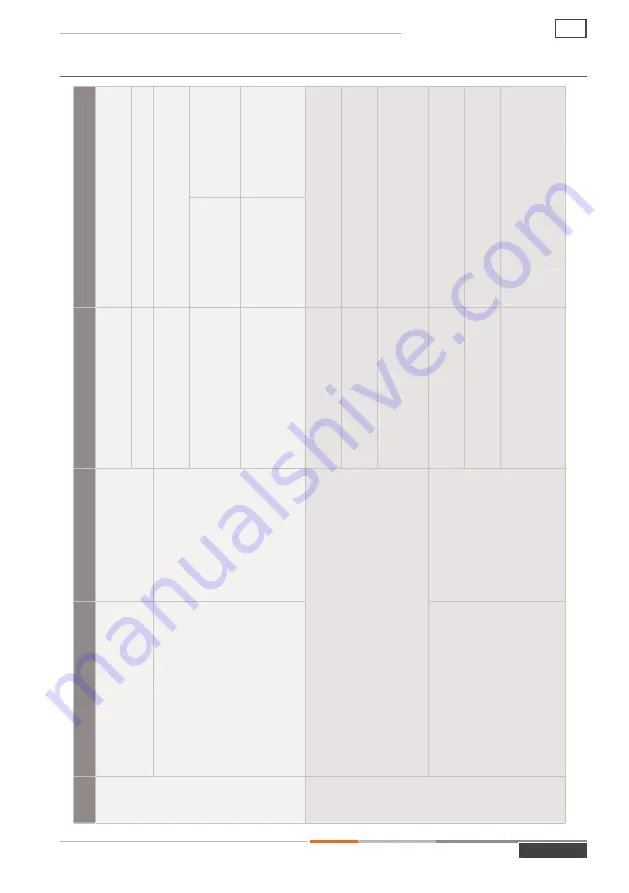

11. TROUBLESHOOTING

No

�

Fault

Can be r

ecogniz

ed b

y

Possible cause

Remedial measur

es

1

Gas leak during filling oper

ation, decr

easing with

incr

easing pr

essur

e

Sounds of

escaping gas

Incorr

ect

connection

St

op the filling oper

ation,

reconnect the connect

or

Inlet t

oo rigid

fit a flexible hose, for example

Gas leak when pr

essur

e

incr

eases

Sounds of escaping gas

Incorr

ect

connection

St

op the testing oper

ation,

reconnect the connect

or

Faulty fr

ont seal

St

op the testing

oper

ation

Replace the

fr

ont seal,

see

Damaged cylinder v

alv

e

Decide whether to interrupt the filling oper

ation

or t

o continue it

Replace cylinder valv

e

2

Saf

ety peg does not emer

ge fr

om the connect

or

when the pr

essur

e builds up

Saf

ety peg bent

End the filling oper

ation, send the

connect

or t

o WEH for maintenance

The filling pr

essur

e has

not y

et r

eached 15 bar

The filling pr

essur

e must equal 15–

20 bar for the saf

ety peg t

o emer

ge

Insufficient lubrication

Contaminated saf

ety peg

Replace the connect

or befor

e next

filling

oper

ation,

se

nd

the

connect

or t

o

WEH for maintenance

The saf

ety peg does not

retr

act

The actuation le

ver

cannot be opened

The system is not

depr

essuriz

ed enough

Check if cylinder v

alv

e is closed

Continue t

o depr

essuriz

e

Saf

ety peg becomes

jammed due t

o dr

y-running

Send the connect

or t

o WEH for

maintenance

Saf

ety peg becomes

jammed due t

o damage

Pr

ess the saf

ety peg int

o the

connect

or b

y hand or car

efully using

a t

ool. Send the connect

or t

o WEH for

maintenance

MD-10017-L51-R2.1.0-03

Page 29

Operating instructions

AE

Summary of Contents for TW54

Page 2: ......