line to Coupler Hose Location

1 Clamp

2 Bubble

Summary of Contents for thermo top evo

Page 46: ...15 NOTES NOTES ...

Page 47: ......