13

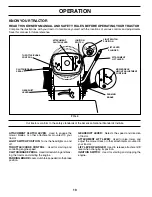

OPERATION

MOWING TIPS

• Tire chains cannot be used when the mower hous ing

is attached to tractor.

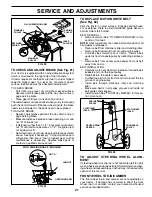

• Mower should be properly leveled for best mowing per-

for mance. See “TO LEVEL MOWER HOUSING” in the

Service and Adjustments section of this manual.

• The left hand side of mower should be used for trim-

ming.

• Drive so that clippings are discharged onto the area

that has been cut. Have the cut area to the right of the

machine. This will result in a more even dis tri bu tion of

clippings and more uniform cutting.

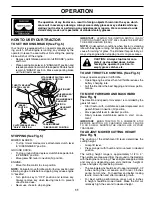

• When mowing large areas, start by turning to the right so

that clippings will discharge away from shrubs, fences,

drive ways, etc. After one or two rounds, mow in the

opposite direction making left hand turns until fi nished

(See Fig. 7 ).

FIG. 7

TO START ENGINE (See Fig. 5)

When starting the engine for the fi rst time or if the engine

has run out of fuel, it will take extra cranking time to move

fuel from the tank to the engine.

• Sit on seat in operating position, depress clutch/brake

pedal and set parking brake.

• Place gear shift lever in neutral (N) position.

• Move attachment clutch to “DISENGAGED” position.

• Move throttle control to choke position.

NOTE:

Before starting, read the warm and cold starting

procedures below.

• Insert key into ignition and turn key clockwise to “START”

position and release key as soon as engine starts.

Do not run starter continuously for more than fi fteen

sec onds per minute. If the engine does not start after

several attempts, move throttle control to fast position,

wait a few minutes and try again. If engine still does

not start, move the throttle control back to the choke

position and retry.

WARM WEATHER STARTING (50° F and above)

• When engine starts, move the throttle control to the

fast position.

• The attachments and ground drive can now be used. If

the engine does not accept the load, restart the engine

and allow it to warm up for one minute using the choke

as described above.

COLD WEATHER STARTING ( 50° F and below)

• When engine starts, allow engine to run with the

throttle control in the choke position until the engine

runs roughly, then move throttle control to fast posi-

tion. This may require an engine warm-up period from

several seconds to several minutes, depending on the

tem per a ture.

• The attachments can also be used during the engine

warm-up period.

NOTE:

If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR” in the Service and Adjustments

section of this manual.

• If grass is extremely tall, it should be mowed twice to

reduce load and possible fi re hazard from dried clip-

pings. Make fi rst cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

•

Always operate engine at full throttle when mow-

ing

to assure better mowing performance and proper

dis charge of ma te ri al. Regulate ground speed by se-

lect ing a low enough gear to give the mower cut ting

per for mance as well as the quality of cut desired.

• When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the at tach ment being used.

CAUTION:

Alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract moisture which

leads to sep a ra tion and for ma tion of acids during stor-

age. Acidic gas can damage the fuel system of an engine

while in storage. To avoid engine problems, the fuel

sys tem should be emptied before stor age of 30 days

or longer. Drain the gas tank, start the engine and let

it run until the fuel lines and carburetor are empty. Use

fresh fuel next season. See Storage In struc tions for

additional information. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage

may occur.

Summary of Contents for 184404

Page 44: ...44 SERVICE NOTES...

Page 48: ...01029 weedeater...