16

7 | Coolant System

NOTE

IMPORTANT

The heater comes pre-assembled; however,

if direction of the water inlet or outlet

needs to changed use the following torque

specification.

5X15mm self-tapping screw, torque to 5 lb-

ft (7 Nm).

Fig. 11: Coolant Connections at Heater

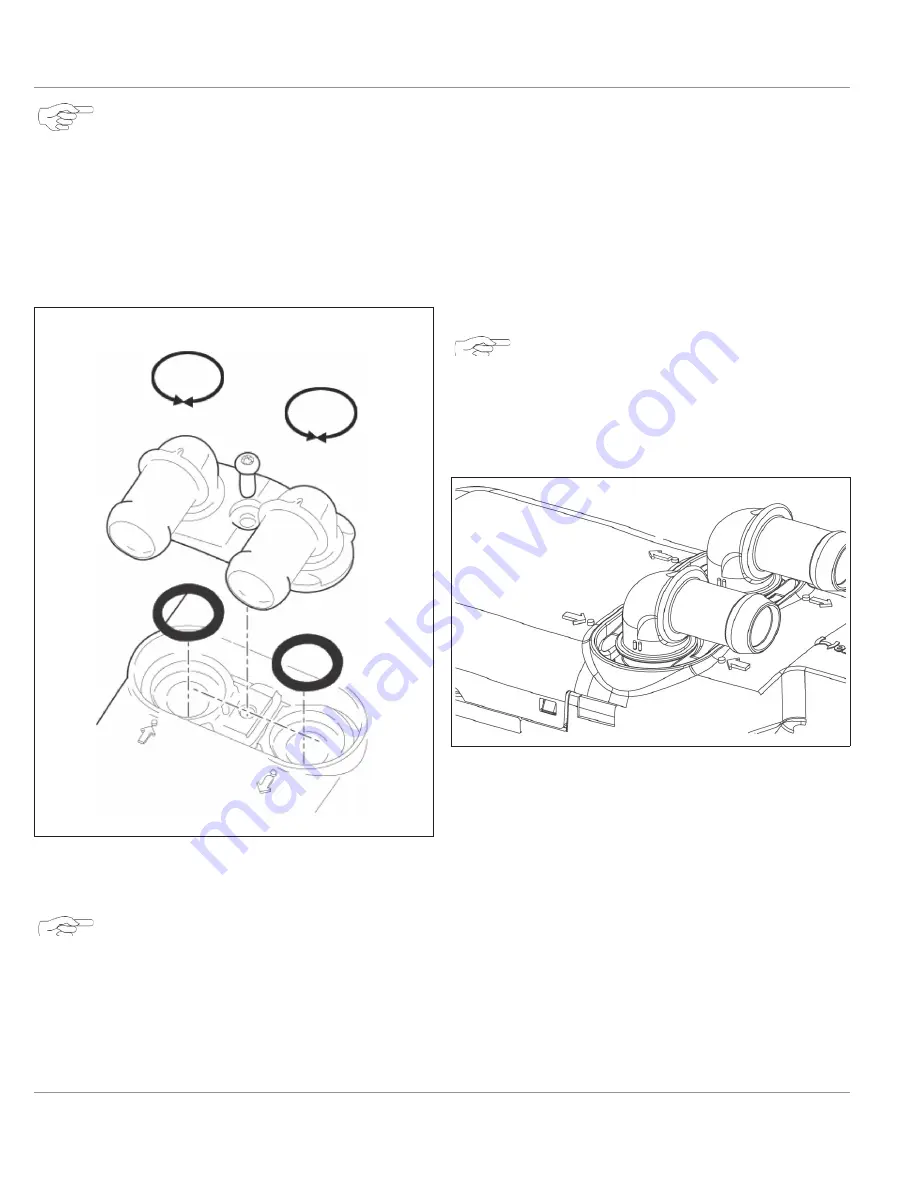

7.3

Coolant System Connections

NOTE

The hose clamps must be tightened with a

torque of 40 lb. in. (4.5 Nm). The use of sil-

icone hose requires special hose clamps.

The coolant quantity in the coolant circuit corres-

ponds to the minimum volume specified in Technical

The heater should preferably be integrated into the

coolant system close to the inlet of the vehicle heat

exchanger.

Connect the heater to the vehicle coolant system as

shown in Coolant System on page 15.

Route coolant hoses in such a way to avoid kinks

and pinches. Be sure the hoses run slightly uphill

from the heater to help in bleeding the coolant sys-

tem.

Secure hose connections using hose clamps.

NOTE

When integrating the coolant hoses in the

coolant circuit, the correct direction of flow

of the coolant must be ensured. Use the

coolant flow arrows on the heater when in-

stalling coolant hoses.

Fig. 12: Flow Direction Arrows

Care must be taken to bleed the cooling system be-

fore the heater is started for the first time or after re-

filling with fresh coolant. Heater and lines should be

installed in such a way as to ensure static bleeding.

Insufficiently bleeding the coolant circuit can lead to a

malfunction due to overheating or to frequent switch-

on/switch-off cycles of the heater.

Separate the heater supply and return connections

at the engine as far apart as possible for optimum

engine heating and heater performance.

Summary of Contents for thermo top evo

Page 46: ...15 NOTES NOTES ...

Page 47: ......