1160

1160

714

15

6

717

6

15

13

13

13

26

3

13

26

33

32

33

32

13

26

13

13

3

13

26

68

70

70

70

70

17

20

17

20

52

52

3

13

26

3

13

26

33

32

13

1

13

66

12

12

32

13

13

26

13

3

1

26

13

3

715

716

33

109

109

717

34

34

4

114

34

64

714

114

4

34

`çãéäÉíÉ=háí==^`qolp=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêçìéë

80-e.DOC / K-Actros

Page 9

NO

oÉ~ê=~ñäÉ=ëÉÅíáçå=

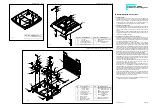

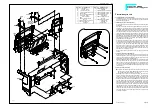

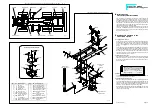

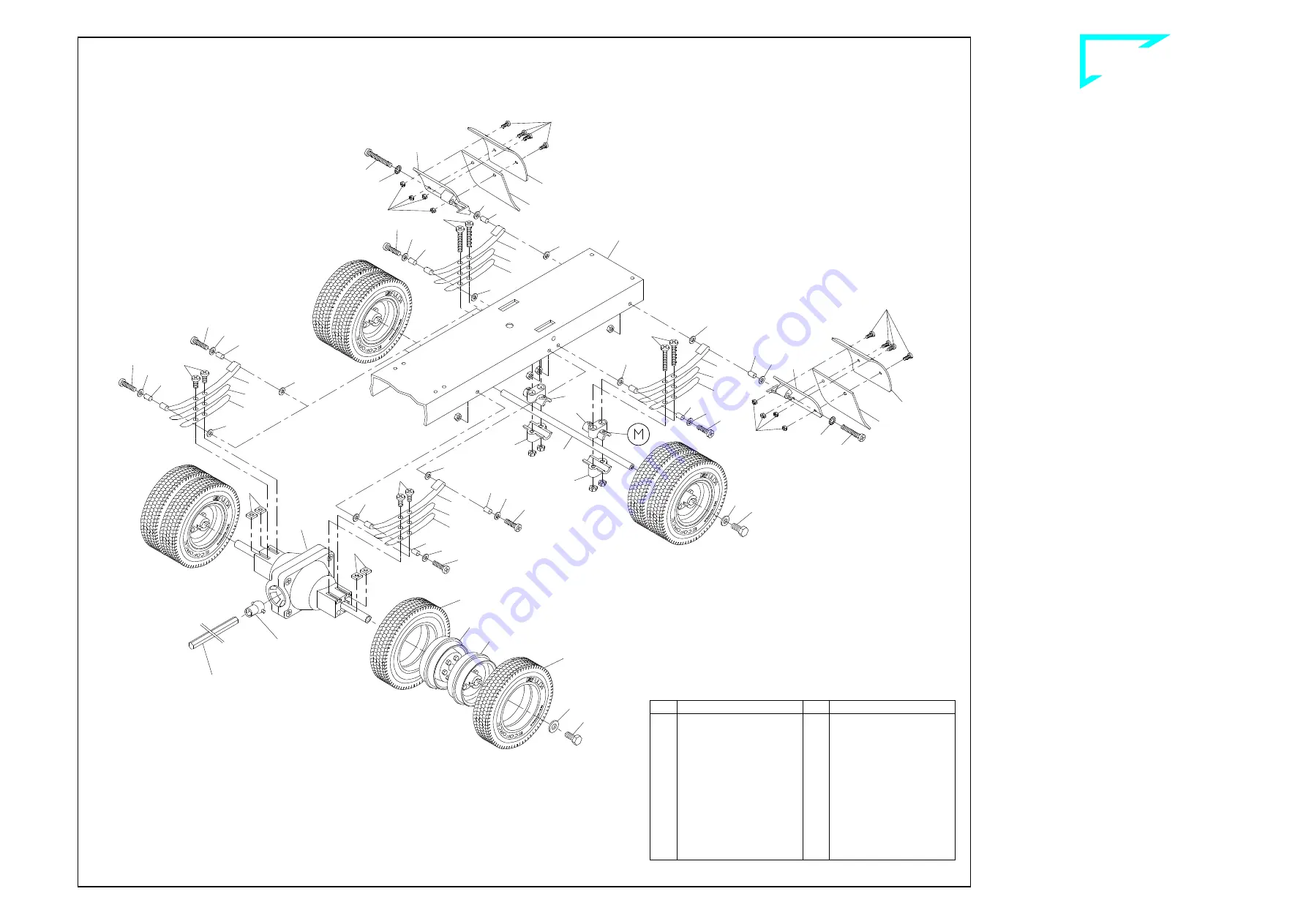

12.1 Mounting the mud guards

The mud guard support 715 is marked with an "X" and will later be

mounted on the passenger’s side, the mud guard support 716

marked "O" on the driver's side. First attach to these supports the

mud flaps 717 and the mud guards 714 with four screws 114 and

nuts 109 each. Then use screws 6, serrated washers 15, bushings

26, two washers 13 and M3 nuts to attach the supports to the holes

at the rear of the frame.

12.2 Mounting the spring set and axle

Attach the open ends of the two long spring leaves 32 to the bushing

and use a screw 3, bushing 26, washer 13 and M3 nut to screw the

closed end to the frame. Press one each M3 nut into the hexagonal

recess at the lower spring carrier 70. The axle 68 can now be

mounted together with the spring carriers, one medium spring leaf 33

each, a short spring leaf 34 and screws 4.

Ensure that the end of the spring carrier 70 identified with an "M"

is toward the wheel.

The ribbon cable with the two lamp PCBs should be mounted

when attaching the rear axle and the differential!

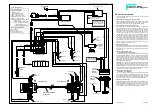

12.3 Mounting the spring set and differential

