WELD THE WORLD

Cod. 006.0001.1960

03/05/2019 V.2.2

Discovery 172T

31

ENGLISH

-

Q-START

○ This parameter allows the unit to start in synergic pulsed TIG mode for the preset time interval,

before switching automatically to the welding procedure selected on the interface panel. The pa

-

rameter creates the weld pool more quickly than a standard starting time of the material because

it creates a movement of the two flaps up to speed up the join.

○ This parameter is useful when spot welding thin gauge sheet.

Tab. 12 - Recommended Q-START parameters

CORNER/BUTT JOINT

Sheet thickness (mm)

Current (A)

Q start value (seconds)

1.0 mm

35 A - 50 A

0.5 - 1.0

2.0 mm

50 A - 80 A

3.0 mm

80 A - 140 A

4.0 mm

140 A - 170 A

- DYNAMIC ARC

○ This function allows, on the reduction of the arc voltage, an increase of the welding current and

vice versa. The amount of DynamicArc variation can be individually adjusted for a value between

1 A and 50 A. For example, an increase of 50A for a 1 volt variation.

○ This value must be set depending on the material thickness, and the type of processing to be

carried out (values between 1 A and 20 A for thin layers while a value between 20 A and 50 A for

medium-thick layers).

○ Welding power remains constant even when the distance between electrode and workpiece

changes.

-

Consequences of a higher value:

•

The welding arc concentration remains unchanged.

•

Prevents electrode sticking.

•

Increased welding speed.

•

Minor plastic deformity in the welded workpiece.

•

Greater penetration at the apex.

•

Concentrated heat contribution only to the welding and not to the surrounding area.

•

Minor oxidation of the piece and therefore lower post-weld re-work costs.

•

Better control of first application in gaps (useful for pipe fitters and installers).

•

Ease of welding even for pieces which are not properly prepared.

•

Minimization of errors and greater arc stability with motion variations.

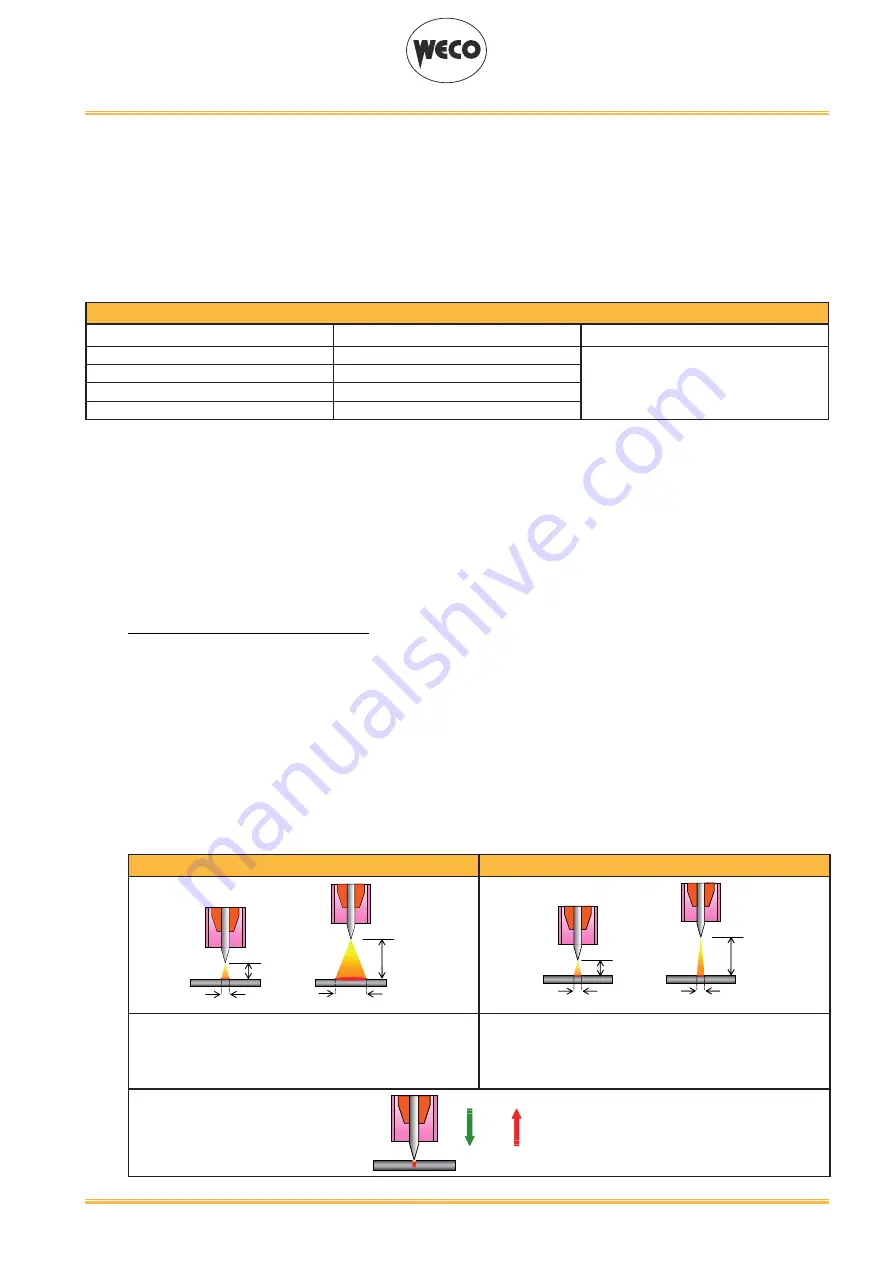

STANDARD TIG DC WELDING

TIG DC WELDING WITH DYNAMIC ARC

D

D

2mm

10mm

D

D

2mm

10mm

In varying the length of the arc, the weld pool (D) widens

with a consequent increase in the heat contribution of

the workpiece, causing it to overheat.

By varying the arc length the weld pool is exactly the

same size (D) while avoiding the overheating of the

piece, plastic deformations and loss of mechanical char

-

acteristics.

Volts

Ampere

Summary of Contents for Discovery 172T

Page 1: ...Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T Instruction manual ENG...

Page 2: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 2 ENGLISH...

Page 50: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 50 ENGLISH 13 WIRING DIAGRAM...

Page 55: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 55 ENGLISH...