4

9.

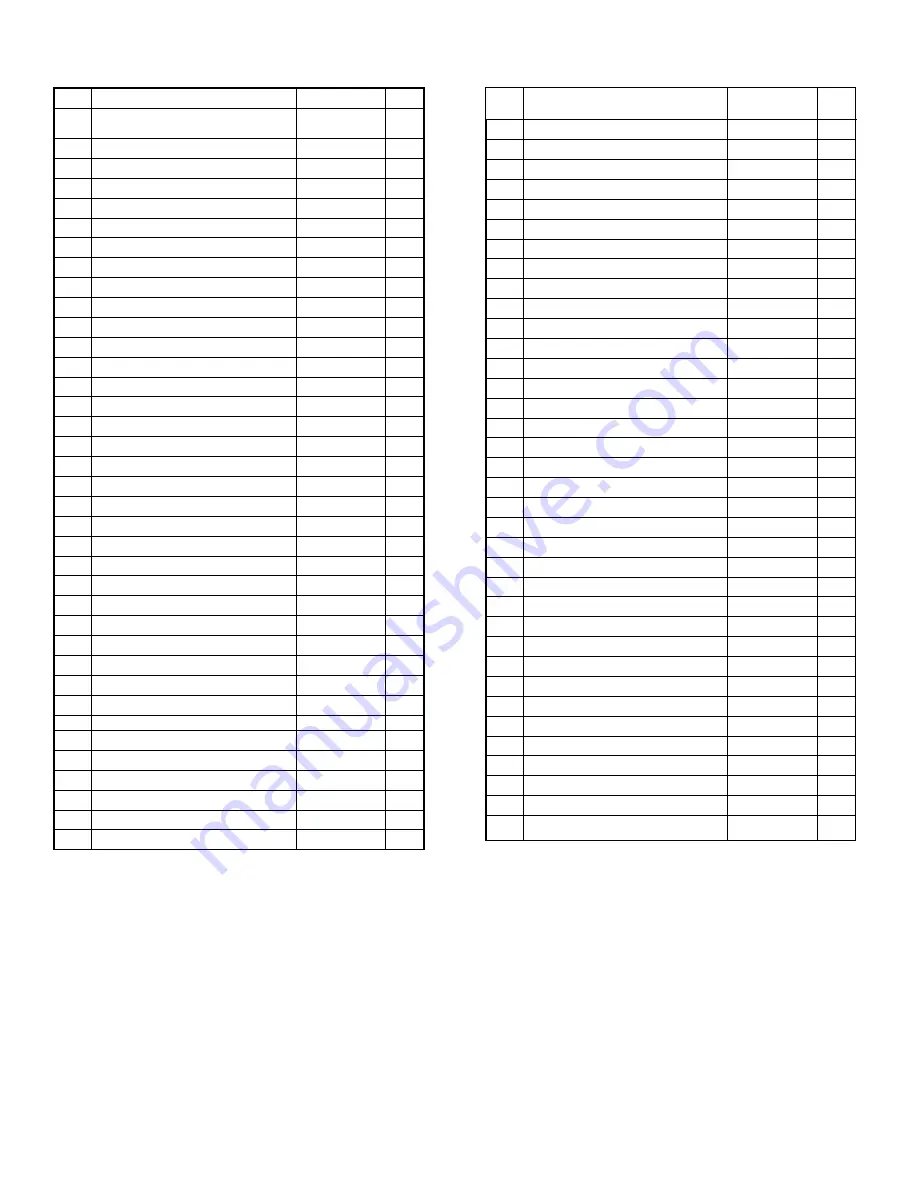

SPARE PARTS SPECIFICATION

№

DENOMINATION

ITEM №

PCS.

