Parts & Service 21/09/2015

902-002-11 Rev 6

Page 13

SECTION 4:

Troubleshooting

4.0 TROUBLE SHOOTING GUIDE (cont.)

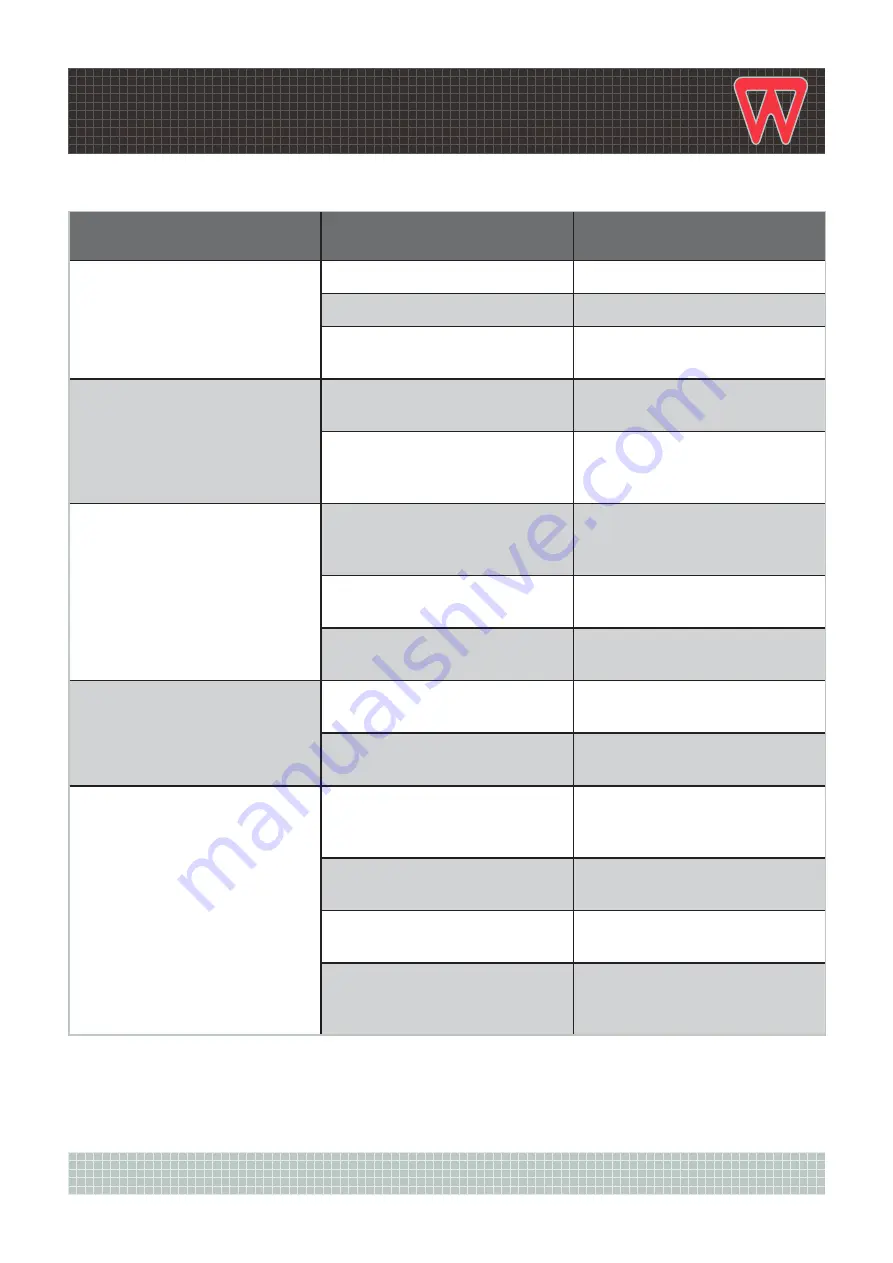

PROBLEM

CHECK

REMEDY

3. The I-Lock Safety Knuckle is slow

to or partially activates. (cont.)

Check for damage to Safety Knuckle

Replace parts if required

Check grease around I-Lock piston

Grease liberally

Check I-Lock spring assembly for

damage

Replace if required

4. There is oil leaking around the

I-Lock piston assembly

Check the hose connection on the

I-Lock piston

Tighten as necessary

Check seals, rod and bore of piston

assembly for damage

Remove the I-Lock piston assembly

and dismantle. Replace parts where

necessary and re-assemble.

5. The primary wedge is operating

slower than normal

Check that the operator is crowding

the bucket cylinder to create machine

pressure

Crowd the bucket cylinder to

overcome low idle pressure

Check the operating pressure that

extends the Primary Wedge

Adjust the pressure reducing valve if

required

Check the inlet port on coupler

directional control valve

Clean and clear any debris that is

present from the orifice

6. There is oil leaking around the

main cylinder in the coupler

Check hoses and connections to the

main cylinder

Tighten and replace as necessary

Check cylinder for damage

Remove main cylinder and dismantle.

Replace any damaged parts

7. Primary Wedge will not retract

Check coupler for any debris that

maybe lodged behind the Wedge

plate

Clear the debris

Inspect the Pilot Operated Safety

Check valve in main cylinder

Remove, clean and replace if

necessary

Check in-cab I-Lock Lock-Out switch

is functioning

See previous instructions

Check mechanical function of

solenoid spool valve for the Primary

Wedge circuit

Remove spool valve, clean and

clear any debris. Replace spool if

necessary