26

PROBLEM

CAUSE

CORRECTION

Will not start

1

Out of fuel.

1

Fill fuel tank.

2

Bad spark plug.

2

Replace spark plug.

3

Dirty air filter.

3

Clean/replace air filter.

4

Water in fuel.

4

Empty fuel tank and carburetor, refill

tank with fresh gasoline and replace

fuel filter.

5

Loose or damaged wiring.

5

Check all wiring.

6

Engine valves out of adjustment.

6

Contact a qualified service center.

Hard to start

1

Dirty air filter.

1

Clean/replace air filter.

2

Bad spark plug.

2

Replace spark plug.

3

Weak or dead battery.

3

Recharge or replace battery.

4

Stale or dirty fuel.

4

Empty fuel tank and refill tank with

fresh, clean gasoline.

5

Loose or damaged wiring.

5

Check all wiring.

6

Engine valves out of adjustment.

6

Contact a qualified service center.

Engine will not

turn over

1

Clutch/brake pedal not depressed.

1

Depress clutch/brake pedal.

2

Deck clutch is engaged.

2

Disengage deck clutch.

3

Weak or dead battery.

3

Recharge or replace battery.

4

Blown fuse.

4

Replace fuse.

5

Corroded battery terminals.

5

Clean battery terminals.

6

Loose or damaged wiring.

6

Check all wiring.

7

Faulty ignition switch.

7

Check/replace ignition switch.

8

Faulty solenoid or starter.

8

Check/replace solenoid or starter.

9

Faulty operator presence switch(es).

9

Contact a qualified service center.

Engine clicks but will

not start

1

Weak or dead battery.

1

Recharge or replace battery.

2

Corroded battery terminals.

2

Clean battery terminals.

3

Loose or damaged wiring.

3

Check all wiring.

4

Faulty solenoid or starter.

4

Check/replace solenoid or starter.

Loss of power

1

Cutting too much grass/too fast.

1

Raise cutting height/reduce speed.

2

Build-up of grass, leaves and trash

under mower.

2

Clean underside of mower housing.

3

Dirty air filter.

3

Clean/replace air filter.

4

Low oil level/dirty oil.

4

Check oil level/change oil.

5

Faulty spark plug.

5

Clean & regap or change spark plug.

6

Stale or dirty fuel.

6

Empty fuel tank and refill tank with

fresh, clean gasoline.

7

Water in fuel.

7

Empty fuel tank and carburetor, refill

tank with fresh gasoline.

8

Spark plug wire loose.

8

Connect & tighten spark plug wire.

9

Dirty engine air screen/fins.

9

Clean engine air screen/fins.

10

Dirty/clogged muffler.

10

Clean/replace muffler.

11

Loose or damaged wiring.

11

Check all wiring.

12

Engine valves out of adjustment.

12

Contact a qualified service center.

Excessive vibration

1

Worn, bent or loose blade.

1

Replace blade. Tighten blade bolt.

2

Bent blade mandrel.

2

Contact a qualified service center.

3

Loose/damaged part(s).

3

Tighten loose part(s).

Replace damaged parts.

Engine continues to

run when operator

leaves seat with atta-

chment clutch engaged

1

Faulty operator-safety presence

control system.

1

Check wiring, switches and

connections. If not corrected,

Contact a qualified service center.

TROUBLESHOOTING CHART:

See ap pro pri ate section in manual un less di rect ed to service center.

19

BATTERY

Your riding mower has a battery charging

sys tem which is suf fi cient for normal use.

• Keep battery and connectors clean.

• Only recharge battery with charger

approved for a 12V 6 amp. hour battery.

• Charging with any other charger or an

automotive style charger can cause per-

manent damage to the battery.

• Charge battery for 24 hours for a full

charge.

NOTE:

The original equipment battery on

your riding mower is maintenance free. Do

not attempt to open or remove caps or cov-

ers. Adding or checking level of elec tro lyte

is not necessary.

WARNING:

Do not jump start battery.

Permanent damage to the battery or personal

injury may occur.

TRANSAXLE COOLING

Keep transaxle free from build-up of dirt and

chaff which can restrict cooling.

V-BELT

Check V-belt for deterioration and wear after

100 hours of operation and replace if neces-

sary. The belt is not ad just able. Re place belt

if it begins to slip from wear.

NOTE:

Al though multi-vis cos i ty oils (5W30,

10W30 etc.) im prove start ing in cold weather,

the oils will result in increased oil consumption

when used above 32°F. Check your engine

oil level more frequently to avoid possible

engine damage from running low on oil.

Change the oil after every 25 hours of

operation or at least once a year if the riding

mower is not used for 25 hours in one year.

Check the crankcase oil level before starting

the engine and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick

securely each time you check the oil level.

