7

NORTH AMERICA

Page 6

SECTION 3: COUPLER INSTALLATION

3.0 SAFETY DURING COUPLER INSTALLATION

• Always use the correct PPE when removing attachments from carrier machines.

Stand well clear of machinery that is in motion at all times.

NEVER place hands or fingers near pin holes or recesses.

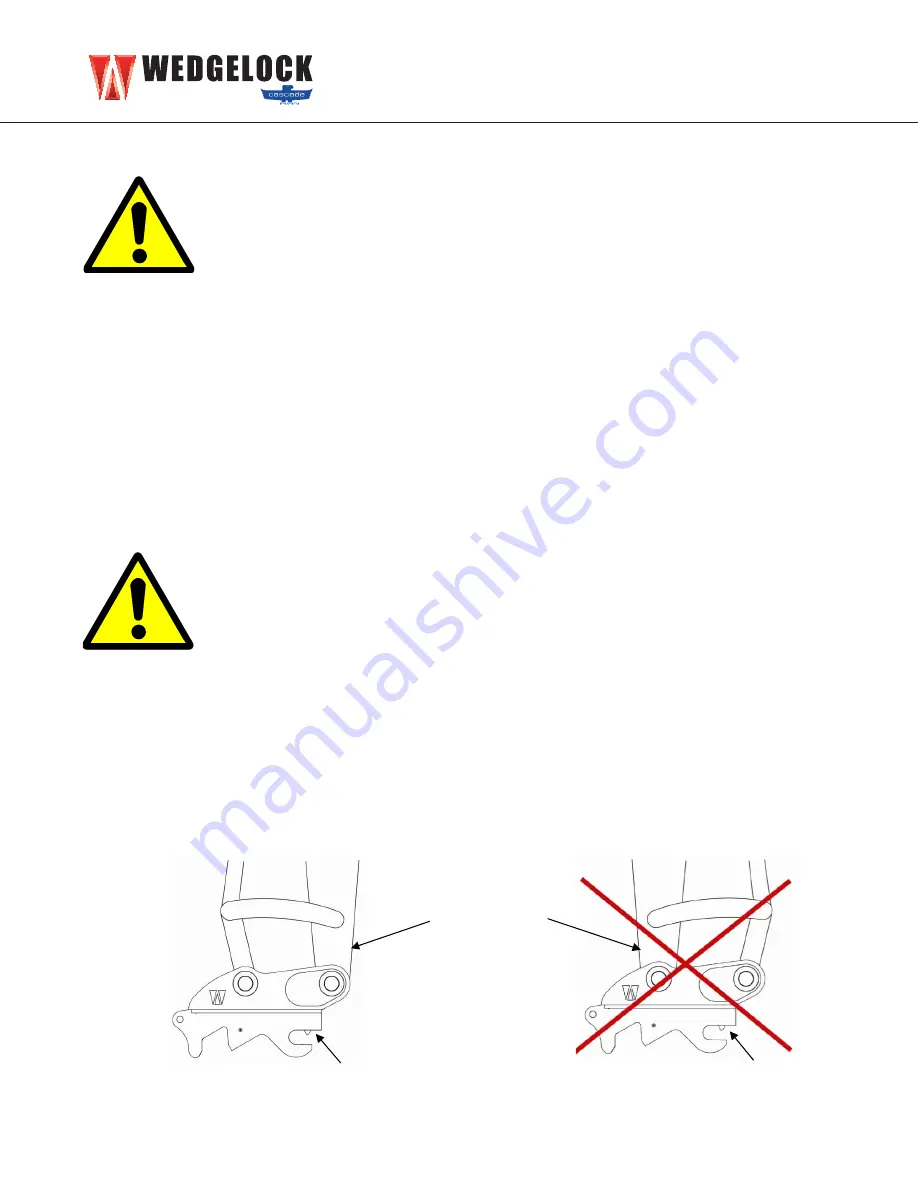

The I-Lock Coupler has been designed and manufactured to fit the dipper arm and

linkage assembly of the carrier machine. The I-Lock Coupler fits the carrier

machine in one orientation only with the C-Section facing the operators view

(see fig 3.0.1)

Always use the original bucket pins to fit the coupler the machine. These pins are designed for the

dipper arm and linkage assemblies.

Always replace o’rings to original positions and utilize pin retention systems where applicable.

DO NOT

use standard attachment pins to connect the coupler to the machine. If unsure consult

your Wedgelock Dealer immediately.

If a

THUMB

is / will be fitted to the carrier machine utilizing the main dipper pin position refer to the

THUMB Installation Guide for reference.

3.1 COUPLER ORIENTATION

Always use correct tools when carrying out removal and installation of attachments on the carrier

machine.

Use correct lifting techniques and lifting equipment when maneuvering heavy objects

Attachments may roll or tip during removal when placed on the ground – place with extreme

caution

Always use assistance when installing and removing attachments pinned to the carrier machine

Dipper Arm

(Operator View)

Coupler C-Section

Coupler C-Section

FIG 3.1.1 Coupler Orientation

Fig 3.1.1 Coupler Orientation

NORTH AMERICA

SECTION 1: SAFETY

3.0 SAFETY DURING COUPLER INSTALLATION

•

Always use the correct PPE when removing attachments from carrier machines.

•

Stand well clear of machinery that is in motion at all times.

• NEVER place hands or fingers near pin holes or recesses.

•

Always use correct tools when carrying out removal and installation of attachments on the carrier

machine.

• Use correct lifting techniques and lifting equipment when maneuvering heavy objects.

• Attachments may roll or tip during removal when placed on the ground – place with extreme

caution.

•

Always use assistance when installing and removing attachments pinned to the carrier machine.

3.1 COUPLER ORIENTATION

The I-Lock Coupler has been designed and manufactured to fit the dipper arm

and linkage assembly of the carrier machine. The I-Lock Coupler fits the carrier

machine in one orientation only with the C-Section facing the operators view.

(see fig 3.0.1)

• Always use the original bucket pins to fit the coupler to the machine. These pins are designed for

the dipper arm and linkage assemblies.

•

Always replace o-rings to original positions and utilize pin retention systems where applicable.

•

DO NOT

use standard attachment pins to connect the coupler to the machine. If unsure consult

your Wedgelock Dealer immediately.

•

If a

THUMB

is / will be fitted to the carrier machine utilizing the main dipper pin position refer to

the THUMB Installation Guide for reference.

Fig 3.1.1 Coupler Orientation