-18 -

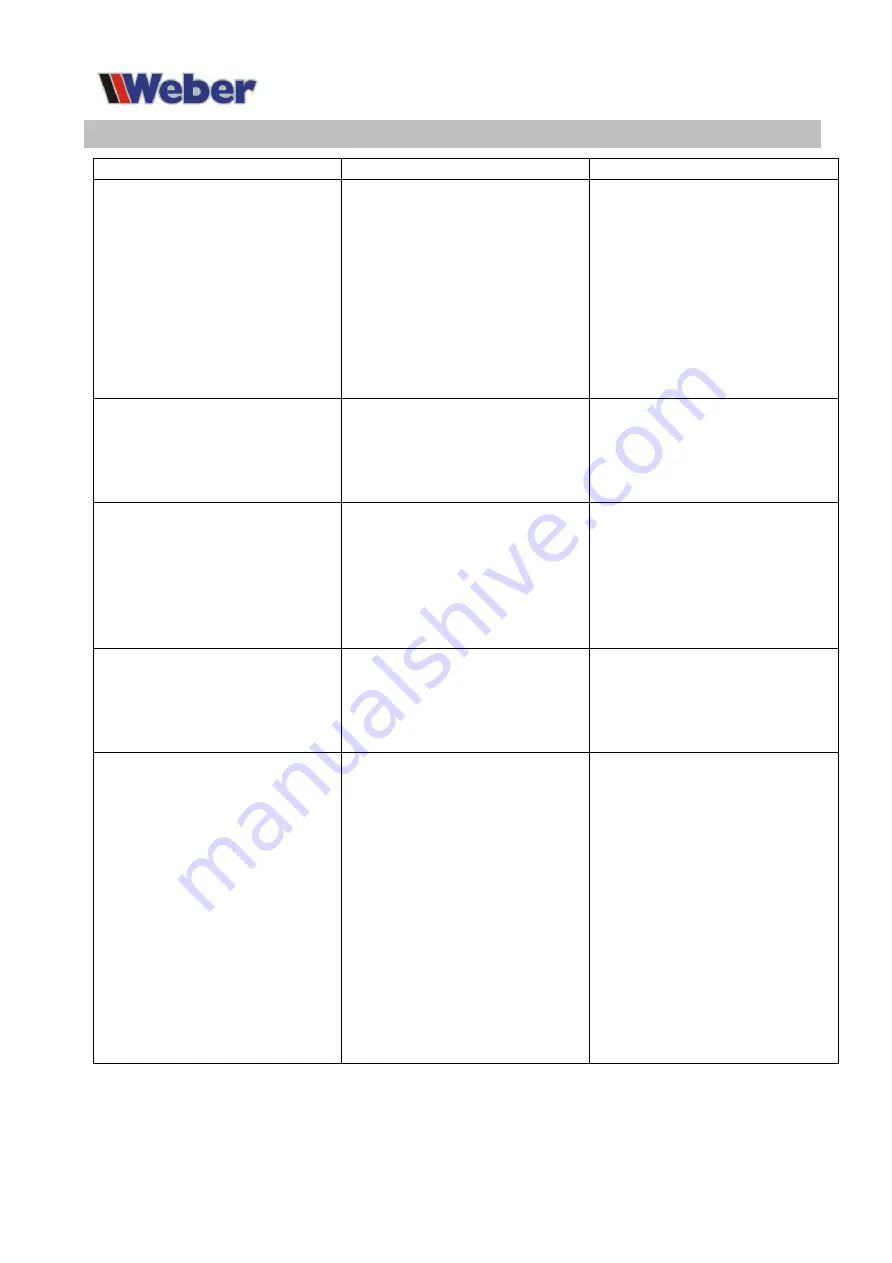

Symptom

Cause

Solution

No signal on the display

after switching on.

1. Power supply failure.

2. The machine power

supply unit is

defective.

3. Incorrect connection

between circuit board

and power supply.

4. Failure of the motherboard.

1. Check the external

power supply.

2. Replace the power supply

unit.

3. Check both the

connection cables and

the plug connectors.

4. Replace the

motherboard.

The buttons "START", "Dis",

"Br" and "Slide" do not

accept input.

1. Plug connectors are loose.

2. Main board defective.

1. Remove the cover from

the machine and check

the internal plug

connection.

2. Replace the motherboard.

The display is fine, but

the brake does not work.

1. loose connection between

motherboard and power

supply.

1. Restore the cable/plug

connection between

motherboard and power

supply.

2. Replace the power supply.

3. Replace the motherboard.

2. Power supply defective.

3. Defective motherboard.

Number of revolutions too

low, brake error, inaccuracy

in balancing.

Drive belt too loose.

Open the machine, tighten

the drive belt. The motor

and drive belt are precisely

matched.

Incorrect balancing values.

1. The machine is set up

unstably.

2. Wheel not tight enough.

3. Power supply in the

machine is defective.

4. Too many voltage

fluctuations in the power

supply.

5. The calibration has

changed.

1. Set and confirm

according to the

instructions.

2. Loosen the wheel and

tighten it again.

3. Check all electrical

connections in the

machine.

4. Security of compliant

energy supply systems.

5. recalibration of the

machine according to

the operating

instructions.

Troubleshooting must be carried out by qualified personnel. If necessary, the instructions

and permission of the after-sales service prior authorization must be requested.

Malfunctions: diagnosis & troubleshooting