12638144 Installation, operation and maintenance manual – Synchronous Alternator – AG10 line - Horizontal l 17

3

RECEIPT, STORAGE AND HANDLING

3.1

RECEIPT

All supplied alternators are tested and are in proper

operating condition. The machined surfaces are protected

against corrosion. The packaging must be checked

immediately upon receipt to verify that it has not suffered

damage during transport.

ATTENTION

Any damage must be photographed,

documented and reported immediately to the

carrier, the insurer and to WEG. The lack of

notice will void the warranty.

ATTENTION

Additional parts supplied in packages should

be checked on receipt.

When lifting the package, the correct locations for

lifting, the weight stated in the documentation and / or

on the nameplate must be observed, as well as the

capacity and operation of lifting devices;

Alternators packed in crates should always be raised by

their own eyebolts or by appropriate forklift, but should

never be raised by their crates;

The package can never be overturned. Place on the

ground carefully (without causing impacts) to avoid

damage to the bearings;

Do not remove the grease for corrosion protection of

the end of the shaft, flange and coupling discs nor the

plugs closing holes of the terminal boxes;

These protections should remain in place until the final

assembly. After unpacking, you should make a

complete visual inspection of the alternator;

The shaft locking system should be removed just before

the installation and stored in a safe place to be used in

any future transportation of the alternator.

3.2

HANDLING

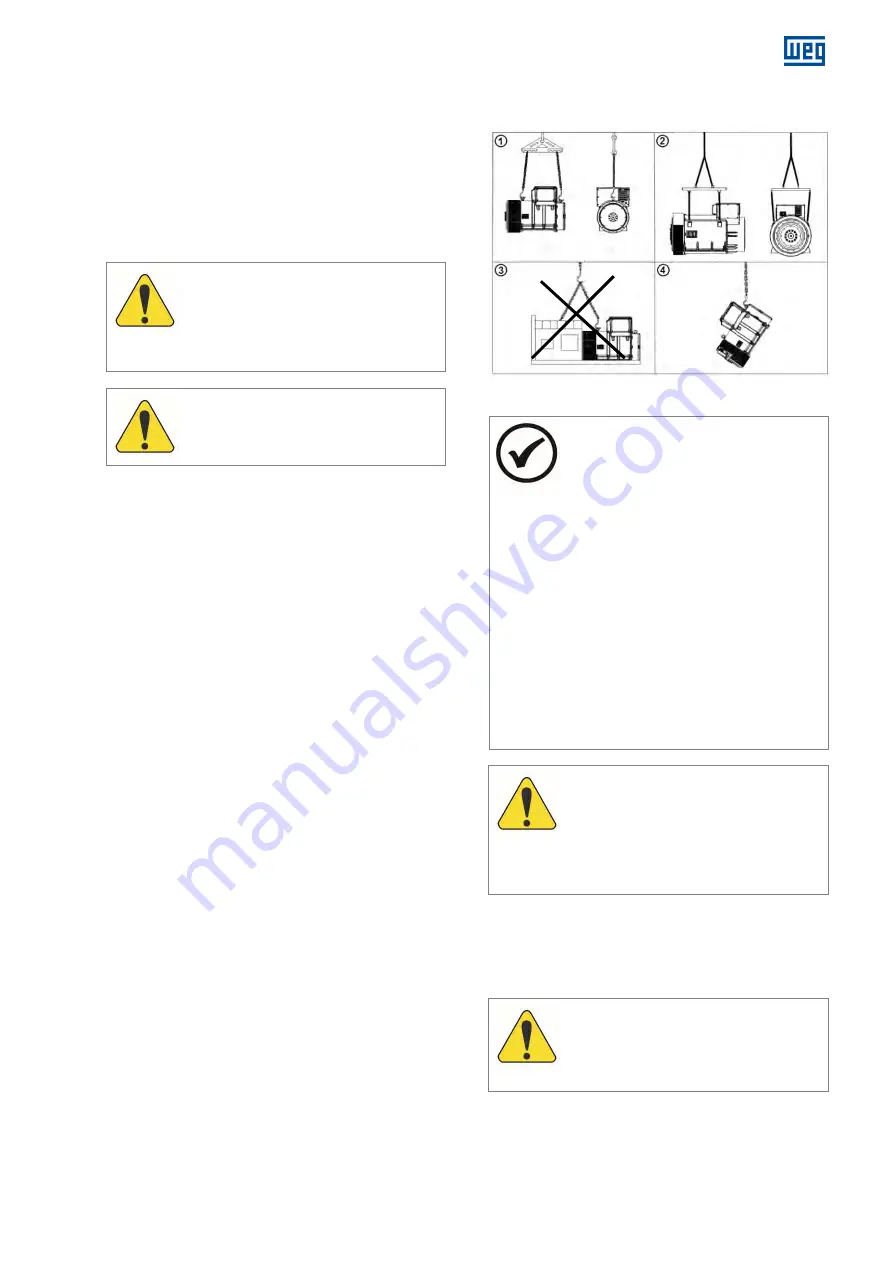

The position 1 of Figure 3.1, represents the correct way

of handling the alternators AG10 250, 280, 315 and

355;

The position 2 of Figure 3.1, represents the correct way

of handling the alternator AG10 400;

The positions 3 and 4 of Figure 3.1 represents the

incorrect ways of handling the alternators.

The alternator was designed with eyebolts for its lifting.

These eyebolts are designed to lift only the alternator,

additional loads are not permitted;

Cables and lifting devices must be appropriate.

Figure 3.1: Handling of alternator

NOTES

Observe weight indicated.

Do not lift and do not put the alternator on

the ground suddenly thus avoiding damage

to the bearings.

To lift the alternator, use only the existing

eyebolts. If necessary, use a crossbeam to

protect parts of the alternator.

The eyebolts on the covers, bearings,

terminal box, etc., only serve to handle

these components.

Never use the shaft to lift the alternator.

To move the alternator, it must be with the

shaft locked with the locking device

supplied with the alternator.

After removal of the locking device from the

front side, while lifting the alternator it

should not be inclined with the front

downwards at risk of falling of the rotor.

ATTENTION

Steel cables, clevises and lifting equipment

must be appropriate and be capable of

supporting the weight of the alternator, to

avoid accidents, damage to the alternator or

personal injury.

3.3

STORAGE

Any damage to paint or rust protections of machined parts

to be retouched.

ATTENTION

During storage, the heating elements (if any)

must remain connected to prevent water

condensation inside the alternator.