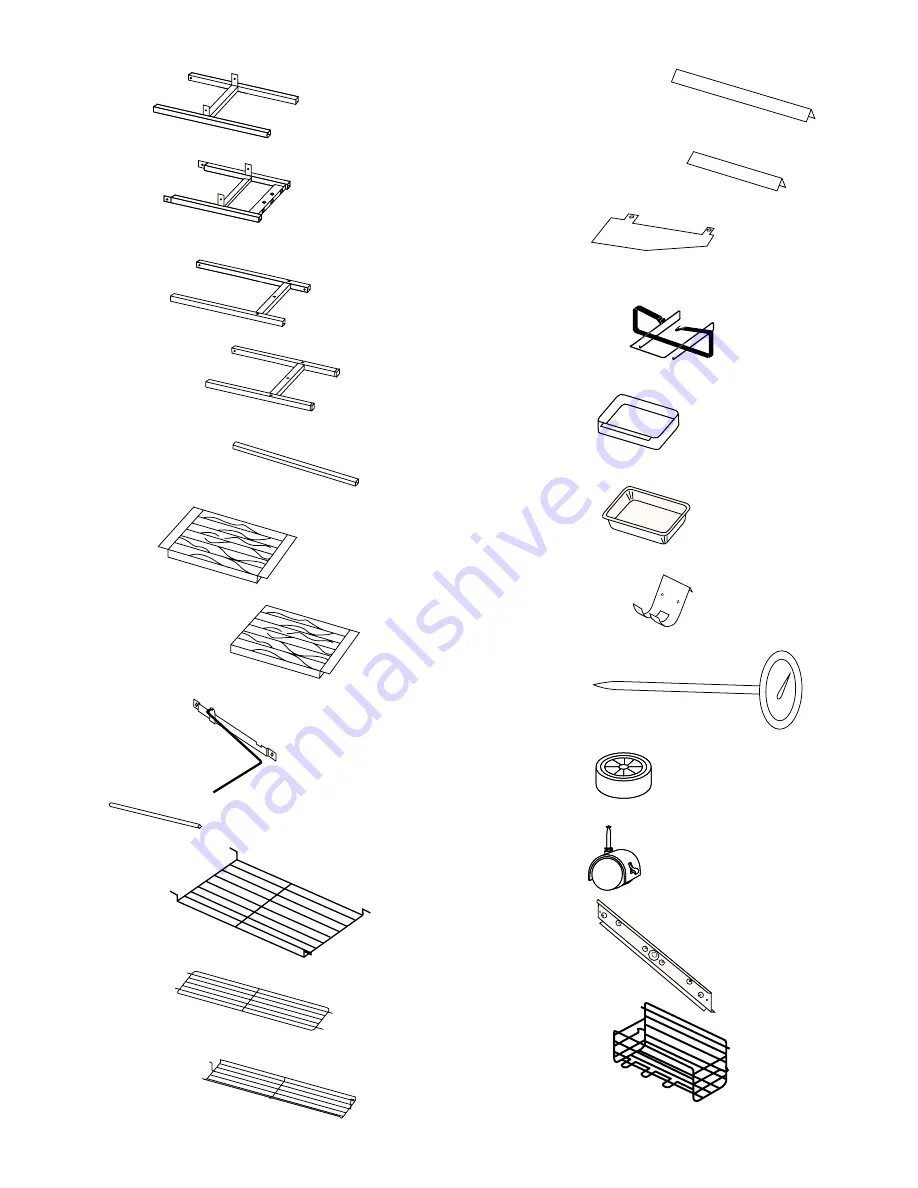

Left frame

Right frame

Wheel frame

Caster frame

Two frame connectors

Work table

Swing table assembly

Left hand slide bar

Axle

Accessory tray

Warming rack

Warm-Up Basket

Five long Flavorizer Bars

Eight short Flavorizer Bars

Front panel

Catch pan holder

Catch pan

Two drip pans

Manifold bracket

Thermometer

Two wheels

Two casters

Spacer bracket

Condiment basket

with tool holders

8

W

EB

E

R

W

EB

E

R

W

EB

E

R

W

EB

E

R