WELD THE WORLD

Cod. 006.0001.1960

03/05/2019 V.2.2

Discovery 172T

45

ENGLISH

11 JOBS MANAGEMENT

Personalised welding settings, or JOBs, can be saved in memory locations and subsequently uploaded.

Up to 50 JOBS can be saved (j01-j50).

JOBs can be managed only when the unit is not in welding mode.

The SETUP menu settings cannot be saved by means of the JOBs.

When a JOB is loaded and an UP/DOWN torch is installed, press the torch triggers to select the saved

JOBS.

If there are no JOBS loaded, the UP/DOWN buttons on the torch serve to adjust the welding current.

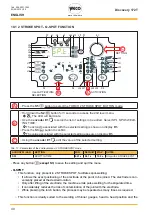

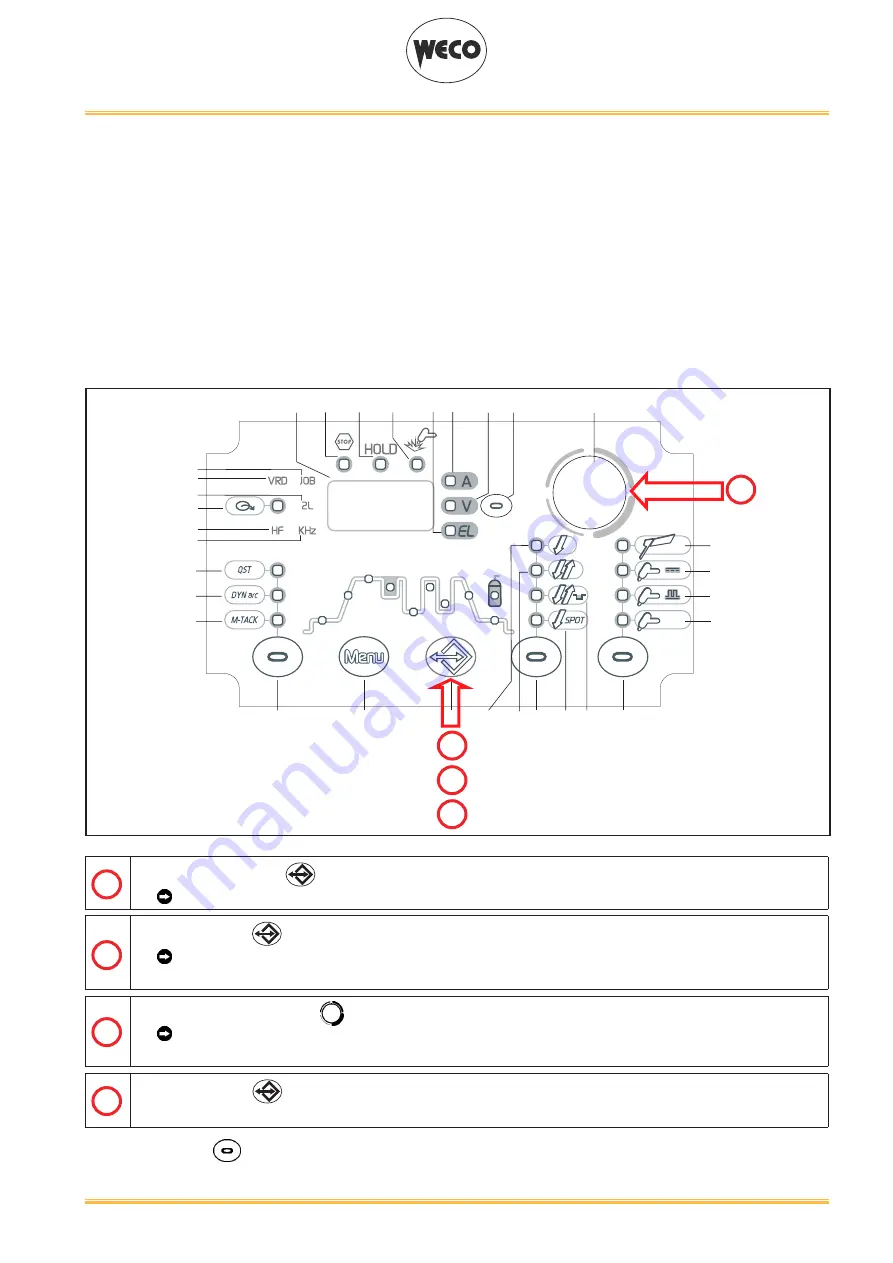

11.1 SAVING A JOB

SYN

L1

L2

L3

L15

L13

L14

L10 L11

L12

L29 L28

D1

S1

S2

E1

L6

S3

S4

S5

S6

L9

L8

L4

L5

L7

L33

L31

L32

L30

L26 L27

L18

L22

L20

L21

L23

L24

L25

L17

L16

L19

A

B

D

C

3sec ACTIVATION

CONFIRMATION

SAVING

SA.

SELECTION

A

○ Hold down the

S4

button for 3 seconds to gain access to the JOB SAVE/DELETE menu.

SA.

: The message appears on the following displays

D1

.

B

○

Press the

S4

button to confirm.

S.xx

: The message will appear on display

D1.

•

xx= number of the first free job.

C

○

Using the

encoder E1

, select the desired job number.

S.yy

: The message will appear on display

D1.

○ On selecting a currently occupied memory location, the job number flashes.

D

○

Press the

S4

button to save the JOB and exit the menu. If you confirm at this point, the

new job will overwrite the previously saved settings.

Press any button

(

except S4

) to exit without confirming.

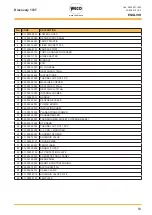

Summary of Contents for Discovery 172T

Page 1: ...Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T Instruction manual ENG...

Page 2: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 2 ENGLISH...

Page 50: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 50 ENGLISH 13 WIRING DIAGRAM...

Page 55: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 55 ENGLISH...