8�2

Connection

Î

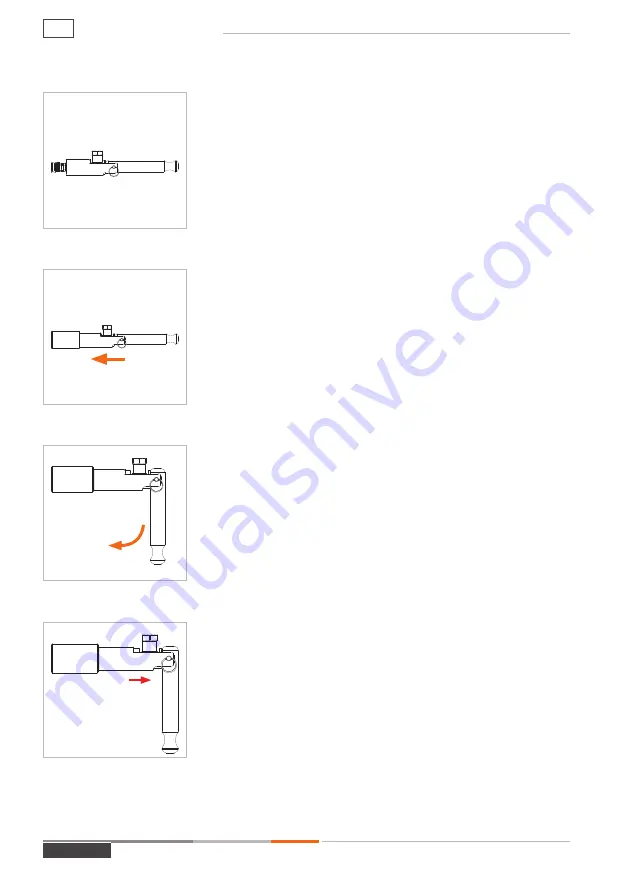

Move the clamping lever (Pos. 2) to the straight starting

position (

Figure 2

).

Î

Grip the connector by its base unit (Pos. 1) and plug it up

to the stop straight into the test piece (

Figure 3

). Doing

so will prevent any damage to the front seal caused by

any sharp edges on the test piece and ensure a correct

connection.

Attention:

Insert the connector carefully and not with force

into the test piece.

Î

Actuate the clamping lever (Pos. 2) by 90° downwards

(

Figure 4

). The connector tightens itself to the test piece

and creates a pressure-tight connection.

Attention:

Make sure that the clamping jaws on the test

piece grip correctly, that the connector is seated properly

(it must not wobble) and that the pressure-tight connec-

tion has been made. Only then is the connector connected

correctly. Otherwise the connector may spring out of place

and medium may escape.

Î

Pull lightly on the connector (red arrow

Figure 5

) in the

direction opposite that of the connection to make sure

that the connector is firmly in place.

- The connector is now connected pressure-tight to the test

piece.

Î

To start the testing procedure, apply pressure to media

inlet ‘B1’.

Figure 2

Figure 3

Figure 4

Figure 5

pull backwards

MD-10015-L51-R1.1.0-03

Page 18

Operating instructions

AE