20

CLEAN AIR INTAKE/COOL ING AREAS

To ensure proper cooling, make sure the

grass screen, cooling fins, and other exter-

nal surfaces of the engine are kept clean

at all times.

Every 100 hours of operation (more often

under extremely dusty, dirty conditions),

remove the blower housing and other cooling

shrouds. Clean the cooling fins and external

surfaces as necessary. Ensure the cooling

shrouds are re in stalled.

NOTE:

Operating the engine with a blocked

grass screen, dirty or plugged cooling fins,

and/or cooling shrouds re moved will cause

engine damage due to overheating.

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff

to prevent engine dam age from overheating.

Clean with a wire brush or compressed air to

re move dirt and stub born dried gum fibers.

AIR FILTER

Your engine will not run properly using a

dirty air filter. Service air cleaner more often

under dusty conditions. See engine manual.

Engine Plate

Friction Disc

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could create

a fire hazard and/or dam age.

SPARK PLUG(S)

Replace spark plug(s) at the beginning of

each mowing season or after every 100

hours of operation, whichever occurs first.

Spark plug type and gap setting are shown

in “PROD UCT SPEC I FI CA TIONS” section

of this manual.

CLEANING

• Clean engine, battery, seat, finish, etc. of

all foreign matter.

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

• Protect painted surfaces with au to mo tive

type wax.

We do not recommend using a garden hose

or pressure washer to clean your riding

mower unless the engine and transmission

are covered to keep water out. Water in en-

gine or transmission will shorten the useful

life of your riding mower. Use compressed

air or a leaf blower to remove grass, leaves

and trash from riding mower and mower.

