33

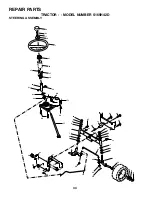

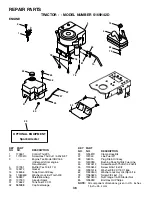

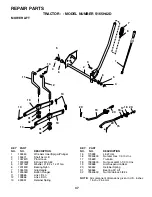

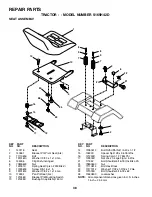

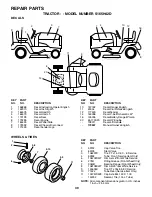

REPAIR PARTS

TRACTOR - - MODEL NUMBER S165H42D

DRIVE

KEY

PART

NO.

NO.

DESCRIPTION

KEY

PART

NO.

NO.

DESCRIPTION

1

- - - - - - -

Transaxle Peerless Model LTH2000

(Order parts from transaxle

manufacturer)

8

165619

Rod Shift Fender Adjust LT

10

76020416

Pin Cotter 1/8 x 1 CAD

14

10040400

Washer Lock Hvy Helical

16

73800500

Nut Lock Hex W/Ins 5/16-18 Unc P

19

73800600

Nut Lock Hex W/Wsh 3/8-16 Unc

21

106933X

Knob, Round 1/2-13

22

178141

Rod, Brake

24

73350600

Nut

25

106888X

Spring, Brake Rod

26

19131316

Washer

27

76020412

Pin Cotter 1/8 x 3/4 CAD.

28

175765

Rod, Parking Brake

29

71673

Cap, Parking Brake

30

174973

Bracket, Transaxle

32

74760512

Bolt Hex Hd 5/16-18 Unc x 3/4

34

175578

Shaft, Foot Pedal

35

120183X

Bearing, Nylon

36

19211616

Washer

37

1572H

Pin, Roll

38

165936

Pulley, Idler, Flat

39

74760648

Bolt

40

175461

Spacer, Split

41

175556

Keeper, Belt Idler

42

19131312

Washer 13/32 x 13/16 x 12 Gauge

47

127783

Pulley, Idler, V-Groove

48

154407

Bellcrank Clutch Grd Drv Stl

49

123205X

Retainer, Belt

50

74760624

Bolt

51

73680600

Nut Crownlock 3/8-16 UNC

52

73680500

Nut Crownlock 5/16-18 UNC

53

105710X

Link, Clutch

55

105709X

Spring, Return, Clutch

56

17060616

Screw 3/8-16 x 1

57

178138

V-Belt, Ground Drive

59

169691

Keeper, Center Span

61

17060612

Screw 3/8-16 x 3/4

62

8883R

Cover, Pedal

63

175410

Pulley, Engine

64

71170764

Bolt, Hex

65

10040700

Washer

66

154778

Keeper Belt Engine Hydro

69

142432

Screw

70

134683

Keeper Belt Engine

74

137057

Spacer, Axle

75

121749X

Washer 25/32 x 1-1/4 x 16 Gauge

76

12000001

E-Ring

77

123583X

Key, Square

78

121748X

Washer 25/32 x 1-5/8 x 16 Gauge

81

178140

Shaft Asm Cross

82

123782X

Spring Torsion T/A

83

19171216

Washer 17/32 x 3/4 x 16 Ga.

89

169373X428 Console, Hydro

90

142432

Screw Hex Wsh 1/4-20

95

178134

Rod Bypass

116

72140608

Bolt Rdhd Sq Neck 3/8-16 x 1.00

120

73900600

Nut Lock Flg. 3/8-16 Unc

145

74490540

Bolt Hex Flghd 5/16-18 x Gr. 5

150

175456

Spacer Retainer

151

19133210

Washer 13/32 x 2 x 10 Ga.

156

166002

Washer Srrted 5/16 ID x 1.125

158

165589

Bracket Shift Mount

159

165494

Hub Tapered Flange Shift LT

161

72140406

Bolt Rdhd Sqnk 1/4-20 x 3/4 Gr. 5

162

73680400

Nut Crownlock 1/4-20 Unc

163

74780416

Bolt Hex Fin 1/4-20 Unc x 1 Gr. 5

164

19091010

Washer 5/8 x .281 x 10 Ga.

165

165623

Bracket Pivot Lever

166

166880

Screw 5/16-18 x 5/8

168

165492

Bolt Shoulder 5/16-18 x .561

169

165581

Plate Fastening LT

171

17490608

Screw Thdrol 3/8-16 x 1/2 TY-TT

197

169613

Nyliner Snap-In 5/8” Id

198

169593

Washer Nyl 7/8 Id x .105

202

72110614

Bolt Carr Sh 3/8-16 x 1-3/4 Gr. 5

212

145212

Nut Hex Flange Lock

245

178122

Strap Torque LH

246

178121

Strap Torque RH

247

178127

Link, Transaxle

248

178847

Bolt Shoulder

249

1685H

Nut Lock 5/16-18 NC THD

250

17060612

Screw 3/8-16

251

17060516

Screw 5/16-18 x 1

252

19131616

Washer 13/32 x 1 x 16 Ga.

NOTE:

All component dimensions given in U.S. inches

1 inch = 25.4 mm

Summary of Contents for S165H42D

Page 44: ......