11371757 Installation, operation and maintenance manual – Squirrel cage motor – M line – Vertical

l 43

7.9.2.1

Lubrication instructions

Oil drainage: When it is necessary to change the bearing

oil, remove the oil outlet plug (3) and drain the oil

completely.

To fill the bearing with oil:

Close the oil outlet with the plug (3);

Remove the plug from the oil inlet or from the filter (1);

Fill it with the specified oil up to the level indicated in the

oil sight glass.

NOTES

1.

All threaded holes that are not used

must be closed with plugs and no fitting

may present leaks;

2.

The oil level is reached when the

lubricant can be seen approximately in

the middle of the sight glass;

3.

The use of a larger amount of oil will not

damage the bearing; but it can cause

leaks through the shaft seals;

4.

Never use hydraulic oil or mix it with the

bearing lubricant oil.

7.9.2.2

Oil type

The type and quantity of lubricant oil to be used are

specified on the nameplate affixed to the motor.

7.9.2.3

Oil change

The bearing oil change must be done according to the

intervals, which depend on the bearing operating

temperature, shown in Table 7.5:

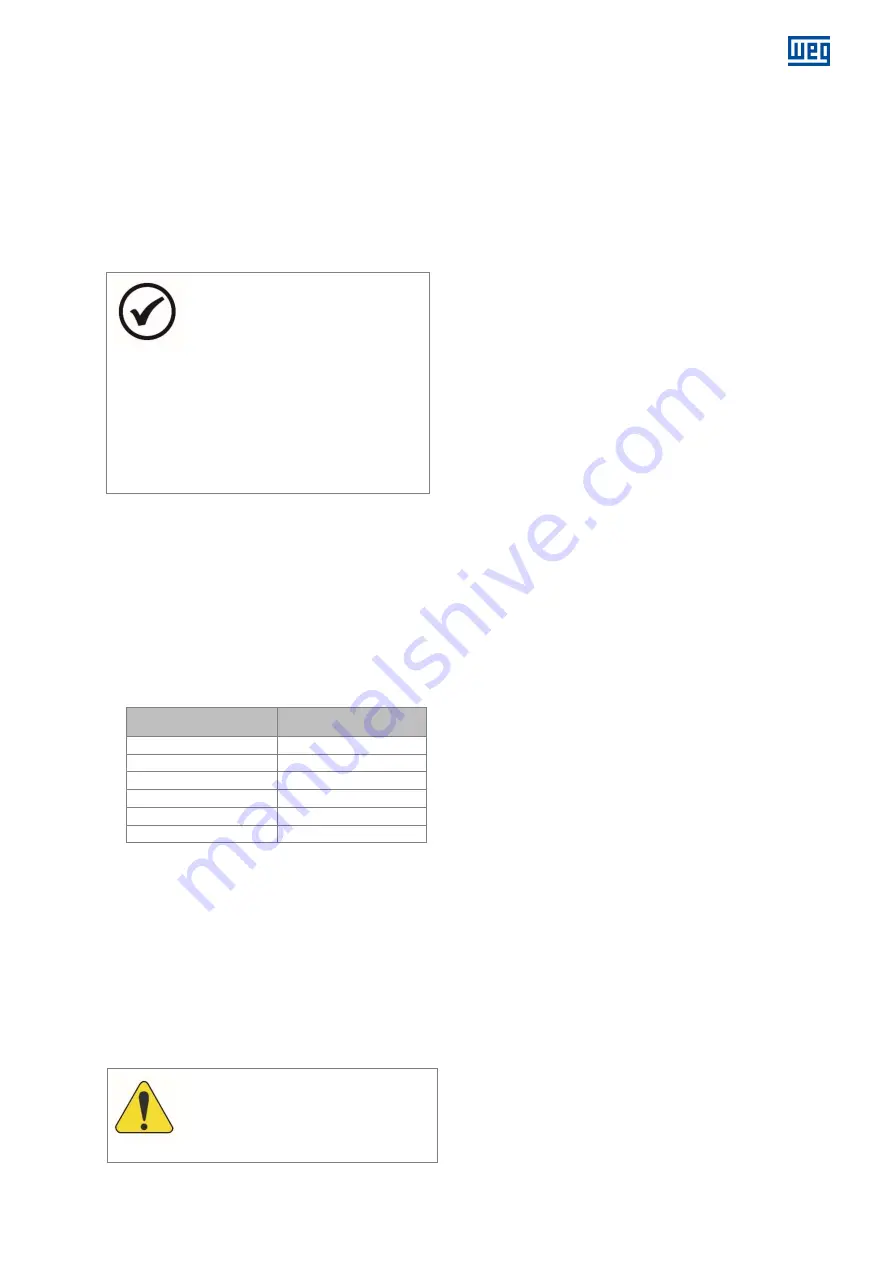

Table 7.5: Oil change intervals

Bearing operating

temperature

Bearing oil change

intervals

Below 75 ºC

20,000 hours

Between 75 and 80 ºC

16,000 hours

Between 80 and 85 ºC

12,000 hours

Between 85 and 90 ºC

8,000 hours

Between 90 and 95 ºC

6,000 hours

Between 95 and 100 ºC

4,000 hours

The lifespan of the bearings depends on their operating

conditions, on the motor operating conditions and on the

maintenance procedures.

Proceed according to the following directions:

The oil selected for the application must have the

proper viscosity for the bearing operating temperature.

The type of oil recommended by WEG already

considers these criteria;

Insufficient quantity of oil may damage the bearing;

The minimum recommended oil level is reached when

the lubricant can be seen in the lower part of the oil

sight glass with the motor stopped.

ATTENTION

The oil level must be inspected daily and

must remain in the middle of the oil sight

glass.

7.9.2.4

Bearing operation

The system start, as well as the first hours of

operation, must be monitored carefully.

Before starting, check:

If the used oil complies with the specification on the

nameplate;

The lubricant characteristics;

The oil level;

The alarm and trip temperatures set for the bearing.

During the first start, it is necessary to stay alert for

unusual vibrations or noises. If the bearing does not

operate in a silent and smooth way, the motor must be

shut down immediately.

The motor must operate for some hours until the bearing

temperatures stabilize. In case of overheating of the

bearings, the motor must be shut down for inspection of

the bearings and temperature sensors.

Check if there is no oil leak through the plugs, gaskets or

shaft end.