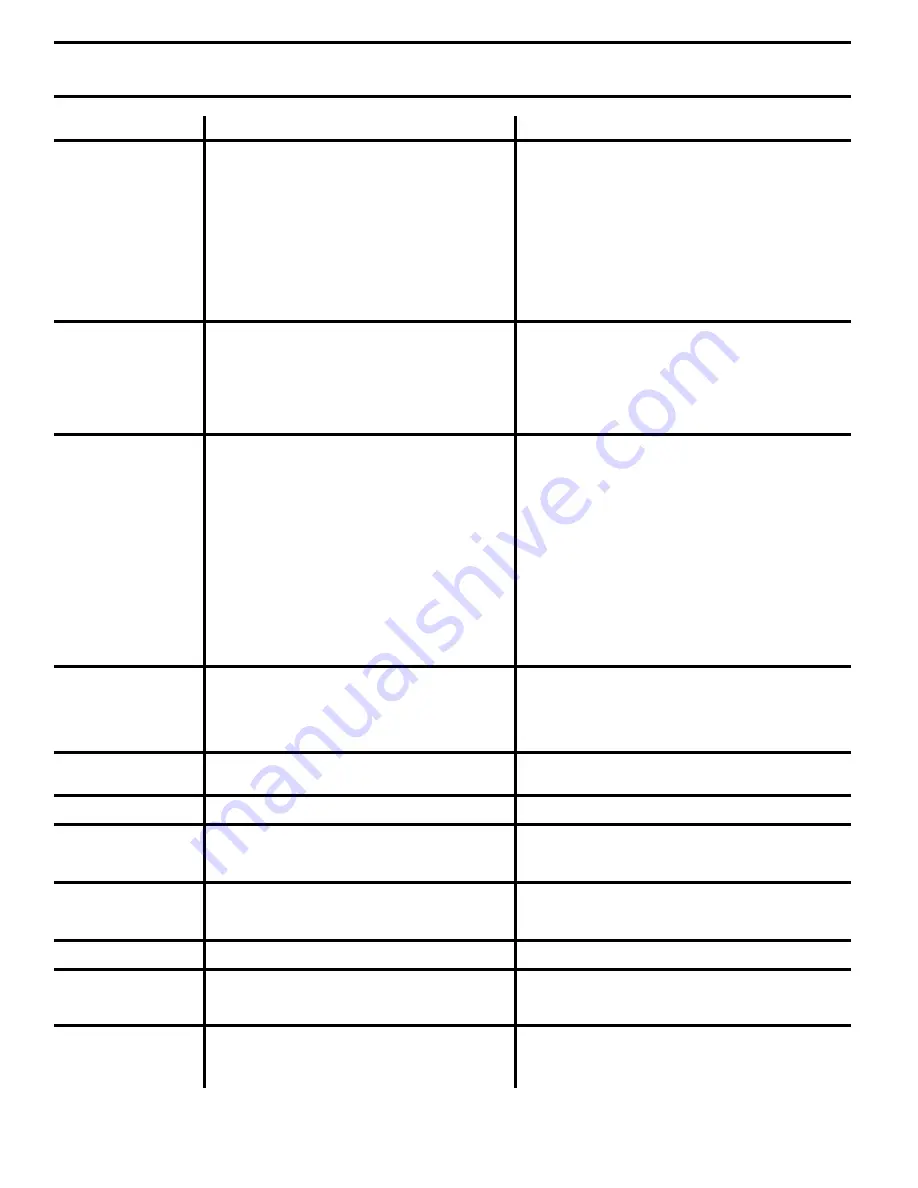

20

Will not start

1. Out of fuel. 1. Fill fuel tank.

2. Engine not “CHOKED” properly. 2. See “TO START ENGINE” in Operation section.

3. Engine fl ooded. 3. Wait several minutes before attempting to start.

4. Dirty air cleaner. 4. Clean or replace air cleaner cartridge.

5. Water in fuel. 5. Drain fuel tank and carburetor, and refi ll tank with

fresh gasoline.

6. Clogged fuel tank. 6. Remove fuel tank and clean.

7. Loose spark plug wire. 7. Make sure spark plug wire is seated properly on

plug.

8. Bad spark plug or improper gap. 8. Replace spark plug or adjust gap.

9. Carburetor out of adjustment. 9. Make necessary adjustments.

Hard to start

1. Throttle control not set properly. 1. Place throttle control in “FAST” position.

2. Dirty air cleaner. 2. Clean or replace air cleaner cartridge.

3. Bad spark plug or improper gap. 3. Replace spark plug or adjust gap.

4. Stale or dirty fuel. 4. Drain fuel tank and refi ll with fresh gasoline.

5. Loose spark plug wire. 5. Make sure spark plug wire is seated properly on

plug.

6. Carburetor out of adjustment. 6. Make necessary adjustments.

Loss of power

1. Engine is overloaded. 1. Set depth stake for shallower tilling.

2. Dirty air cleaner. 2. Clean or replace air cleaner cartridge.

3. Low oil level/dirty oil. 3. Check oil level/change oil.

4. Faulty spark plug. 4. Clean and regap or change spark plug.

5. Oil in fuel. 5. Drain and clean fuel tank and refi ll, and clean

carburetor.

6. Stale or dirty fuel. 6. Drain fuel tank and refi ll with fresh gasoline.

7. Water in fuel. 7. Drain fuel tank and carburetor, and refi ll tank with

fresh gasoline.

8. Clogged fuel tank. 8. Remove fuel tank and clean.

9. Spark plug wire loose. 9. Connect and tighten spark plug wire.

10. Dirty engine air screen. 10. Clean engine air screen.

11. Dirty/clogged muffl er. 11. Clean/replace muffl er.

12. Carburetor out of adjustment. 12. Make necessary adjustments.

13. Poor compression. 13. Contact an authorized service center/department.

Engine overheats

1. Low oil level/dirty oil. 1. Check oil level/change oil.

2. Dirty engine air screen. 2. Clean engine air screen.

3. Dirty engine. 3. Clean cylinder fi ns, air screen, and muffl er area.

4. Partially plugged muffl er. 4. Remove and clean muffl er.

5. Improper carburetor adjustment. 5. Adjust carburetor to richer position.

Excessive bounce/

1. Ground too dry and hard. 1. Moisten ground or wait for more favorable soil

diffi cult handling

conditions.

Soil balls up or clumps

1. Ground too wet. 1. Wait for more favorable soil conditions.

Engine runs but tiller

1. Drive control bar is not engaged. 1. Engage drive control.

won’t move

2. V-belt not correctly adjusted. 2. Inspect/adjust V-belt.

3. V-belt is off pulley(s). 3. Inspect V-belt.

Engine runs but labors

1. Tilling too deep. 1. Set depth stake for shallower tilling.

when tilling

2. Throttle control not properly adjusted. 2. Check throttle control setting.

3. Carburetor out of adjustment. 3. Make necessary adjustments.

Tines will not rotate

1. Shear pin(s) broken. 1. Replace shear pin(s).

Hard to shift into gear

1. Gears not timed. 1. Briefl y engage drive control bar and release or rock

tiller forward and backward until are able to shift

gears.

Tiller shuts off when

1. Shift lever set in between counter rotating till 1. Shift to either counter rotating till position or forward

drive control bar

position and forward rotating till position. rotating till position.

engaged

2. Tines jammed. 2. Clear tines.

PROBLEM

CAUSE

CORRECTION

TROUBLESHOOTING POINTS