31

CR7

5 Preserving the Machine

5.1 Preservation Measures

If the soil compactor is planned to be put out of operation for an extended period of time (approx. 1 ... 6

months), e. g. during the winter season, it must be stored in a frost-proof and dry room. Before storing the

machine, however, the preservation measures described in paragraph 5.1 must be taken. After the storage,

the soil compactor must be put in operation according to paragraph 5.2.

If the soil compactor is to be stored for more than 6 months, additional measures must be taken in

accordance with your WEBER service.

5.2 Removing Machine Preservatives

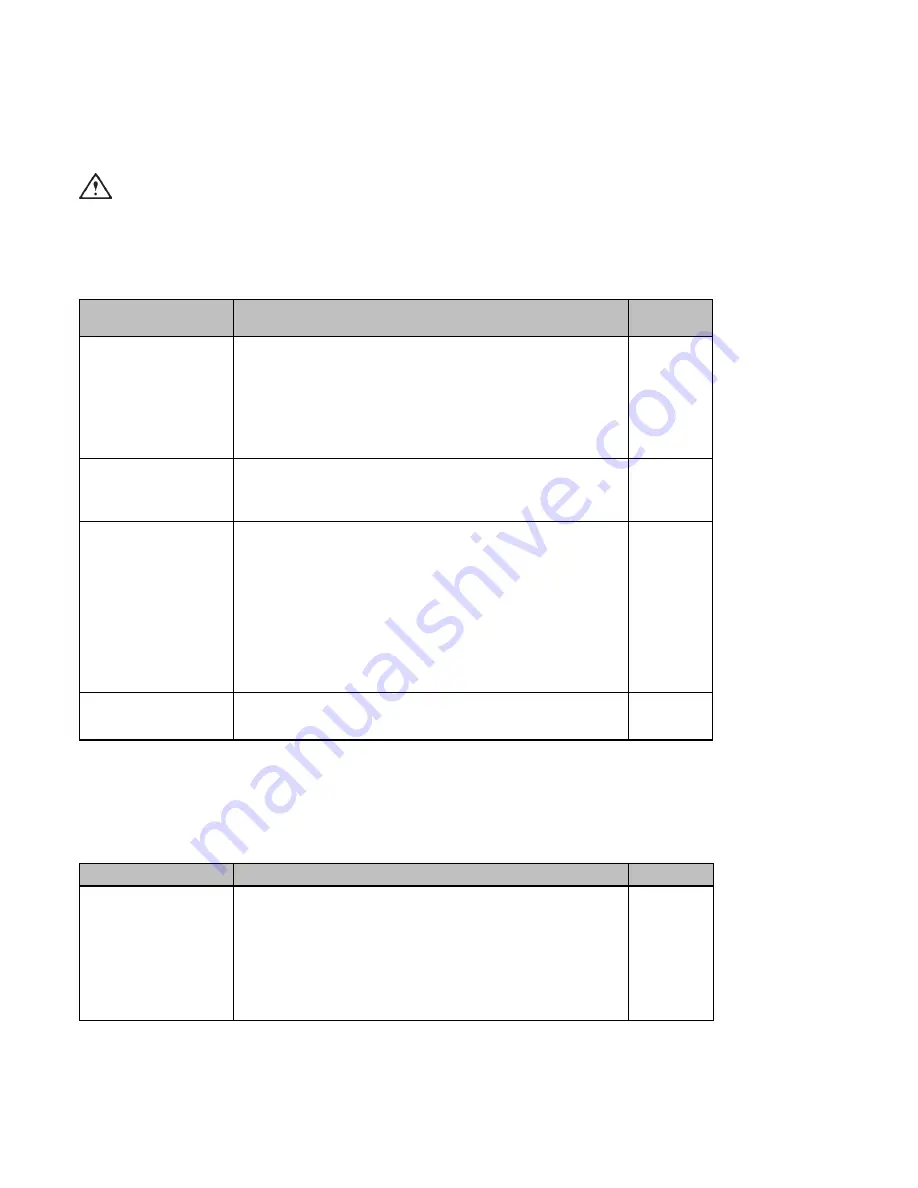

Assembly Group

Measure

Remarks

Whole soil compactor

- Thoroughly clean

- Check condition, fastenings and tightness

- Have any failures ascertained repaired

All bare parts

- Apply a slight film of grease or oil

Fuel tank

- Add fuel up to the bottom edge of the filler neck

# 2.4.1

Engine

- Check the oil level, if required, add oil

# 2.4.2

-

In the location of storage, put the engine into operation until

its operating temperature is achieved.

- Put the engine out of operation

# 2.7

Battery

-

Detach, charge, measure the fluid level, add distilled water if

required

# 4.3.1

Assembly Group

Measure

Remarks

Whole soil compactor

- Thoroughly clean

- Charge the battery

- Perform pre-start work

# 2.4.

Summary of Contents for CR 7

Page 2: ...2 CR7 ...