1

ELECTRIC DRIVE MOTOR

–

MR90C/2 INCL. CAPACITOR

P2019.401

1

1A CAPACITOR

P2019.402

1

2

SCREW

–

M6X10

P2019.103

4

3

DRIVE MOTOR PLATE

P2019.104

1

4

BOLT

–

M8X20

P2019.105

3

5

PULLEY

–

Ø97

P2019.206

1

6

WASHER

–

Ø6XØ26

P2019.107

1

7

SCREW

–

M6X16

P2019.108

1

8

SCREW

–

M4X20

P2019.109

2

9

CONTACTOR

–

LT1-D

P2019.110

1

10 CONTACTOR PLATE

P2019.111

1

11 SCREW

–

M5X12

P2019.112

2

12 SEPORATER

P2019.213

1

13 BACK HANDLE

P2019.114

1

14 HYDROPLANING PLATE

P2019.115

1

15 SCREW

–

M6X20

P2019.116

14

16 KNEE

–

3/8"

P2019.117

1

17 FILTER

P2019.118

1

18 FILTER MESH

P2019.119

1

19 SEAL

P2019.120

1

20 NIPPLE

P2019.121

1

21 CLAMP

P2019.122

1

22 RUBBER HOSE

P2019.123

1

23 QUICK CONNECTION

P2019.124

1

24 SPHERICAL VALVE

–

3/8"

P2019.125

1

25 NIPPLE

P2019.126

1

26 BOLT

–

M6X30

P2019.127

8

27 NIPPLE

P2019.126

1

28 SEAL

–

10X3

P2019.128

2

29 BOLT

–

M8X20

P2019.129

6

30 SPHERICAL VALVE

–

3/8"

P2019.125

1

31 BLEND

P2019.130

1

32 HINGED WATER SUPPLY

P2019.131

1

33

KNOB “UP

-

DOWN”

P2019.132

1

34 STOP SCREW

–

M5X10

P2019.133

1

35 WASHER

–

Ø8

P2019.134

1

36 SCREW

–

M6X20

P2019.116

2

№

DENOMINATION

ITEM №

PCS.

37 PIN BEARING BLOCK

P2019.135

1

38 PLATE SPRING

P2019.136

2

38A WIDE WASHER

–

Ø8X20

P2019. 134A

1

39 PIN

P2019.137

1

40 RUBBER SEAL

P2019.140

1

41 SPINDLE MOOVING BLOCK

P2019.138

1

42 SCREW

–

M6X20

P2019.116

2

43 SPINDLE HOUSING

P2019.139

1

44 BELT

–

630X20X1.7

P2019.341

1

45 FRONT HANDLE

P2019.142

1

46 WATER PROTECTION

P2019.143

1

47 WATER PROTECTION HOLDER

P2019.144

1

48 COVER

P2019.145

1

49 SCREW

–

M4X8

P2019.146

2

50 SPINDEL COVER

P2019.147

1

51 SPINDEL NUT

P2019.148

1

52 BEARING

–

7206C

P2019.149

2

53 PLATE SPRING

P2019.136

2

54 STOP BUTTON

P2019.150

1

55 START BUTTON

P2019.151

1

56 PROTECTION COVER

P2019.152

1

57 LEFT OUTER BLOCK

P2019.153

1

58 LEFT INNER BLOCK

P2019.154

1

59 LABYRINTH NUT

P2019.155

1

60 LABYRINTH

P2019.156

1

61 SPINDLE

P2019.157

1

62 POWER SUPPLY CORD

P2019.158

1

63 SATELIT

P2019.259

1

64 COVER

P2019.160

1

65 SCREW

–

M4X12 DECORATION P2019.161

7

66 BODY

P2019.262

1

67 RIGHT OUTER BLOCK

P2019.163

1

68 RIGHT INNER BLOCK

P2019.164

1

69 WASHER

–

Ø10

P2019.165

2

70 BOLT

–

M10X30 /50/

P2019.166

2

71 SET OF WRENCHES

P2019.167

1

Summary of Contents for ROCK DOG ROUTER

Page 6: ...5 ...