7

Your new riding mower has been assembled at the factory with the exception of those

parts left unassembled for shipping purposes. To ensure safe and proper operation of your

riding mower all parts and hardware you assemble must be tightened securely. Use the

correct tools as necessary to insure proper tightness.

ASSEMBLY/PRE-OPERATION

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Stan dard wrench sizes you need

are listed below.

(1) 3/4" wrench

(1) 1/2" wrench

(1) Utility knife

(1) Tire pressure gauge

When right or left hand is mentioned in

this manual, it means when you are in the

operating position (seated behind the steer-

ing wheel).

TO REMOVE RIDING MOWER FROM

CARTON

UNPACK CARTON

1. Cut along dotted lines on all four panels

of carton. Remove carton and top frame

as one unit.

2. Remove packing materials from riding

mower.

NOTE:

Only cut carton with a short blade

utility knife, a long blade or saw can puncture

tires on unit.

HOW TO SET UP YOUR RIDING

MOWER

INSTALL STEERING COLUMN

1. Insert steering shaft into mount and se-

curely fasten with bolt, washer, and nut

provided.

2. Insert pin into hole in steering shaft.

3. Slide plastic cover over steering shaft

and into position.

4. Slide steering shaft protective foam cover

over shaft.

5. Position front wheels of the riding mower

so they are pointing straight forward.

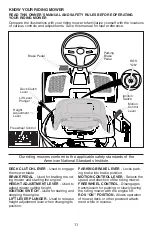

Plastic Cover

Steering

Shaft

Mount

Nut

Washer

Pin

Bolt

Steering Shaft

Foam Cover

Steering Wheel

Adapter

Insert

Washer

Nut

Steering Shaft

6. Remove steering wheel adapter from

steering wheel and slide adapter onto

steering shaft.

7. Press steering wheel into position on

shaft, install large washer, and tighten

nut securely.

8. Snap steering wheel insert into center of

steering wheel securely.

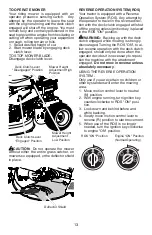

INSTALL SEAT

1. Pivot seat upward and remove from the

cardboard packing. Remove the card-

board packing and discard.

2. Place seat on seat pan so head of shoul-

der bolt is positioned over large slotted

hole in pan.

3. Push down on seat to engage shoulder

bolt in slot and pull seat towards rear of

riding mower.

024

66

Seat Pan

Shoulder

Bolt

Seat