Installation and Operating Manual

Page

32

Printed: 02/2015

6.2. Connection of steam heater

Ensure proper drainage of condensate. To ensure proper control for partial load operation,

each steam battery must be equipped with a separate condensate drain.

6.3. Connection of refrigerant line

Observe the instructions in section 6.1.

Prior to connection, the exchanger and lines must be tested for leakage (to determine whether

the shielding gas is still pressurised).

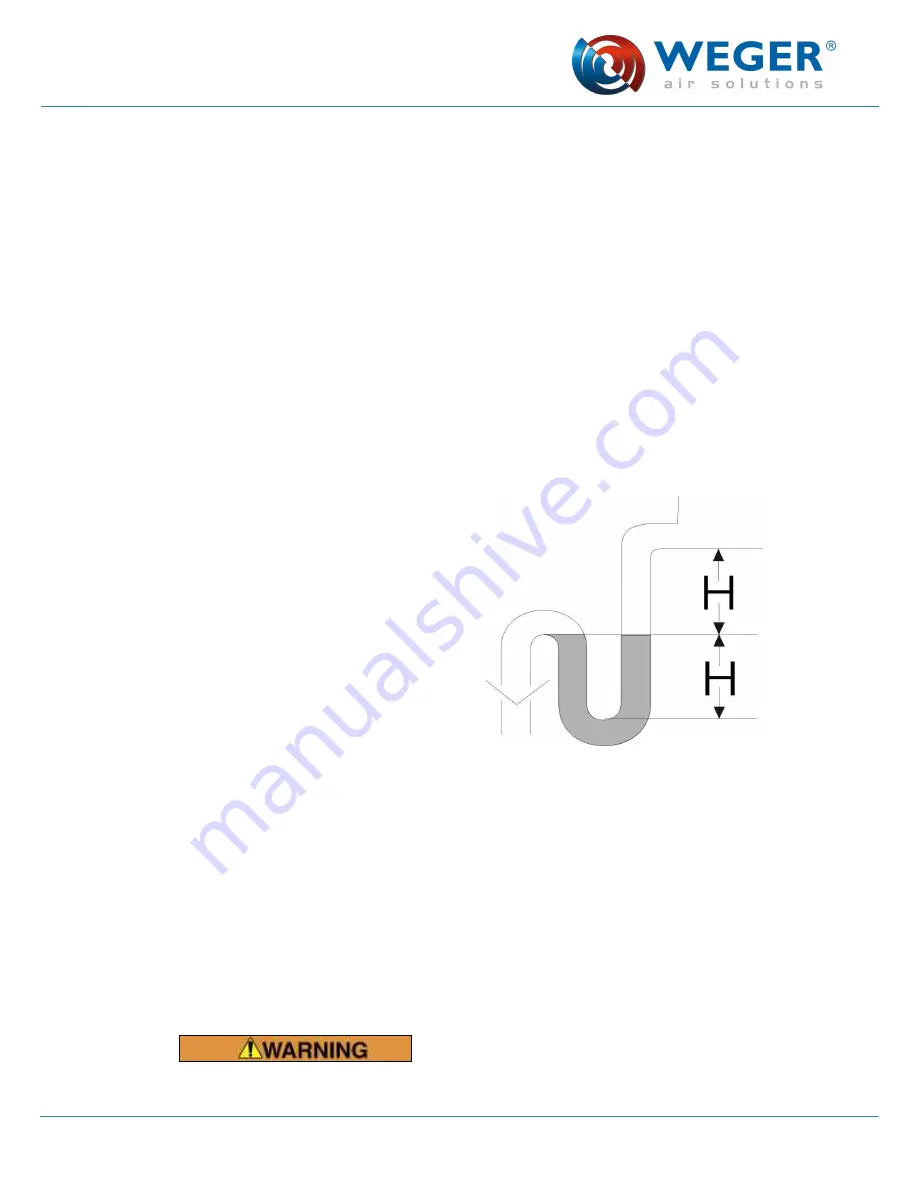

6.4. Condensate drain

Install a siphon at each drain adapter. The effective head in mm must correspond to the

maximum static internal pressure of the unit (hydrostatic head) + 15 mm.

Example:

Total effective pressure = 1196 Pa (see data

sheet)

Dynamic effective pressure = 2 x 83 Pa (see

data sheet)

Total effective pressure - dynamic effective

pressure = Pstat = 1030 Pa

1 mm hydrostatic head = 9.81 Pa

H = 1030 / 9.81 + 15 mm

= 120 mm

The connecting line for condensate must have a diameter of minimum 40 mm and be

equipped with a siphon with backflow protection. It must feature an exposed outlet to the

waste water system but must not be directly connected to it. Outlets at different pressure

levels must be equipped with separate siphons.

6.5. Air duct connections

The air duct connections to the unit must be free of stress and air-tight. To prevent

propagation of structural vibration, we recommend installing elastic connecting adapters or

insulating connecting frames that are mounted without stress between the unit and the duct.

Risk of injury from electric shock! Install all necessary earthing conductors/potential

equalization equipment.

Summary of Contents for DIWER EVO DP80 Series

Page 2: ......

Page 39: ...Installation and Operating Manual Page 37 Printed 02 2015...

Page 62: ...Installation and Operating Manual Page 60 Printed 02 2015 Notes...

Page 63: ...Installation and Operating Manual Page 61 Printed 02 2015 Notes...

Page 64: ...Installation and Operating Manual Page 62 Printed 02 2015 Notes...