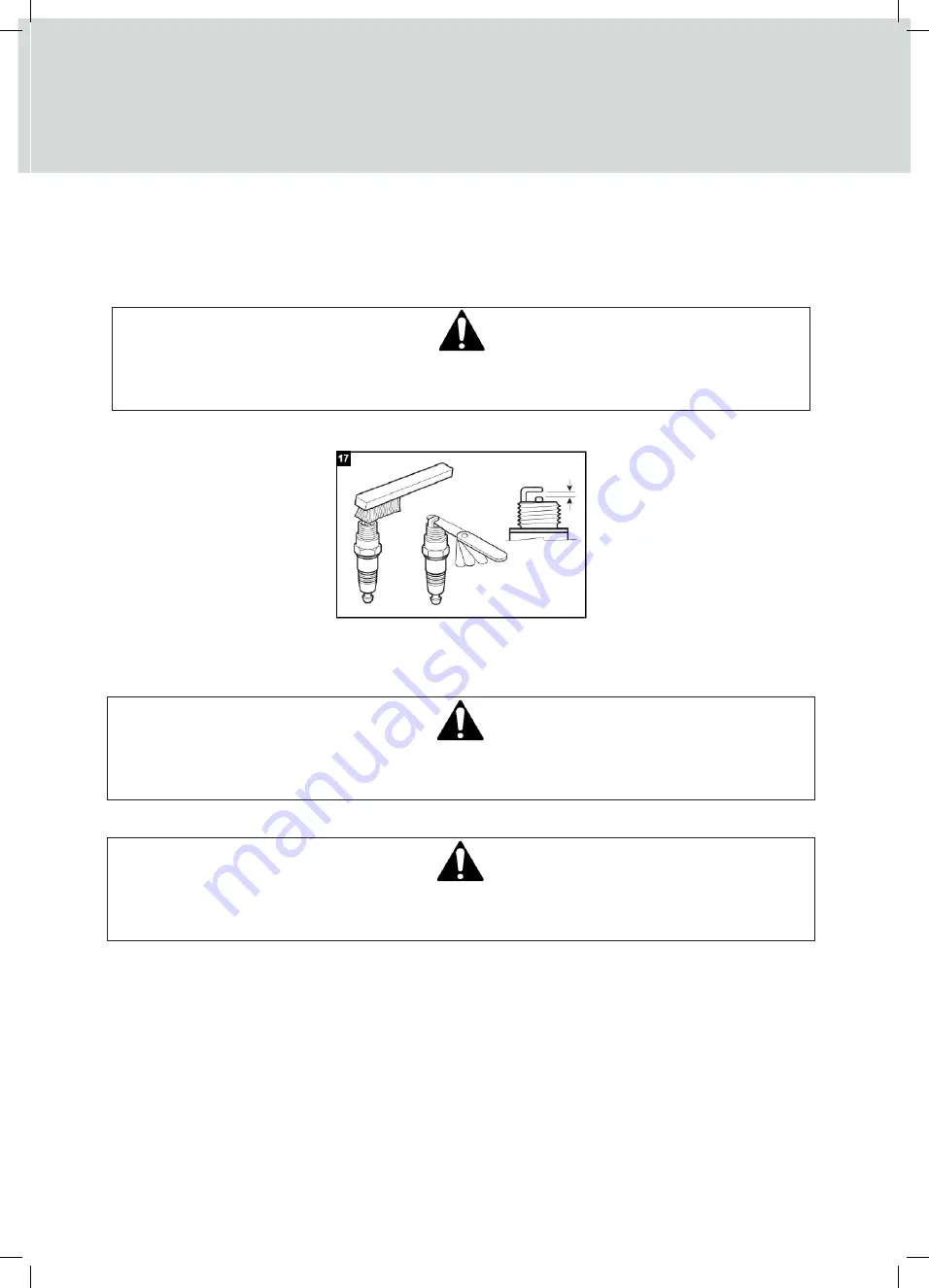

SPARK PLUG

To ensure proper engine operation, the spark plug must be properly gapped and free of deposits.

1.

Do not attempt to remove the plug from a hot engine in order to avoid possible damage to the threads.

2.

Remove the spark plug cap.

WARNING

If the engine has been running, the exhaust (muffler) will be very hot. Be careful not to touch the exhaust

(muffler).

3.

Visually inspect the spark plug. Discard it if the insulator is cracked or chipped.

4.

Measure the plug gap with a feeler gauge. Specifications of the plug gap can be found

5.

Attach the plug washer, thread the plug in by hand to prevent cross-threading.

6.

When mounting a new spark plug, you should screw 1/2 more thread with the wrench after the washer is

compressed. If you are mounting an old one, you should only screw 1/8-1/4 more thread.

CAUTION

The spark plug must be securely tightened. An improperly tightened plug can become very hot and possibly

damage the engine. Never use a spark plug with an improper heat range.

CLEANING

CAUTION

Do not use a water hose or pressure washer to clean the engine. Water can damage the engine or

contaminate the fuel system.

•

Keep your machine clean. Thoroughly clean the machine at the end of each use, paying attention to

stones or mud in and around the tines.

•

Clean the engine regularly with a cloth or brush. Keep the cooling system (blower housing area) clean to

permit proper air circulation which is essential to engine performance and life. Be certain to remove all

dust, dirt and combustible debris from exhaust area.

STORAGE & TRANSPORT

The following steps should be taken to prepare your machine for storage.

STORING THE LAWNMOWER FOR SHORT PERIODS

The lawnmower can be stored for short periods of time (less than 15 days) without performing any storage

maintenance.Before placing the lawnmower into storage always carry out the following:

1.

Allow the engine to fully cool.

2.

Ensure the grass collector is empty.

INSTRUCTION MANUAL

Summary of Contents for 1938323001

Page 28: ...INSTRUCTION MANUAL...

Page 29: ......

Page 30: ...PARTS DIAGRAM WER18HP4 1938323001 INSTRUCTION MANUAL...

Page 32: ...PARTS DIAGRAM WER18HW4 1938324001 INSTRUCTION MANUAL...

Page 33: ...PARTS LIST WER18HW4 198324001...

Page 42: ...Webb Lawnmowers Murdock Road Dorcan Swindon Wiltshire SN3 5HY...