7

If you find that a significant adjustment was required to make the two crossbars

parallel then you should remember which stand goes at each end of the anchoring rails

to maintain the bolt adjustment you have made for future anchoring setups. In any

event, it is useful to check that the crossbars are parallel by sighting along the bars

after completing each anchoring setup on the vehicle. Re-adjust the bolts on the

stands to make the crossbars parallel if necessary.

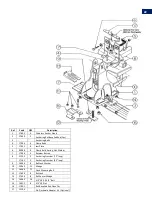

1.

Install the front pinchweld clamps:

a)

Center vehicle between the left and right anchoring rails.

b)

Raise the front end of the car and place the safety stands underneath.

c)

Check for strongest location on the pinchweld to secure the pinchweld clamp (for

the forward clamp this is usually the extreme forward location on the

pinchweld.) Do not clamp onto fuel or brake lines and other obstructions along

the pinchweld area. NOTE: If the vehicle does not have pinchweld flanges see

“Anchoring Vehicles With No Pinchweld and No Frame”, on Page 19.

d)

Make sure clamps are bottomed out evenly on the pinchweld flange from one

side to the other.

The top of the pinchweld clamp should be placed up against the bottom of the sill

(rocker) panel. On some vehicles this may not be possible. In these cases be certain that

the clamps are up as high as possible and are level with the bottom of the sill (rocker)

panel. It is important that the clamps are positioned at the same height on both sides

of the car.