First attach the long spring leaves 32 to the frame. Once you have

inserted one square nut 12 each into the grooves at the side of the

differential the springs can be attached with screws 1. The differential

has two cams on the wheel mounts; the grooves in the hubs are

aligned exactly with these cams. The wheels are affixed using

screws 17 (which will cut their own threads) and washers 20. Press

the joint ball 64 into the joint socket at the mounted differential.

In no case should you use an M3 screw more than 6 mm long to

affix the spring set as this would cause binding and damage the

shafts on the differential!

12.4 Mounting the wheels

Once you have mounted the drive axle tyre 1160 on the rims 52 the

wheels are mounted on the shaft, with the wheel nuts facing one an-

other and the chromed rims toward the outside; secure with a washer

20 and a screw 17. The wheels should turn easily but there should

not be too much play.

Rear axle section ill. 12

Qty.

No. Assembly part

12

--- Nut M3

4

1 Screw M3 x 6

6

3 Screw M3 x 12

4

4 Screw M3 x 16

2

6 Screw M3 x 25

4

12 Square nut M3

16

13 Washer 3.2

2

15 Serrated washer 3.2

4

17 Hex head screw M4 x 8

4

20 Washer 4.3

8

26 Bushing 4 x 0.5 x 7

4

32 Spring long, “AF“

4

33 Spring medium, “AF“

4

34 Spring short, “AF“

Qty.

No. Assembly part

4

52 Rim, grey

4

52 Rim, chromed

1

64 Ball joint

1

66 Standard differential,

mounted

1

68 Rear axle 144mm

4

70 Spring carrier, plastic

8

109 Nut M2

8

114 Screw M2 x 6

2

714 Mud guard

1

715 Mudguard support “X“

1

716 Mudguard support “O“

2

717 Mud flap

8

1160 Drive axle tyre “Ecoforce“

Drive shaft

Frame

B-44-10

(grey)

(chromed)

For a better overview the

illustration is showing

an assembly without rear

bumper and fifth-wheel