12

OPERATION

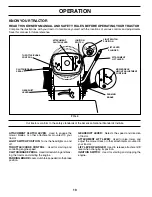

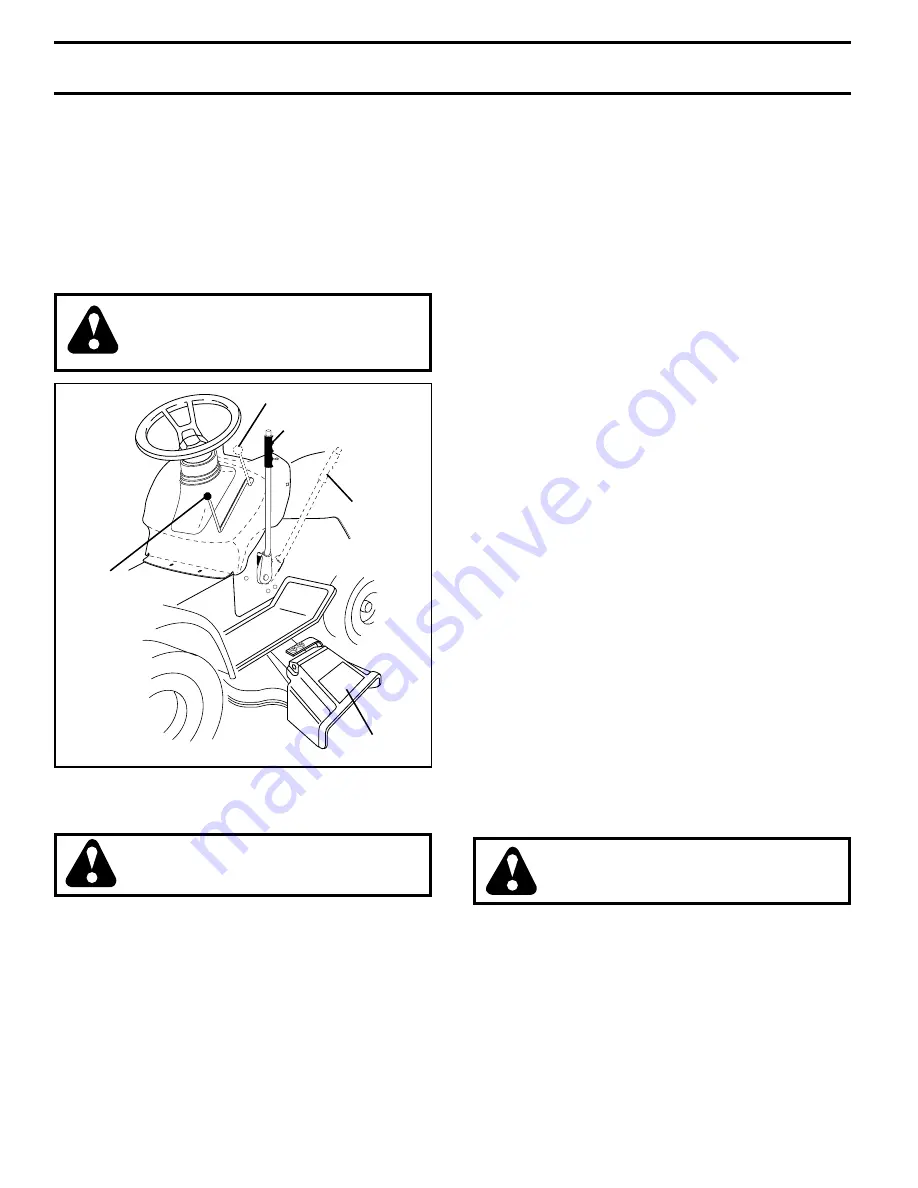

TO OPERATE MOWER (See Fig. 6)

Your tractor is equipped with an operator presence sens ing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

• Select desired height of cut.

• Start mower blades by engaging attachment clutch

control.

• TO STOP MOWER BLADES - disengage attachment

clutch con trol.

CAUTION: Do not operate the mower

without either the en tire grass catcher,

on mowers so equipped, or the defl ector

shield in place.

TO OPERATE ON HILLS

WARNING: Do not drive up or down

hills with slopes great er than 15° and

do not drive across any slope.

• Choose the slowest speed before starting up or down

hills.

• Avoid stopping or changing speed on hills.

• If slowing is necessary, move throttle control lever to

slower position.

• If stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move gearshift lever to 1st gear. Be sure you have

allowed room for tractor to roll slightly as you restart

movement.

• To restart movement, slowly release parking brake and

clutch/brake pedal.

• Make all turns slowly.

FIG. 6

LOW

POSITION

ATTACHMENT LIFT LE-

VER HIGH PO SI TION

"ENGAGED" POSITION

DE FLEC TOR

SHIELD

TOWING CARTS AND OTHER AT

TACH -

MENTS

Tow only the attachments that are recommended by and

comply with specifi cations of the manufacturer of your trac-

tor. Use common sense when towing. Too heavy of a load,

while on a slope, is dangerous. Tires can lose traction with

the ground and cause you to lose control of your tractor.

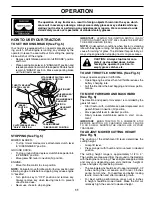

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

• The engine in your tractor has been shipped, from the

factory, already fi lled with sum mer weight oil.

• Check engine oil with tractor on level ground.

• Remove oil fi ll cap/dipstick and wipe clean, reinsert the

dipstick and screw cap tight, wait for a few seconds,

remove and read oil level. If necessary, add oil until

“FULL” mark on dipstick is reached. Do not overfi ll.

• For cold weather operation you should change oil for

easier starting (See “OIL VISCOSITY CHART” in the

Maintenance sec tion of this manual).

• To change engine oil, see the Maintenance section in

this manual.

TO TRANSPORT

• Raise attachment lift to highest position with at tach ment

lift control.

• When pushing or towing your tractor, be sure gearshift

lever is in neutral (N) position.

• Do not push or tow tractor at more than fi ve (5) MPH.

NOTE

: To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc.).

ADD GASOLINE

• Fill fuel tank to bottom of fi ller neck. Do not overfi ll.

Use fresh, clean, regular un lead ed gasoline with a

minimum of 87 octane. (Use of leaded gasoline will

increase carbon and lead oxide deposits and reduce

valve life). Do not mix oil with gasoline. Purchase fuel

in quan ti ties that can be used within 30 days to assure

fuel fresh ness.

CAUTION: Wipe off any spilled oil or

fuel. Do not store, spill or use gasoline

near an open fl ame.

IMPORTANT:

WHEN OPERATING IN TEMPERATURES

BELOW32°F(0°C), USE FRESH, CLEAN WINTER GRADE

GAS O LINE TO HELP INSURE GOOD COLD WEATHER

START ING.

AT TACH MENT

CLUTCH LEVER

"DISENGAGED"

PO SI TION

Summary of Contents for 184404

Page 44: ...44 SERVICE NOTES...

Page 48: ...01029 weedeater...