English

TROUBLESHOOTING AND MAINTENANCE

6.6 PREVENTIVE MAINTENANCE

!

DANGER!

Always turn off the mains power supply before touching any electrical component associated to the

inverter.

High voltage may still be present even after disconnecting the power supply. Therefore, wait at least

10 minutes for the complete discharge of the power capacitors.

Always connect the equipment frame to the protection earth (PE) at the suitable connection point.

!

WARNING!

The electronic boards have electrostatic discharge sensitive components.

Do not touch the

components or connectors directly. If needed, first touch the grounded mettalic frame or wear a

ground strap.

Do not perform any withstand voltage test: if needed, consult WEG.

The inverters require low maintenance when properly installed and operated.

presents main procedures

and time intervals for preventive maintenance.

provides recommended periodic inspections to be

performed every 6 months after inverter start-up.

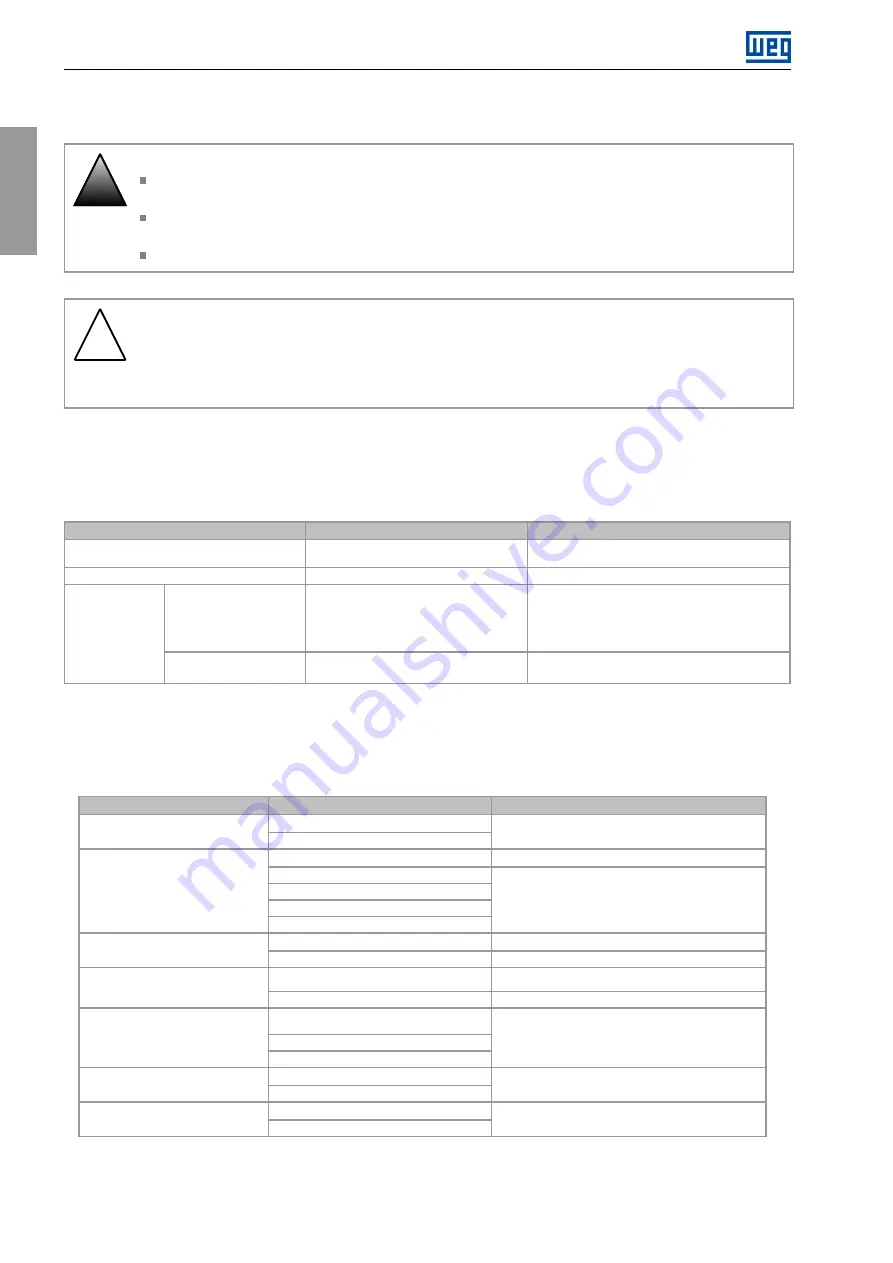

Table 6.3:

Preventive maintenance

Maintenance

Interval

Instructions

Fan replacement

After 50.000 operating hours

(1)

Replacement procedure according to

Figure 6.1

and

Replacement of the AUI board battery

Every 10 years

Refer to

Electrolytic

Capacitors

If the inverter is stored

(not in use):: “reforming”

Every

year,

counted

from

the

manufacturing date stated on the inverter

identification label.

Power inverter with single-phase or three-phase

voltage between 208 and 240 Vac, 50 or 60 Hz,

for at least 1 hour. Then, de-energize and wait at

least 24 hours before using the inverter (energize

again)

Inverter is being used:

Every 10 years

Contact WEG technical support

replace

(1)

The inverters are programmed at the factory for automatic control of the fans ( C1.5.1 = 3), so they only start when the temperature of the

heatsink increases. Therefore, the number of operating hours of the fans will depend on the operating conditions (motor current, output

frequency, temperature of the cooling air etc.). The inverter records in parameter D3.3 the number of hours that the fan remained ON. When

the fan reaches 50,000 hours of operation, the HMI will display alarm A177.

Table 6.4:

Recommended periodic inspections - every 6 months

Component

Problem

Corrective Action

Terminals, connectors

Loose screws

Tighten

Loose connectors

Fans/cooling system

Dirty fans

Cleaning

Abnormal noise

Replace fan. Refer to

and

Blocked fan

Proceed in reverse order to assemble a new fan

Abnormal vibration

Check the fan connection

Dust in the cabinet air filter

Printed circuit boards

Accumulation of dust, oil, humidity, etc

Cleaning

Odor

Replacement

Power

module/power

connections

Accumulation of dust, oil, humidity, etc

Cleaning

Loose connection screws

Tighten

DC Link capacitors (Intermediate

Circuit)

Discoloration/ odor / electrolyte leakage

Replacement

Expanded or broken safety valve

Frame expansion

Power resistors

Discoloration

Replacement

Odor

Heatsink

Dust accumulation

Cleaning

Dirty

90 | CFW900

Summary of Contents for CFW900

Page 2: ......