Chapter 6

Installation and initial startup

32708885 Geset 100

Version: 16.07.13

Page 32 of 77

GB

6. Installation and initial startup

Safety instructions

Danger to life from actively controlled movements

.

RISK OF INJURY FROM CRUSHING!

The movements of the labeling system are motor-driven by an

automatic controller in automatic operation.

- Maintain a distance from moving parts.

Danger of being pulled in by rotating elements.

DANGER OF BEING PULLED IN!

Rotating elements at the labeling machine, backing rewinder, label

feed, *²conveyor belt and *²top conveyor are driven by a motor.

- Do not grip in, at or between the moving parts.

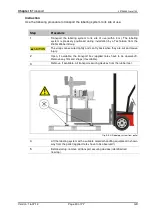

Installation

Continuous operation with minimal wear and downtime can only be ensured when the

system is installed properly. Fine adjustments to the conditions of use are essential when

installing the system. These fine adjustmetns are adapted to the surrounding conditions.

To make these fine adjustments, detailed professional knowledge is necessary that arises

from experience with labeling systems.

This required professional knowledge cannot be completely communicated by the operat-

ing instructions; therefore a Technician from the

Bluhm Weber Group

needs to perform

the installation or accept the labeling system in a final inspection. The warranty does not

cover damage or consequential damage arising from improper installation lacking the

necessary fine adjustments.

Requirements at the installation site

¥

An enclosed and clean room.

¥

Flat, solid base.

¥

Any unevenness may not exceed 5 mm when stands from the Bluhm Weber

Group are used.

¥

Sufficient bearing capacity: 1,500 kg/m².

¥

Low vibration environment.

¥

Sufficient lighting: 500 Lx.

¥

No direct exposure to sunlight or a radiator.

¥

The machine may not be operated within electrostatic or magnetic fields. This

can cause the controls to malfunction.

¥

A proper energy supply (electricity) according to the chapter, "Specifications" on

page 24.

Summary of Contents for Geset 100

Page 2: ...Blank page ...