PG55_110E

15

1

2

1

It is recommended to use a second trowel machine for surfaces with an area

exceeding 200 sqm.

The first machine is then used for pre-troweling with a troweling pan.

The second machine is fitted with troweling blades and used for fine troweling.

Possible applications

The trowel machine can be used for the machine-assisted troweling of concrete surfaces,

e.g. industrial floors, roller skate rinks, parking decks, sewage plants, basement and garage

floors, screed surfaces, etc.

The concrete surface is leveled. During this process, the concrete surface is compacted

due to a thorough rearrangement of the aggregate particles. Any shrinkage cracks and

pores that may have been brought about by escaping air are sealed. Minimum size

particles shift and settle in the cavities between the larger aggregates. The shifted particles

push any retained water to the surface, where it evaporates.

The number of passes required for pre-troweling cannot be specified exactly as this

number is influenced by various factors (e.g. concrete consistency, ambient temperature,

humidity, etc.). Under normal conditions, however, one to two passes will suffice.

The right time for pre-troweling has come when a person

walking on the cured concrete surface no longer leaves

footprints behind.

Pre-troweling involves the process of grinding off any

unevenness caused by pouring the concrete and rubbing

the ground-off material into any cavities and recesses that

may exist in the floor.

Pre-troweling

The surface to be smoothed is pre-troweled with the

troweling pan (1).

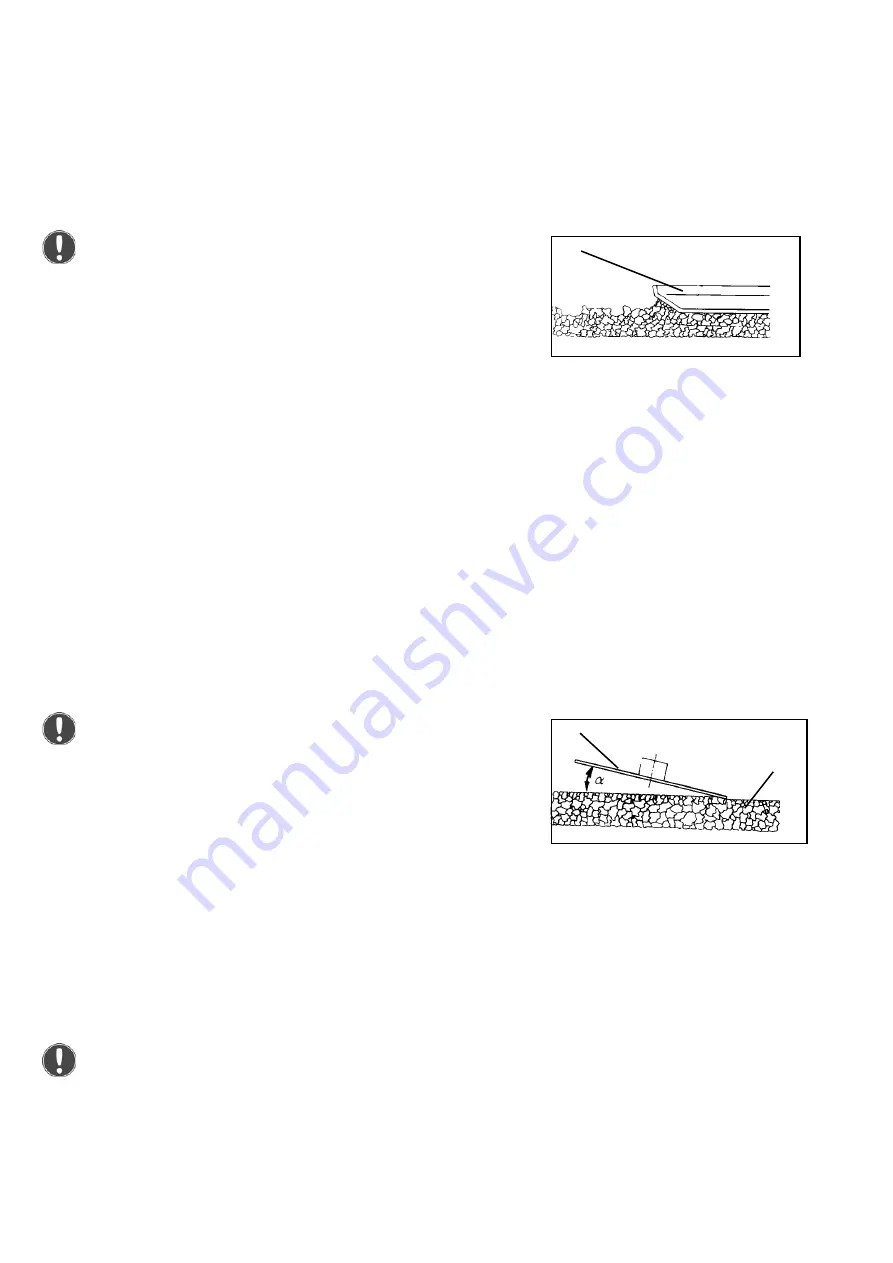

For the first few passes, the blade angle (a) is usually kept small. The blade angle

increases with the number of passes. A key factor during this process is the weight of the

machine. The wider the angle of the troweling blades and the higher the weight of the

machine acting on the troweling blades are, the harder and, thus, more resistant to wear

the surface is.

Fine troweling is applied when no more moisture can be

detected on the surface. For fine troweling the troweling pan

is substituted for the troweling blades.

The troweling blades (1) rotate across the concrete surface (2)

at relatively high pressure and at a certain blade angle (

a

).

Fine troweling requires that the surfaces have been

pre-treated with the troweling pan.

Fine troweling