Parts & Service 21/09/2015

902-002-11 Rev 6

Page 11

SECTION 3:

Maintenance

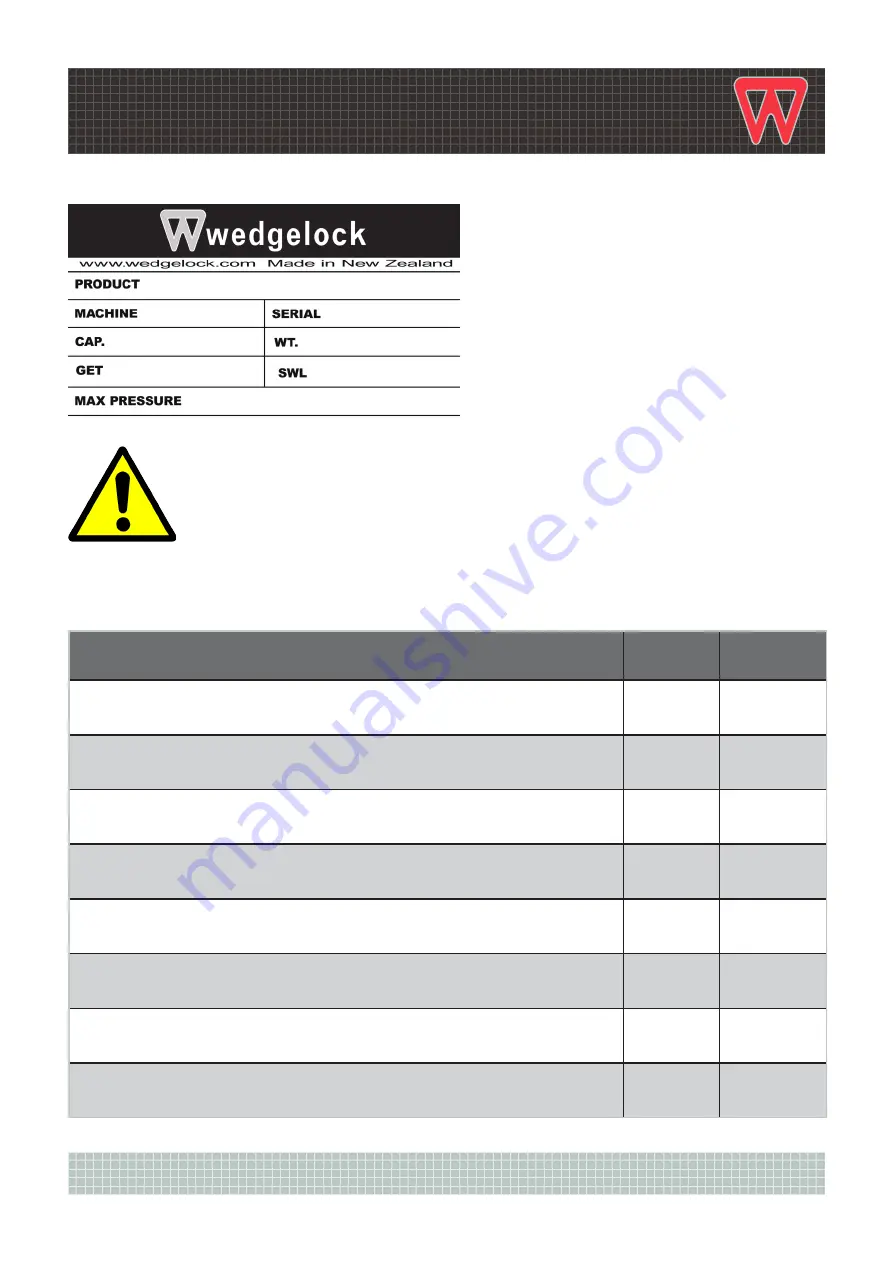

3.0 COUPLER IDENTIFICATION

All Wedgelock Couplers are fitted with an Aluminium

Data Plate (FIG 3.0.1). Information pertains to the

product code, the carrier machine, product serial

number, working load limit (for lifting purposes) and

the maximum operating pressure. If any of the cells

are left blank it means that the information is non

applicable to this attachment

WARNING: Wedgelock Quick Couplers that incorporate a factory fitted lifting eye will be labeled

and marked with a Working Load Limit (WLL) of the lifting eye. The lifting eyes are designed in

accordance with NZS/BS2573:Part1. It is highly recommended that a Bow Type Shackle be used to

connect to the lifting eye. See page 15.

3.1 SERVICING SCHEDULE

Maintenance Required

Daily

Weekly

Check all pin retainers, bolts & nuts for tightness on the quick coupler and

the attachments

ü

Lubricate all greasing points – the attachment will have to be removed to

access all grease points.

ü

Check hydraulic hoses and fittings for any leaks or wear – replace

immediately if required

ü

Check the quick coupler switch and audible warning buzzer is operating

properly

ü

Check the full operation of all the moving parts within the quick coupler –

repair or replace immediately if required

ü

Check the hydraulic cylinder mounting bolts for tightness – remedy if

required

ü

Thoroughly clean the quick coupler and ensure there is no material build up

around locking cylinder, wedge or I-Lock™ safety system

ü

Check the quick coupler for evidence of fatigue, weld failure or stress – if

evident contact your Wedgelock dealer immediately for assistance

ü

Fig. 3.0.1

EXAMPLE