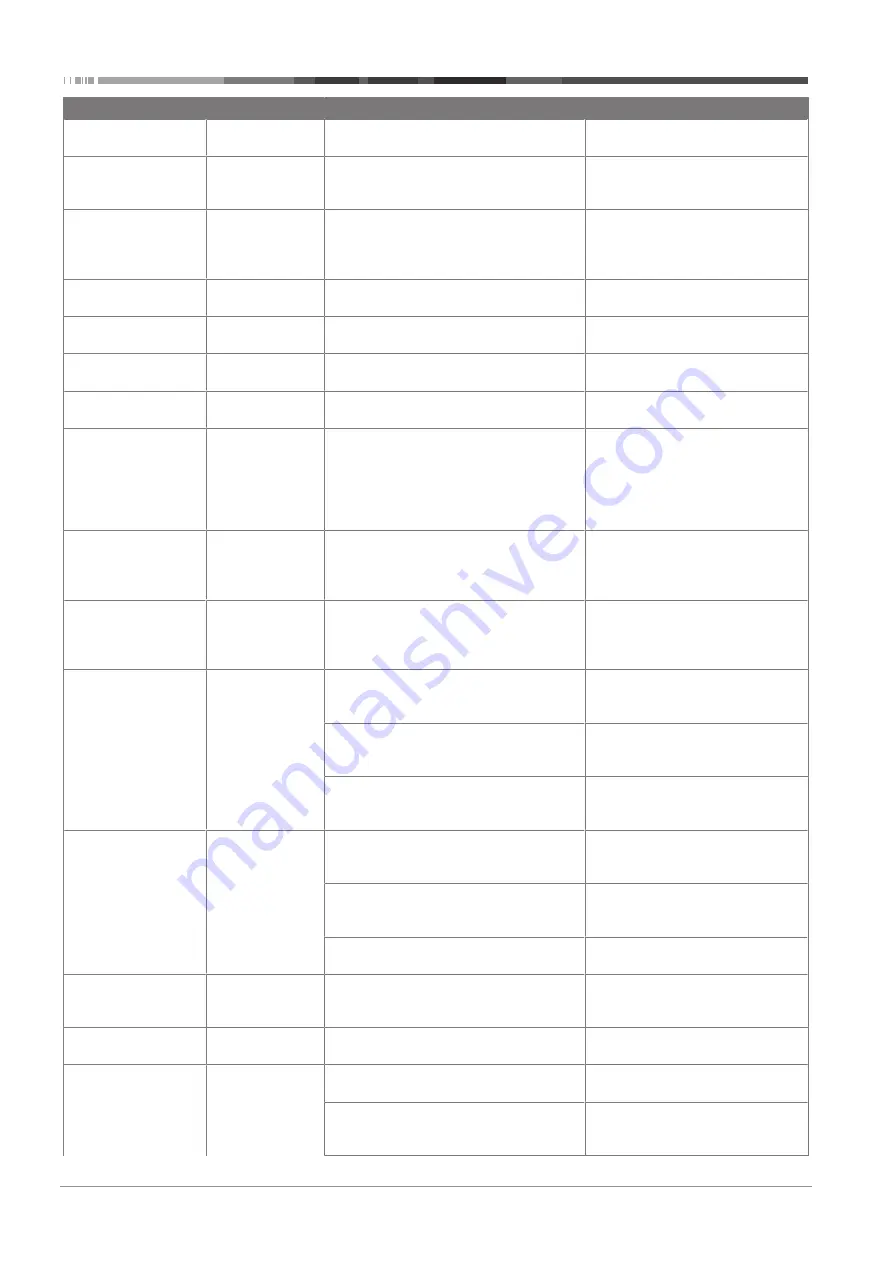

10 | Status / Error message table

8 / 10

2112899A OI Ti22 ProX

Screen

LED “Alive”

Possible cause

Correction

A08 - High pressure

compressor 4

9x flashing,

pause...

See A02

See A02

A09 - Cabin temperat-

ure sensor

10x flashing,

pause...

Cabin temperature sensor defective, break /

short-circuit in electrical circuit, cabin tem-

perature sensor not connected.

Connect or replace the cabin temper-

ature sensor.

A10 - Cold water tem-

perature sensor

11x flashing,

pause...

Cold water temperature sensor defective or

break / short-circuit in electrical circuit.

Replace the sensor. If this does not

solve the problem, please contact

your authorised Webasto Marine

dealer or service partner.

A11 - Low pressure

compressor 5

12x flashing,

pause...

See A01

See A01

A12 - High pressure

compressor 5

13x flashing,

pause...

See A02

See A02

A13 - Low pressure

compressor 6

14x flashing,

pause...

See A01

See A01

A14 - High pressure

compressor 6

15x flashing,

pause...

See A02

See A02

A15 - Cold water flow

16x flashing,

pause...

The flow monitor identifies insufficient cold

water flow 5 seconds after the cold water

pump is switched on. Cold water circuit is

blocked or wire break at flow monitor if the

parameter "flow monitor" in the Deactiva-

tion menu is set to Normally open (NO).

Check cold water circuit. If a flow

monitor is not installed, you must de-

activate the flow monitor parameter

using the control element.

Refer to Setting level 3 (parameter

menu).

CA11 - compressors de-

activated

n.a.

Set compressor(s) in the control setting are

not active.

Check settings on the control ele-

ment. At least one compressor must

be set as active. See Setting level 3

(parameter menu)

Init - data communica-

tion

17x flashing,

pause...

Data communication: Electrical wiring de-

fective. Power circuit interruption/short cir-

cuit.

Check cables and connections of pc-

board and of control element.

Replace defective connection cable,

control element or pc-board.

No display on screen;

compressor and sea wa-

ter pump not running.

n.a.

Fuse faulty or break / short-circuit in this

electrical circuit.

Please contact your authorised

Webasto Marine dealer or service

partner.

Pc-board damaged by high voltage.

Please contact your authorised

Webasto Marine dealer or service

partner.

Electronic relay (TRIAC) defective.

Please contact your authorised

Webasto Marine dealer or service

partner.

Compressor not run-

ning.

n.a.

Compressor defective or break / short-circuit

in compressor wiring.

Please contact your authorised

Webasto Marine dealer or service

partner.

Compressor overload or overload protection

element on top of compressor defective.

Please contact your authorised

Webasto Marine dealer or service

partner.

Incorrect compressor settings.

Check settings. At least one com-

pressor must be set as active.

Seawater pump(s) start

up directly after the

control is switched on.

n.a.

Wiring of seawater pump and cold water

pump interchanged.

Check electrical wiring.

Compressor keeps cut-

ting in and out.

n.a.

Too little cold water.

Check cold water system for leaks.

No or insufficient cool-

ing or heating capacity.

n.a.

Poor air or water flow, soiled or circulation

blocked.

Secure adequate air or water flow.

Refrigerant shortage.

Please contact your authorised

Webasto Marine dealer or a refriger-

ant specialist.