11

. TRO

UBLE

SH

O

O

TING

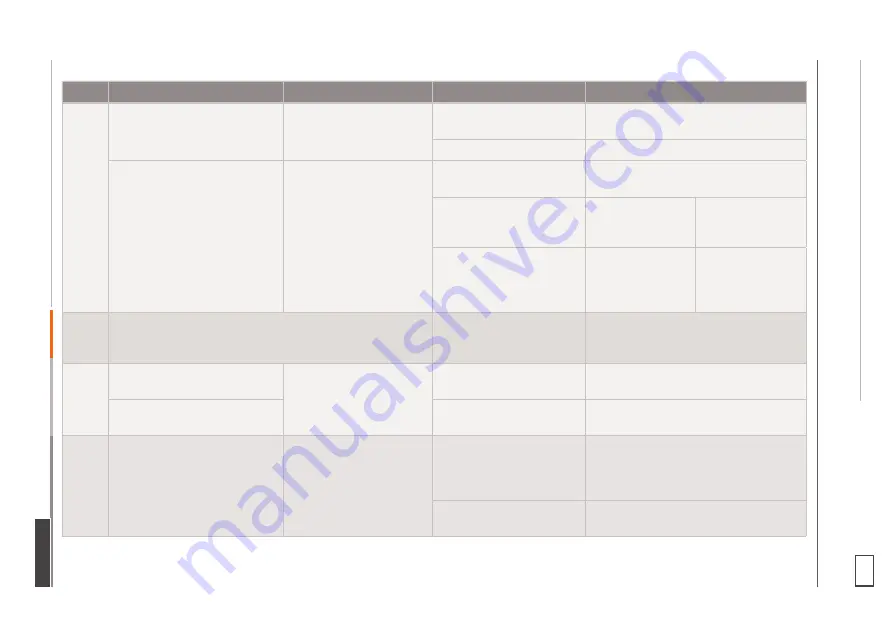

No�

Fault

Can be recognized by

Possible cause

Remedial measures

1

Gas leak during testing,

decreasing with increasing

pressure

Sounds of escaping gas

Incorrect connection

Stop the testing operation,

reconnect the connector

Inlet too rigid

Fit a flexible hose, for example

Gas leakage when pressure

increases

Sounds of escaping gas

Incorrect connection

Stop the testing operation,

reconnect the connector

Faulty front seal

Stop the testing

operation

Replace the front

seal, see

Chapter 9.4.1

Test piece damaged

Decide whether

to interrupt or

continue the

filling operation

Replace

test piece

2

The clamping lever is either seriously damaged or broken

Excessive mechanical

stress due to inappropri-

ate handling

Return the connector to WEH

for maintenance

3

Leakage on connector

Sounds of escaping gas

Defective

sealing components

Send the connector to WEH

for maintenance.

Fittings are leaky

Leakage in media inlet

Tighten up fittings, see

Chapter 7. Installation

4

Segments of the clamping

jaws do not separate widely

enough

Connector is seated too

loosely, it sits unsteadily

in the test piece

Wear

First check the test piece. If this is

defective, replace the test piece. If it is

in good condition, send the

connector to WEH for maintenance

Connector is not

correctly connected

Repeat the connecting procedure

MD-10015-L51-R1.1.0-03

Page 31

Oper

ating instructions

AE