7

ASSEMBLY

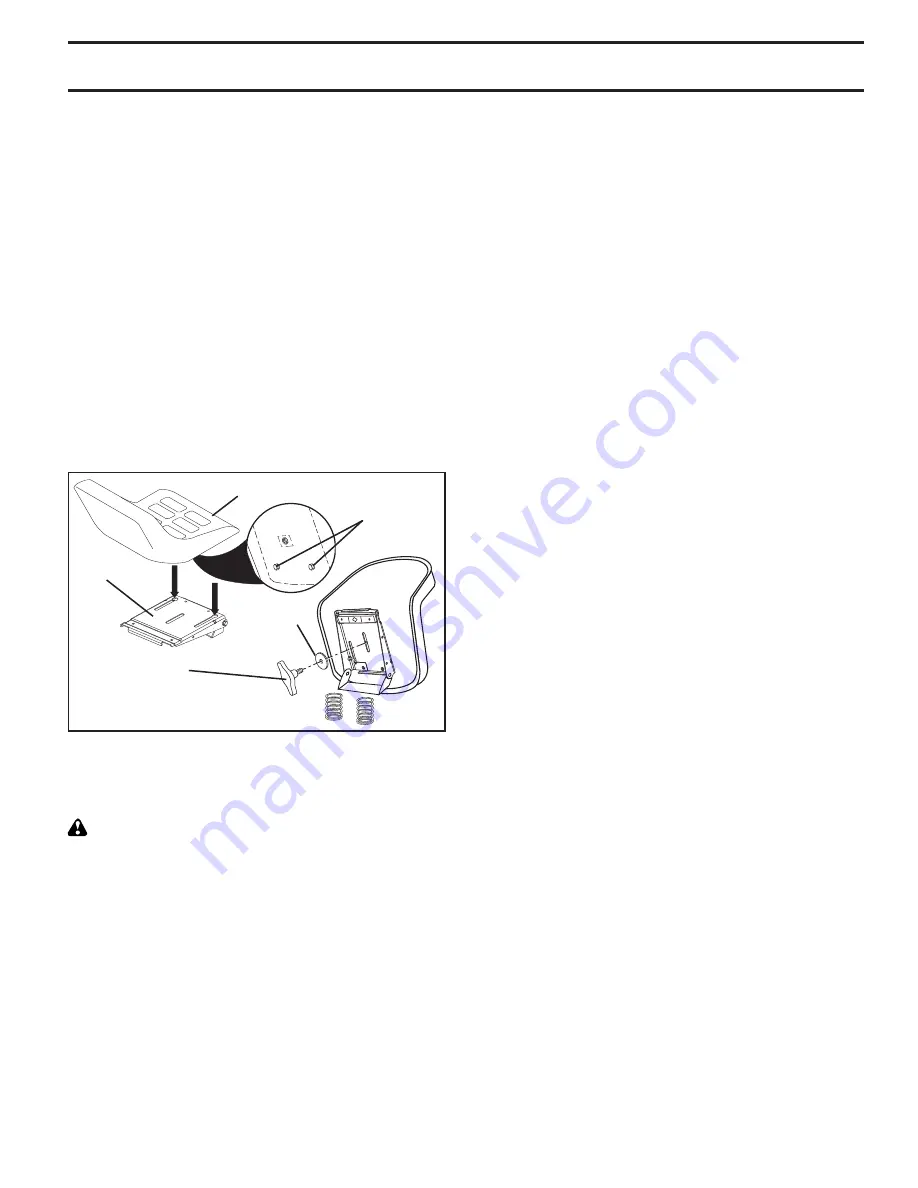

Fig. 3

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob.

• Remove adjustment knob and flat washer securing

seat to cardboard packing and set aside for assembly

of seat to tractor.

•

Pivot seat upward and remove from the cardboard pack-

ing. Remove the cardboard packing and discard.

• Place seat on seat pan so head of shoulder bolts are

positioned over the large slotted holes in pan.

• Push down on seat to engage shoulder bolts in slots

and pull seat towards rear of tractor.

• Pivot seat and pan forward and as sem ble adjustment

knob and flat washer loosely. Do not tighten.

• Lower seat into operating position and sit in seat.

•

Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

• Get off seat without moving its ad just ed position.

• Raise seat and tighten adjustment knob securely.

02615

ADJUSTMENT

KNOB

WASHER

02617

SEAT

PAN

SHOULDER

BOLTS

SEAT

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory

for shipping purposes. Correct tire pressure is important

for best cutting performance.

• Reduce tire pressure to PSI shown on tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

leveled. See “TO LEVEL MOWER” in the Service and

Adjustments section of this manual.

CHECK FOR POSITION OF ALL BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments sec-

tion of this manual. Verify that the belts are routed cor rect ly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see that

the brake is operating properly. See “TO CHECK BRAKE”

in the Service and Adjustments section of this manual.

NOTE:

You may now roll your tractor off the skid. Follow the

instructions below to remove the tractor from the skid.

WARNING:

Before start ing, read, un der stand and fol low

all in struc tions in the Op er a tion section of this man u al. Be

sure tractor is in a well-ventilated area. Be sure the area in

front of tractor is clear of other peo ple and objects.

TO ROLL TRACTOR OFF SKID (See Op er a tion

section for location and function of con trols)

• Raise attachment lift lever to its highest po si tion.

•

Release parking brake by depressing clutch/brake ped al.

• Place gearshift lever in neutral (N) po si tion.

• Roll tractor forward off skid.

•

Remove banding holding the deflector shield up against

tractor.

Continue with the instructions that follow.

✓

CHECKLIST

BEFORE YOU OPERATE YOUR NEW TRAC TOR, WE

WISH TO ASSURE THAT YOU RECEIVE THE BEST

PERFORMANCE AND SATISFACTION FROM THIS

QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

✓

All assembly instructions have been com plet ed.

✓

No remaining loose parts in carton.

✓

Battery is properly prepared and charged.

✓

Seat is adjusted comfortably and tightened securely.

✓

All tires are properly inflated. (For shipping purposes,

the tires were overinflated at the factory).

✓

Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

✓

Check mower and drive belts. Be sure they are routed

properly around pulleys and inside all belt keepers.

✓

Check wiring. See that all connections are still secure

and wires are properly clamped.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

✓

Engine oil is at proper level.

✓

Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

✓

Become familiar with all controls, their location and

function. Operate them before you start the engine.

✓

Be sure brake system is in safe operating condition.

✓

Be sure Operator Presence System and Reverse Op-

eration System (ROS) are working properly (See the

Operation and Maintenance sections in this manual).