10

OPERATION

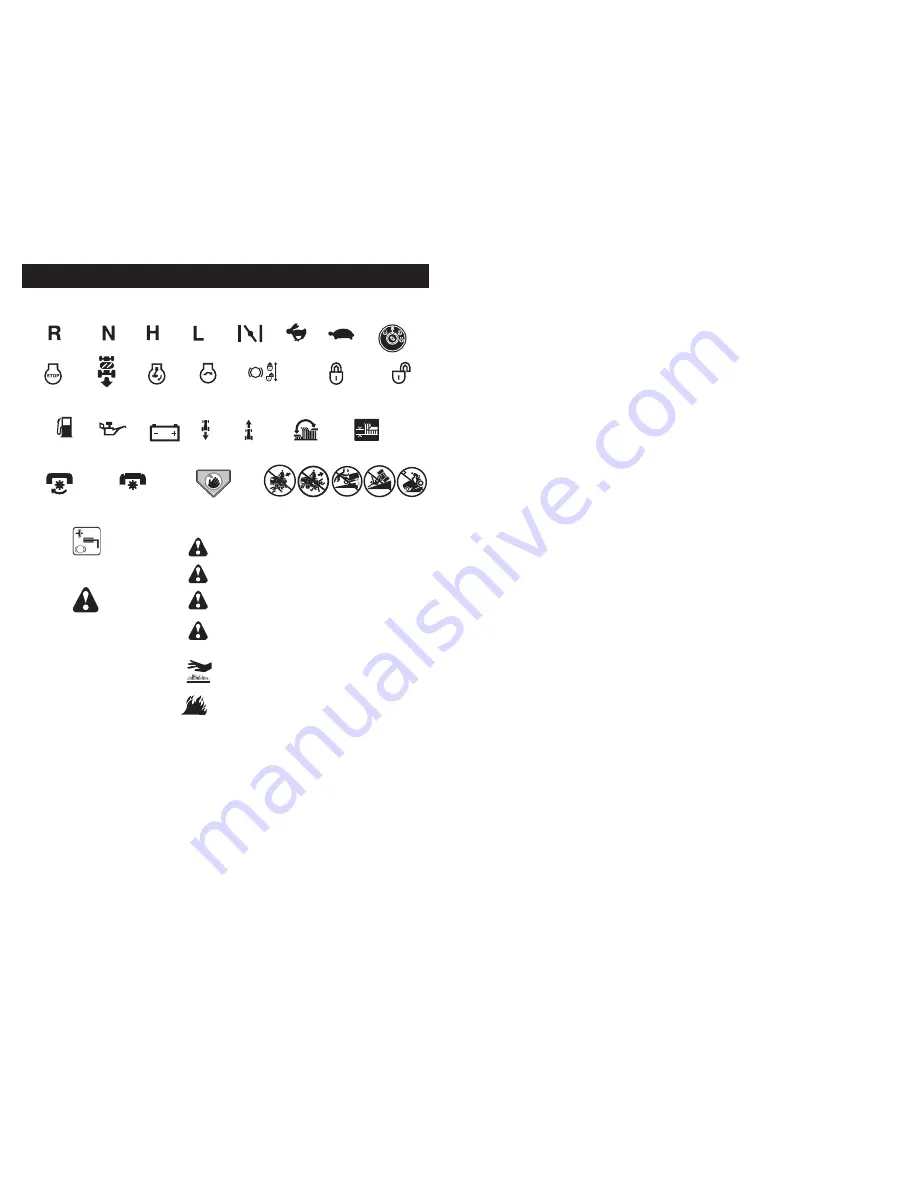

These symbols may appear on your riding mower or in literature supplied with the product.

Learn and understand their meaning.

DANGER, KEEP HANDS

AND FEET AWAY

KEEP AREA CLEAR

SLOPE HAZARDS

15

15

(SEE SAFETY RULES SECTION)

BATTERY

REVERSE

FORWARD

FAST

SLOW

ENGINE ON

ENGINE OFF

OIL PRESSURE

FUEL

CHOKE

MOWER HEIGHT

PARKING BRAKE

LOCKED

PARKING BRAKE

UNLOCKED

REVERSE

NEUTRAL

HIGH

LOW

ATTACHMENT

CLUTCH ENGAGED

PARKING BRAKE

ATTACHMENT

CLUTCH DISENGAGED

P

ENGINE START

MOWER LIFT

Failure to follow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury

and/or property damage.

DANGER

indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING

indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION

indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION

when used

without

the alert symbol,

indicates a situation that

could result in damage

to the tractor and/or engine.

FIRE

indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage.

HOT SURFACES

indicates a hazard which,

if not avoided,

could result in death, serious injury

and/or property damage.

BRAKE/CLUTCH

PEDAL

REVERSE

OPERATION

SYSTEM (ROS)

IGNITION SWITCH

35

KEY PART

NO. NO.

DESCRIPTION

KEY PART

NO. NO.

DESCRIPTION

NOTE:

All component dimensions given in U.S. inches

1 inch = 25.4 mm

1

532 44 21-38 WHEEL ASM (REAR)

2

532 12 17-48 WASHER, 16 GA.

