www.weg.net

WECM / Emerald eZA Manual | 19

DANGER!

g

The LED in OFF condition doesn`t mean that there is no power supply to the drive;

g

Make sure that the input power supply is disconnected before do any maintenance in the product.

If the Fire Mode function is active, the failures will be detected, but ignored by WECM / Emerald eZA, i.e., will not

block the IGBTs. If the motor was spinning, will continue spinning. For more information see item 6.5

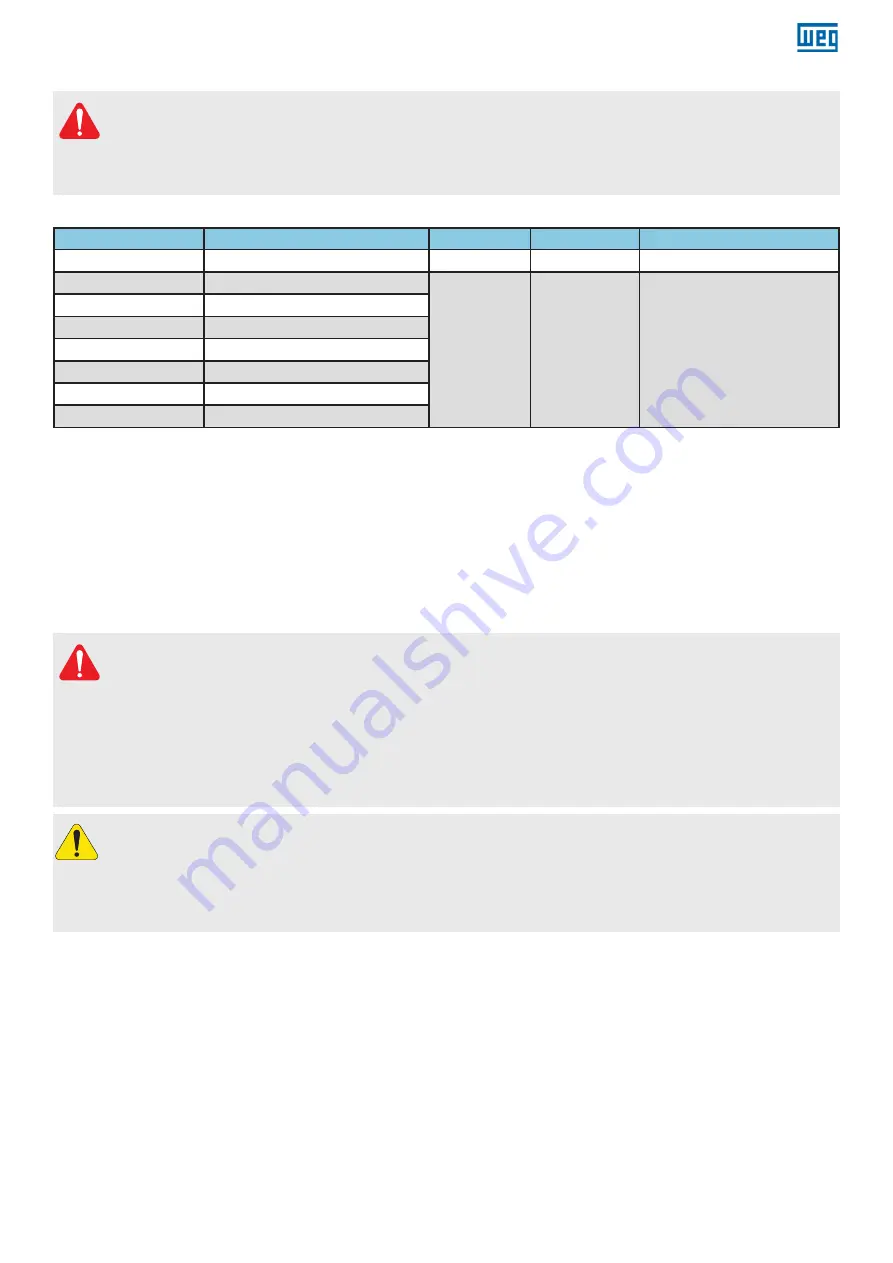

The LED #1 will blink in case of any fault. Table 10 indicates the blinking behavior according the fault type:

Table 10 -

Blinking periods

Fault

ON time (s)

Off time (s)

Wait / interval time (off) (s)

2

Under voltage

0,1

0,1

-

3

Over current (shor-circuit)

0,25

0,25

2

6

Over voltage

7

Over load

8

Over speed

9

Communication timeout

10

Over Temperature

11

Locked rotor

The blinking behavior according to fault type

Communication timeout fault: failure in the drive to motor communication;

Watchdog timeout fault: failure in the drive processor / software.

7.1. INFORMATION FOR CONTACTING TECHNICAL SUPPORT

For technical support and servicing, it is important to have the following information in hands:

Motor model, Batch number, and manufacturing date available in the motor nameplate (refer to item 4).

Installed software version available in the drive label (refer to item 4).

8. MAINTENANCE

DANGER!

g

Before any service is performed, ensure that motor is it at standstill, disconnected from the power supply and

protected against accidental energization. Even when the motor is stopped, dangerous voltages may be present

in space heater terminals;

For motors with permanent magnet rotor (WECM and Emerald eZA), the motor assembly and disassembly require

the use of proper devices due to the attracting or repelling forces that occur between metallic parts. This work must only

be performed by a WEG Authorized service center specifically trained for such an operation. People with pacemakers

cannot handle these motors. The permanent magnets can also cause disturbances or damages to other electric

equipment and components during maintenance.

ATTENTION!

g

Motor disassembly during the warranty period must be performed by a WEG authorized service center only;

g

Regularly inspect the operation of the motor, according to its application, and ensure a free air flow. Inspect

the seals, the fastening bolts, the bearings, the vibration and noise levels, the drain operation, etc. The lubrication interval

is specified on the motor nameplate.