11371757 Installation, operation and maintenance manual – Squirrel cage motor – M line – Vertical

l 15

3.2.1

Motor positioning

Vertical motors are supplied with lifting lugs at the drive

end DE and non-drive end NDE.

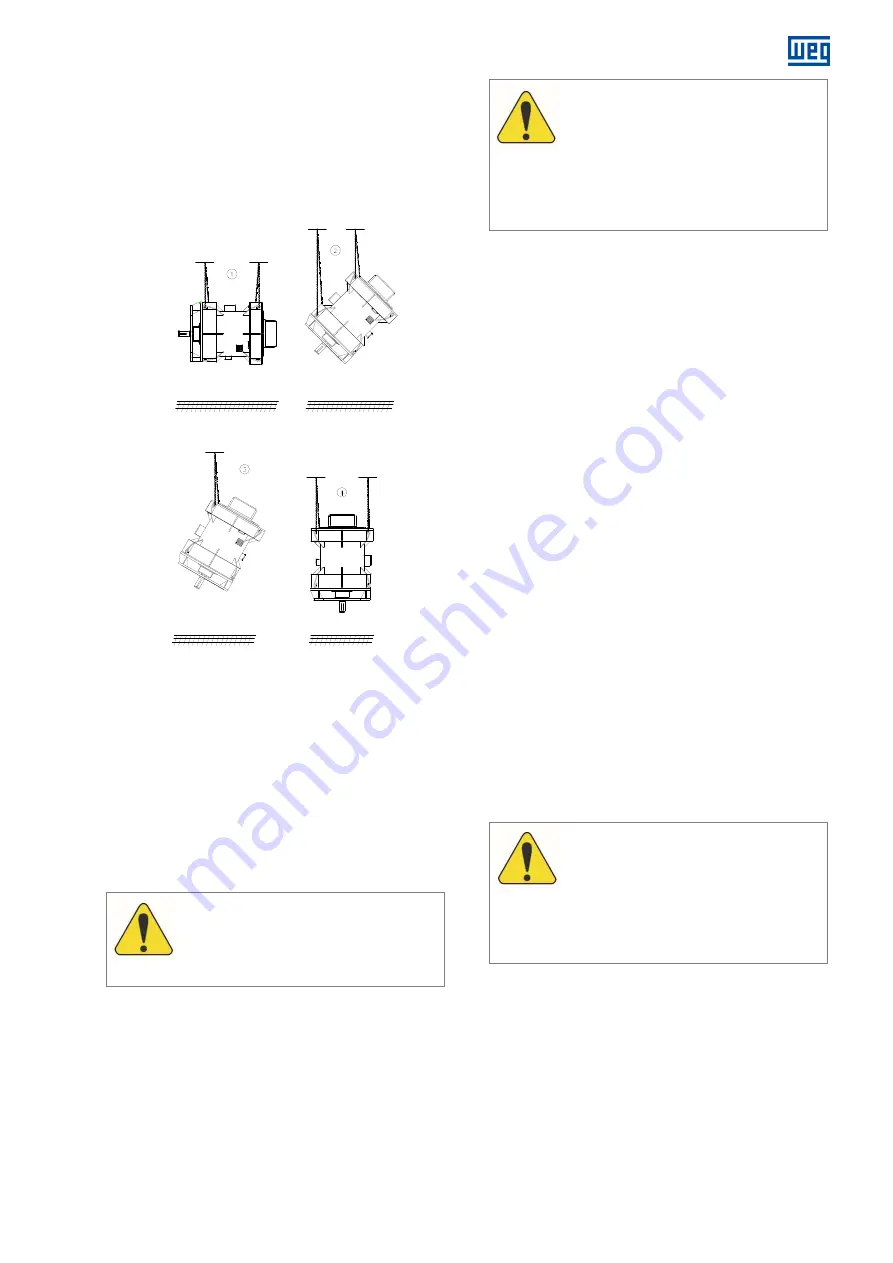

Some motors are transported in the horizontal position

and need to be moved to the original position. Figure 3.2

shows how to move motors from the horizontal position to

the vertical position and vice versa.

Figure 3.2: Motor positioning

In order to position vertical motors, proceed according to

the following recommendations:

1.

Lift the motor using the side lifting lugs and two

hoists;

2.

Lower the motor drive end (DE) and lift the non-drive

end (NDE) at the same time until balance is reached;

3.

Loosen the DE cables and turn the motor 180º in

order to enable the connection of these cables to the

other lifting lugs of the NDE;

4.

Connect the loose cables to the NDE lifting lugs and

lift them until the motor reaches the vertical position.

ATTENTION

Failure to comply with these

recommendations may cause damage to the

equipment, personal injuries or both.

3.3

STORAGE

If the Motor is not installed immediately after reception, it

must remain inside the package and stored in a location

protected against moisture, vapors, sudden changes in

temperature, rodents and insects.

The motor must be stored in vibration-free locations in

order to avoid bearing damage.

ATTENTION

Space heaters must remain powered during

storage in order to avoid moisture

condensation inside the motor.

Any damage to the paint or corrosion

protection of the machined parts must be

repaired.

3.3.1

Outdoor storage

The motor must be stored in a dry location, free of

flooding and vibrations.

Repair any damages on the package before storing the

motor, which is needed to ensure proper storage

conditions.

Place the motor on platforms or foundations that ensure

protection against humidity from the ground and prevent it

from sinking into the soil. Free air circulation underneath

the motor must be assured.

The cover used to protect the motor against the bad

weather must not be in contact with its surfaces. In order

to ensure free air circulation between the motor and such

covers, place wooden blocks as spacers.

3.3.2

Extended storage

When the motor is stored for a long period of time (two

months or more) before start-up, it is exposed to

external agents, such as temperature variations,

moisture, aggressive agents, etc.

The empty spaces inside the motor – such as rolling

bearings, terminal boxes, and windings – are exposed to

humidity, which can cause condensation, and,

depending on the degree of air contamination,

aggressive substances may also penetrate these empty

spaces.

Consequently, after long periods of storage, the winding

insulation resistance may drop below the acceptable

values, internal components, such as rolling bearings,

may oxidize, and the lubricant power of the lubricant

agent in the bearings may be adversely affected.

All of these influences increase the risk of damages

before starting the motor.

ATTENTION

To assure that the motor warranty be valid, it

is necessary to make sure that all preventive

measures described in this manual, such as

constructive aspects, maintenance,

packaging, storage, and periodical

inspections, are followed and recorded.

The extended storage instructions are valid for motors

that remain stored for long periods (two months or more)

before start-up or motors already installed that are in a

prolonged stoppage, considering the same period.

3.3.2.1

Storage location

In order to ensure the best storage conditions for the

motor during long periods, the chosen location must

strictly meet the criteria described in sections 1.1.1.1.1

and 3.3.2.1.2.