11371757 Installation, operation and maintenance manual – Squirrel cage motor – M line – Vertical

l 41

7.9.1.6

Procedure for changing the grease

In order to replace the POLYREX EM103 grease by one

of the alternative greases, the bearings must be opened to

remove the old grease and then filled with the new grease.

If it is not possible to open the bearings, the old grease

must be purged by applying new grease until it begins to

appear in the exit drawer with the motor running.

In order to replace the STABURAGS N12MF grease by

one of the alternative greases, you must first open the

bearings, completely remove the old grease, and then fill it

with new grease.

ATTENTION

Since there is no grease compatible with

STABURAGS N12MF, other grease must

not be injected in the attempt to purge it. This

procedure will not expel completely the old

grease and they will mix, which may cause

damage to the bearings.

ATTENTION

When the bearing is opened, inject the new

grease through the grease nipple to expel

the old grease found in the grease inlet

tube, and apply the new grease in the

rolling bearing, to the inner and outer

bearing caps, filling 3/4 of the empty

spaces. In case of double bearings (ball

b roller bearing), also fill 3/4 of the

empty spaces between the intermediate

rings.

Never clean the rolling bearing with cotton-

based cloths, because they may release

some lint, working as solid particles.

NOTE

WEG is not liable for the grease change or for

any damages arising from this change.

7.9.1.7

Low temperature greases

Table 7.4: Grease for application at low temperatures

Manufacturer

Grease

Constant

operating

temperature

(°C)

Application

Exxon Mobil

MOBILITH SHC

100

(Lithium Soap and

Synthetic Oil)

(-50 to +150)

Low

temperature

7.9.1.8

Grease compatibility

You can say that greases are compatible when the

properties of the mixture are within the property ranges of

the greases individually.

In general, greases with the same type of soap are

compatible; however, depending on the proportion of the

mixture, there might be incompatibility. Therefore, it is not

recommended to mix different types of grease without

consulting the grease supplier or WEG.

Some thickeners and basic oils cannot be mixed, because

they do not form a homogeneous mixture. In this case,

one cannot rule the possibility of hardening or softening of

the grease, or reduction of the dropping point of the

resulting mixture.

ATTENTION

Greases with different types of base must

never be mixed.

For example: Lithium-based greases must

never be mixed with sodium or calcium-

based greases.

7.9.1.9

Disassembly – vertical bearings

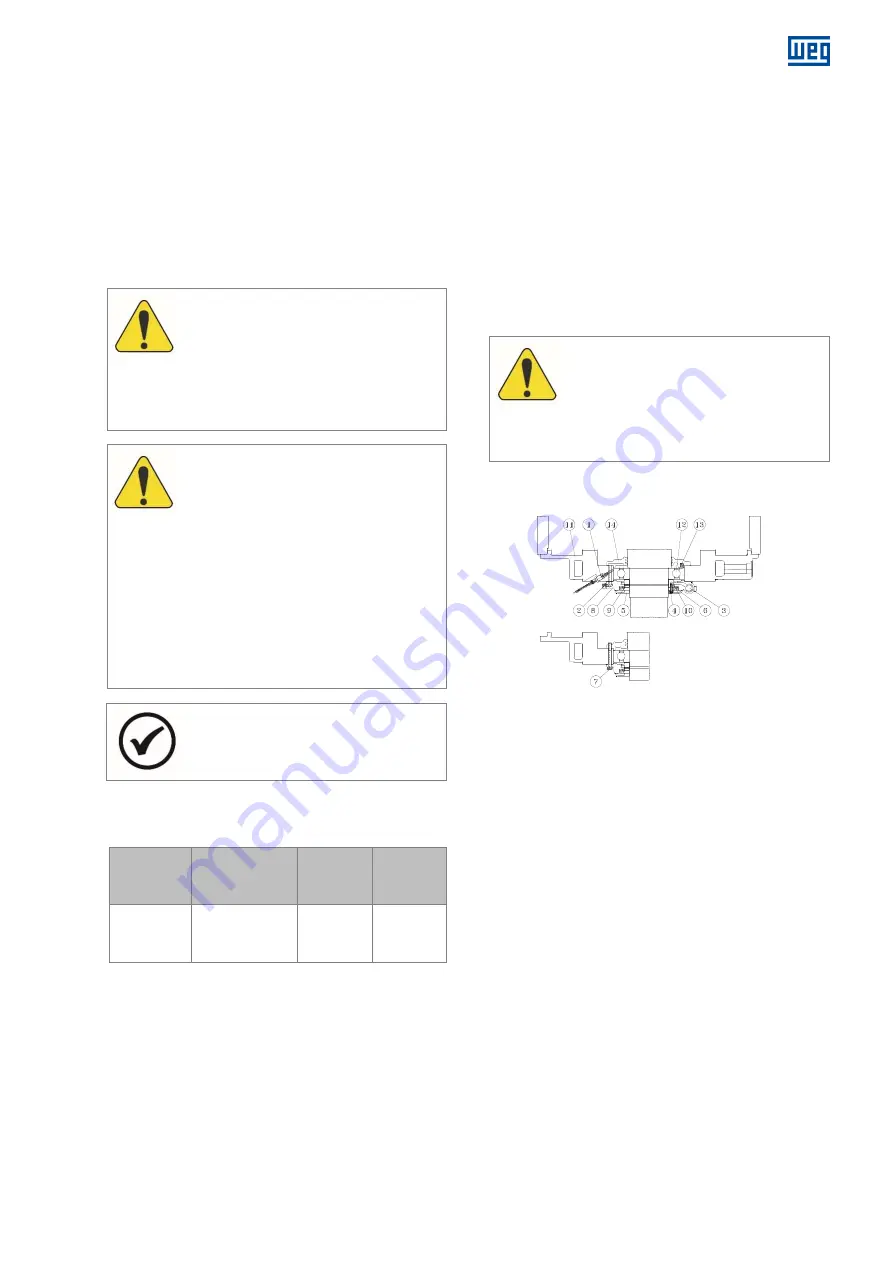

Figure 7.2: Lower bearing

Figure 7.2 legend:

1.

Temperature sensor

2.

Grease nipple

3.

Grease collecting drawer

4.

Screw

5.

Protection disc

6.

Labyrinth taconite seal

7.

Screw

8.

Outer bearing cap

9.

Screw

10.

Grease flinger

11.

Lower end shield

12.

Rolling bearing

13.

Spring

14.

Inner bearing cap

7.9.1.9.1

Before disassembling

Remove the extension tubes from the grease inlet and

outlet;

Thoroughly clean the external part of the bearing;

Remove the grounding brush (if any);

Remove the temperature sensors.