9

NORTH AMERICA

SECTION 3: COUPLER INSTALLATION

3.4 FITTING THE COUPLER (Dipper Pin)

• Place o-rings over ear plates of coupler to hold in position until ready for final placement.

•

Carefully raise the dipper arm of the carrier machine so that the weight of the coupler is off the

ground. Ensure that the dipper arm is in a vertical position. (Fig 3.4.1).

•

Retract the bucket curl cylinder until the coupler front boss aligns with the dipper pin hole. The

coupler will balance allowing an easy insertion of the main dipper pin.

• Align pin retention system and fix dipper pin into place.

•

Grease both the dipper pin and the linkage pin.

•

Rotate coupler through full rotation to check clearances.

•

NOTE – ORIGINAL OEM DIPPER PIN MUST BE USED.

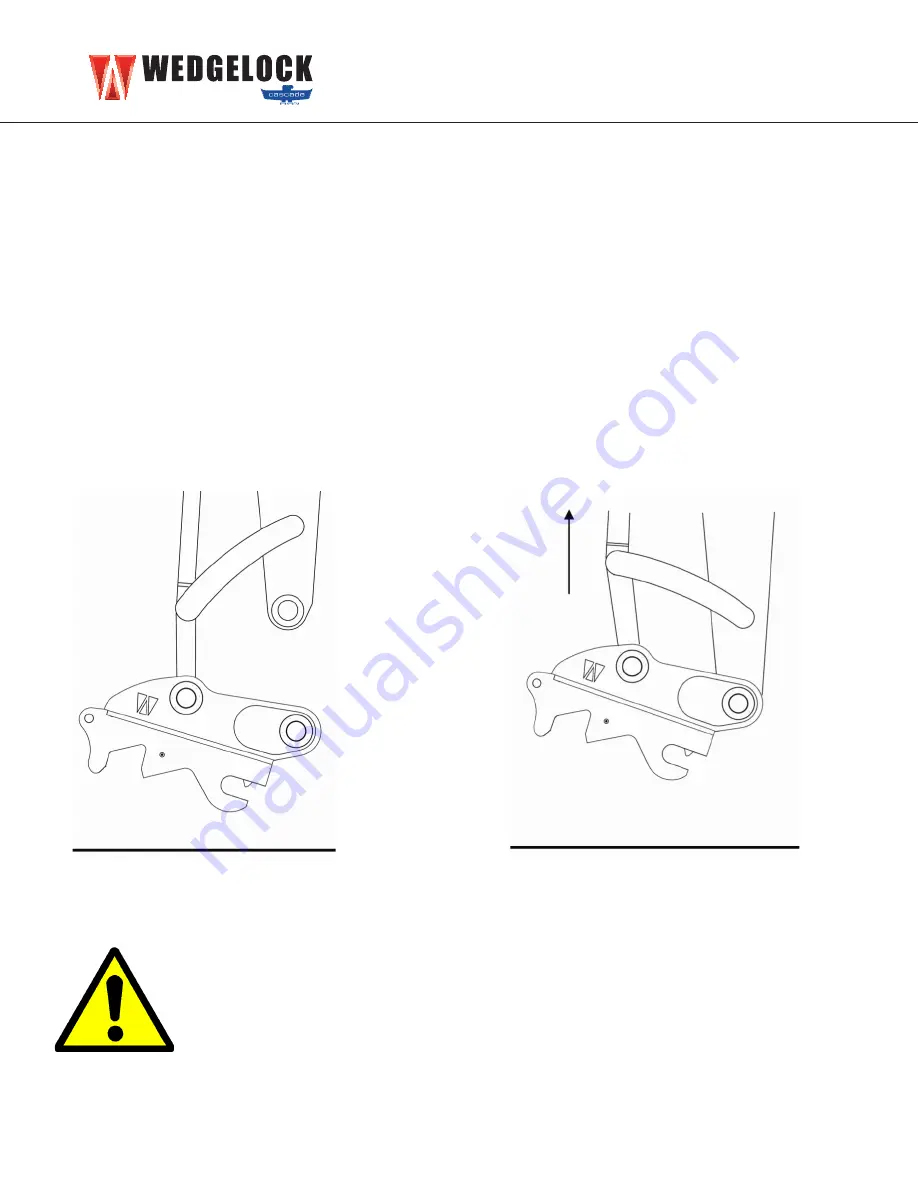

Fig 3.4.1 Raise dipper arm to

take weight off coupler

Fig 3.4.2 Retract bucket curl cylinder

to align dipper pin

CAREFULLY ROTATE THE COUPLER THROUGH FULL ROTATION TO

CHECK CLEARANCES

IF THERE ARE ANY SIGNS OF INTERFERENCE STOP IMMEDIATELY AND

CONTACT YOUR WEDGELOCK DEALER

Page 8

SECTION 3: COUPLER INSTALLATION

3.4 FITTING THE COUPLER (Dipper Pin)

Place o’rings over ear plates of coupler to hold in position until ready for final placement.

Carefully raise the dipper arm of the carrier machine so that the weight of the coupler is off the

ground. Ensure that the dipper arm is in a vertical position. (Fig 3.4.1).

Retract the crowd cylinder until the coupler front boss aligns with the dipper pin hole. The coupler

will balance allowing an easy insertion of the main dipper pin.

Align pin retention system and fix dipper pin into place.

Grease both the dipper pin and the linkage pin.

Crowd coupler through full rotation to check clearances.

NOTE – ORIGINAL OEM DIPPER PIN MUST BE USED.

Fig 3.4.1 Raise dipper arm to

take weight off coupler

Fig 3.4.2 Retract crowd cylinder

to align dipper pin

CAREFULLY CROWD THE COUPLER THROUGH FULL ROTATION TO CHECK

CLEARANCES

IF THERE ARE ANY SIGNS OF INTERFERENCE STOP IMMEDIATELY AND

CONTACT YOUR WEDGELOCK DEALER

NORTH AMERICA