3

812 00 00-01 E-CLIP

6

532 15 69-72 SPACER AXLE

7

874 78 04-28 HCS 1/4-20 X 1-3/4 GR 5 ZD

8

532 44 18-51 WELMENT SUPPORT AXLE RH

9

532 44 19-36 SUBASM FINAL DRIVE

10

817 00 05-12 SCREW 5/16 - 18 X 3/4

11

532 43 67-41 BRACKET.SUPPORT.RH

12

532 43 61-48 CASE CHAIN RH

13

532 43 72-80 BEARING BALL 6207-SRS

14

532 43 71-76 SPROCKET DRIVEN 37 TOOTH

15

532 44 25-51 TUBE INPUT HEX

16

532 43 61-53 CHAIN PRIMARY DRIVE

17

532 43 72-82 BEARING BALL 6204-3-2RS

18

532 43 61-49 CASE CHAIN LH

19

818 05 10-10 SCREW 10 - 24 X 5/8 PAN HEAD

TORX

20

532 12 49-31 WASHER THRUST .75 X 1.230

22

532 43 66-96 WELMENT SUPPORT AXLE LH

23

818 10 10-08 SCREW TORX #10 - 14 X 1/2

32

532 43 61-51 BLOCK TENSION CHAIN

33

532 43 61-50 SPRING ADJUSTER TENSION

34

877 10 10-40 PIN CLEVIS 5/16 X 2-1/2

36

532 43 57-22 SHAFT INPUT CLUTCH

37

532 43 61-52 SPROCKET SPLINED 14 TOOTH

39

532 43 04-70 BEARING BALL

40

532 43 69-39 ARM BRAKE

41

532 10 95-53 SWITCH INTLK CL MWR GRY

4 TERM

43

873 80 05-00 NUT LOCK HEX W/INSERT

5/16 - 18 UNC

44

532 43 66-52 COVER END HEX

45

532 43 61-54 SPRING DRIVE

47

532 43 69-49 BRACKET MOUNT CABLE LRV

B

48

817 54 10-16 SCREW.HEX.HEAD WASH.10-

24X1.00

51

532 43 67-39 BRACKET SUPPORT LH

53

873 90 06-00 LOCK NUT, FLANGED

54

532 43 57-26 BEARING BALL

55

532 43 77-77 COVER WHEEL CLUTCH

57

532 43 65-59 WHEEL FRICTION

59

532 44 10-97 PLATE.CLUTCH.DRIVE

60

532 43 77-87 PLATE PRESSURE DRIVE

62

532 43 77-86 PLATE CLUTCH BRAKE

63

532 43 77-85 PLATE PRESSURE BRAKE

65

532 43 57-23 PLATE PRESSURE MASTER

66

532 43 57-24 BEARING THRUST 20MM

67

532 43 57-25 PLATE THROWOUT

68

532 43 57-28 BEARING BALL LOOSE

69

532 43 57-27 COVER CLUTCH

70

532 41 15-55 GRIP LEVER

71

532 43 68-65 TUBE SHIFT LRV

72

872 11 04-06 BOLT CARR.

73

873 68 04-00 NUT CROWNLOCK 1/4 - 20 UNC

75

532 43 67-58 BRACKET MOUNT SHIFT

76

532 18 39-00 HUB SHIFT

78

532 42 90-55 SPACER NYLON .866 X 1.25 X

.250

79

874 78 04-12 BOLT.FIN.HEX.1/4-20 UNC X .75

80

810 04 04-00 WASHER LOCK HVY HLCL

SPRING

81

819 09 12-10 WASHER 9/32 X 3/4 X 10 GA.

84

819 11 16-10 WASHER 11/32 X 1.00 X 10 GA.

85

532 43 69-14 SPRING FRICTION PACK

86

532 43 73-04 BUSHING PACK FRICTION FD2

87

532 43 69-48 WASHER PLASTIC

88

532 43 67-01 STUD PACK FRICTION

89

532 43 72-99 SPACER PACK FRICTION FD2

90

819 11 14-16 WASHER.11/32 X 7/8 X 16 GA.

91

532 43 69-24 SUBASM.LINK.SHIFT

94

532 43 69-18 WELDMENT.SHIFT.FD2

95

532 43 68-66 PLATE.SHIFT

96

532 43 77-67 DRUM CLUTCH MULTI DISC

97

532 43 69-25 SUBASM LINK SHIFT PRIMARY

98

532 15 03-60 NUT LOCK CENTER 1/4 - 28

FNTHD

101 817 06 06-24 SCREW.3/8-16X1-1/2. SMGML.

TAP/R

102 532 08 67-77 THREAD.CUTTER

103 532 10 98-69 SWITCH.SEAT.

104 532 43 77-81 HUB CENTER

105 532 43 61-42 SPRING WAVE C125-H5

106 532 19 43-21 SPACER RETAINER

107 532 12 47-88 PIN COTTER

108 532 43 67-84 BUSHING.5/16IDX7/16ODX1/2

109 532 43 64-99 CAP.HUB.AXLE.1.50 X 1.00.

MS613

110 532 42 84-61 BRACKET SHIFTER FLEX

111 532

12

35-83 KEY.SQUARE.2.0 X .1845/.1865

112 818 10 10-12 SCREW TORX #10-14 X .750

113 873 90 05-00 NUT LOCK HEX FLANGE 5/16-

18

114 532 43 62-82 FLANGED BEARING

RIDING MOWER

MODEL NUMBER WELRVBA (96026000100)

DRIVE

PRODUCT NUMBER 960 26 00-01