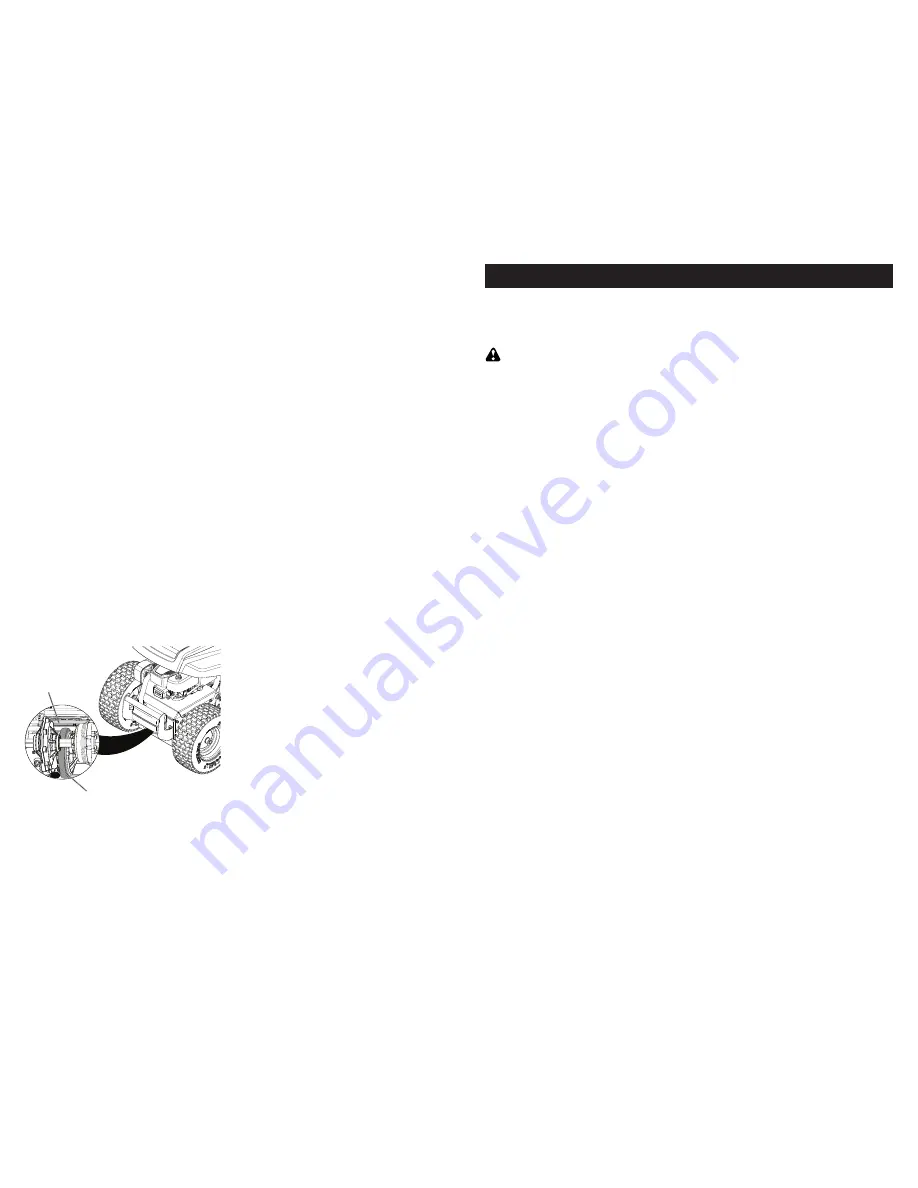

CLEANING FRICTION SURFACES

To ensure proper drive performance keep

the friction surfaces free from dirt, chaff and

excess rubber at all times.

Every 25 hours of operation, the friction

surfaces need to be rubbed clean with

isopropyl alcohol or other non-filming cleaner.

25

STORAGE

Immediately prepare your riding mower for

stor age at the end of the season or if the

riding mower will not be used for 30 days

or more.

WARNING:

Never store the riding mower

with gas o line in the tank inside a building

where fumes may reach an open flame or

spark. Allow the engine to cool before stor-

ing in any en clo sure.

MOWER

Remove deck from mower for winter storage.

When mower is to be stored for a period of

time, clean it thor oughly, remove all dirt,

grease, leaves, etc. Store in a clean, dry area.

1. Clean entire riding mower (See “CLEAN-

ING” in the Maintenance section of this

manual).

2. Inspect and replace belt, if nec es sary

(See belt re place ment in struc tions in the

Service and Ad just ments section of this

manual).

3. Lubricate as shown in the Main te nance

section of this man ual.

4. Be sure that all nuts, bolts and screws

are securely fastened. In spect moving

parts for damage, break age and wear.

Replace if nec es sary.

5. Touch up all rusted or chipped paint

surfaces; sand lightly before paint ing.

BATTERY

• Fully charge the battery for storage.

• If battery is removed from riding mower

for storage, do not store battery directly

on concrete or damp surfaces.

ENGINE

FUEL SYSTEM

IMPORTANT

: It is important to prevent

gum deposits from forming in essential fuel

system parts such as carburetor, fuel hose,

or tank during storage. Also, alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads

to separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage.

• Empty the fuel tank by starting the engine

and letting it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor clean er

products in the fuel tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE:

Fuel stabilizer is an acceptable al-

ternative in min i miz ing the formation of fuel

gum deposits during stor age. Add stabilizer

to gasoline in fuel tank or stor age container.

Always follow the mix ratio found on stabilizer

container. Run engine at least 10 minutes

after adding stabilizer to allow the sta bi liz er to

reach the carburetor. Do not empty the gas

tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace

with clean engine oil. (See “ENGINE” in the

Maintenance section of this man ual).

CYLINDER(S)

1. Remove spark plug(s).

2. Pour one ounce of oil through spark plug

hole(s) into cylinder(s).

3. Turn ignition key to “START” po si tion for

a few seconds to distribute oil.

4. Replace with new spark plug(s).

OTHER

• Do not store gasoline from one sea son to

another.

• Replace your gasoline can if your can starts

to rust. Rust and/or dirt in your gasoline

will cause problems.

• If possible, store your riding mower in doors

and cover it to give protection from dust

and dirt.

• Cover your riding mower with a suitable

protective cover that does not retain mois-

ture. Do not use plastic. Plas tic cannot

breathe which allows con den sa tion to form

and will cause your riding mower to rust.

IMPORTANT

: Never cover riding mower

while en gine and exhaust areas are still

warm.