ENGINE

LUBRICATION

Only use high quality detergent oil rated with

API service classification SG-SL. Select the

oil’s SAE viscosity grade according to your

expected operating temperature.

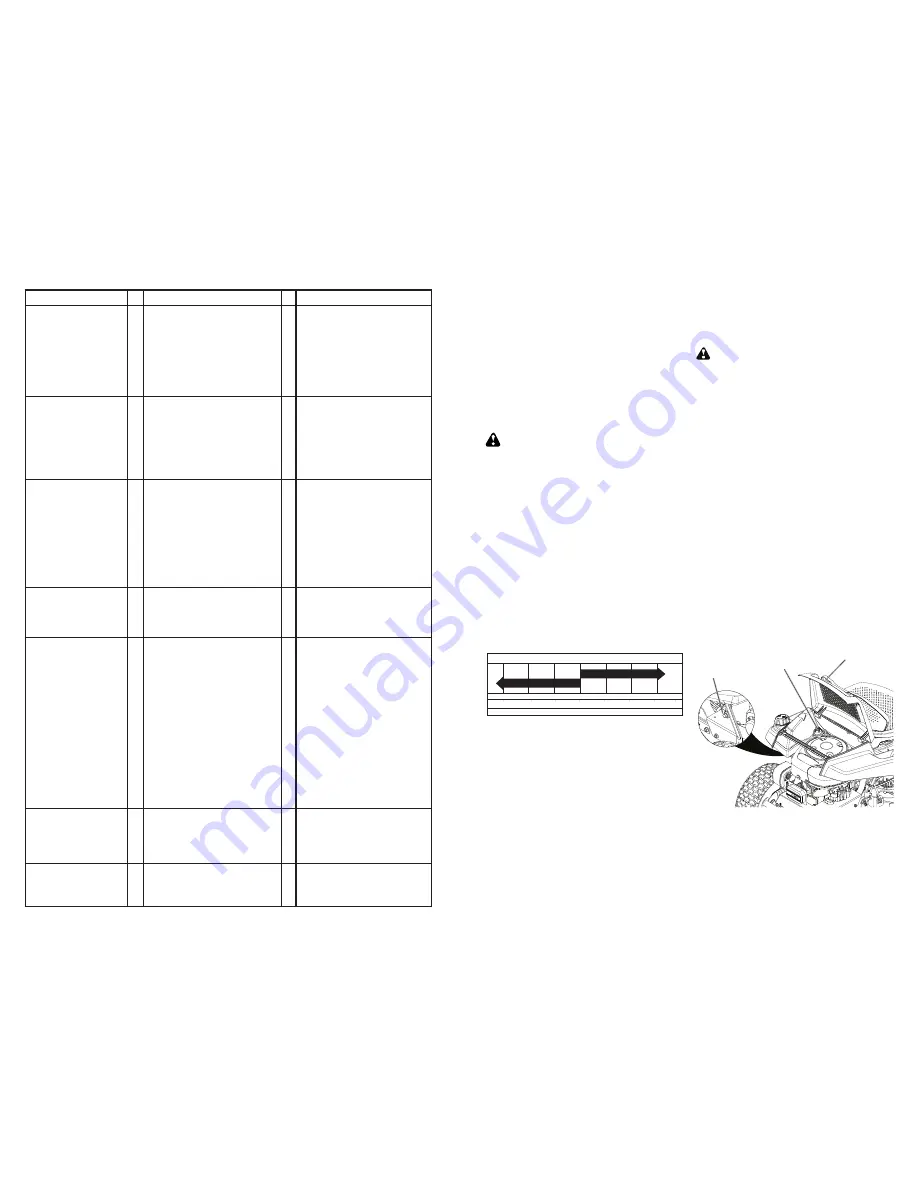

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

SAE VISCOSITY GRADES

-20 0 30 40

80

100

-30

-20 0 20 30

40

F

C

32

-10

10

60

5W-30

SAE 30

oil_visc_chart1_e

Engine Cover

Oil Fill Cap/Dipstick

Drain Plug

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

• Be sure riding mower is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

CAUTION:

If engine has been operated

for an extended period of time immediately

prior to draining oil, oil will be hot.

1. Lift engine cover.

2. Remove oil fill cap/dipstick. Be careful

not to allow dirt to enter the engine when

changing oil.

3. Position a container to catch oil.

4. Remove drain plug and drain oil into

container.

5. After oil has drained completely, replace

oil drain plug and tighten securely.

6. Refill engine with oil through oil fill dip-

stick tube. Pour slowly. Do not overfill.

For approximate capacity see “PROD-

UCT SPECIFICATIONS” section of this

manual.

7. Use gauge on oil fill cap/dipstick for

checking level. For accurate reading,

tighten dipstick cap securely onto the

tube before removing dipstick. Keep oil

at “FULL” line on dipstick. Tighten cap

onto the tube securely when finished.

8. Lower engine cover.