25

local Authorized Service Centre or WEIBANG’s exclusive national distributor to complete

this work or for details.

ENGINE

Read the Maintenance section of your engine manual.

LUBRICATION

Use only high quality detergent oil, which has an API service classification of SF-SJ. Select the

oil's SAE viscosity grade according to your expected operating temperature.

NOTE:

Although multi-viscosity oils (5W30,10W30 etc.) improve starting in cold weather,

these multi-viscosity oils will result in increased oil consumption when used above 0° C

(32° F). Check your engine oil level more frequently to avoid possible engine damage from

running low on oil. Change the oil after every 25 hours of operation, or at least once a year

if the chipper/shredder is not used for 25 hours in one year. Check the crankcase oil level

before starting the engine and after each five (5) hours of continuous use. Retighten the oil

plug securely each time you check the oil level.

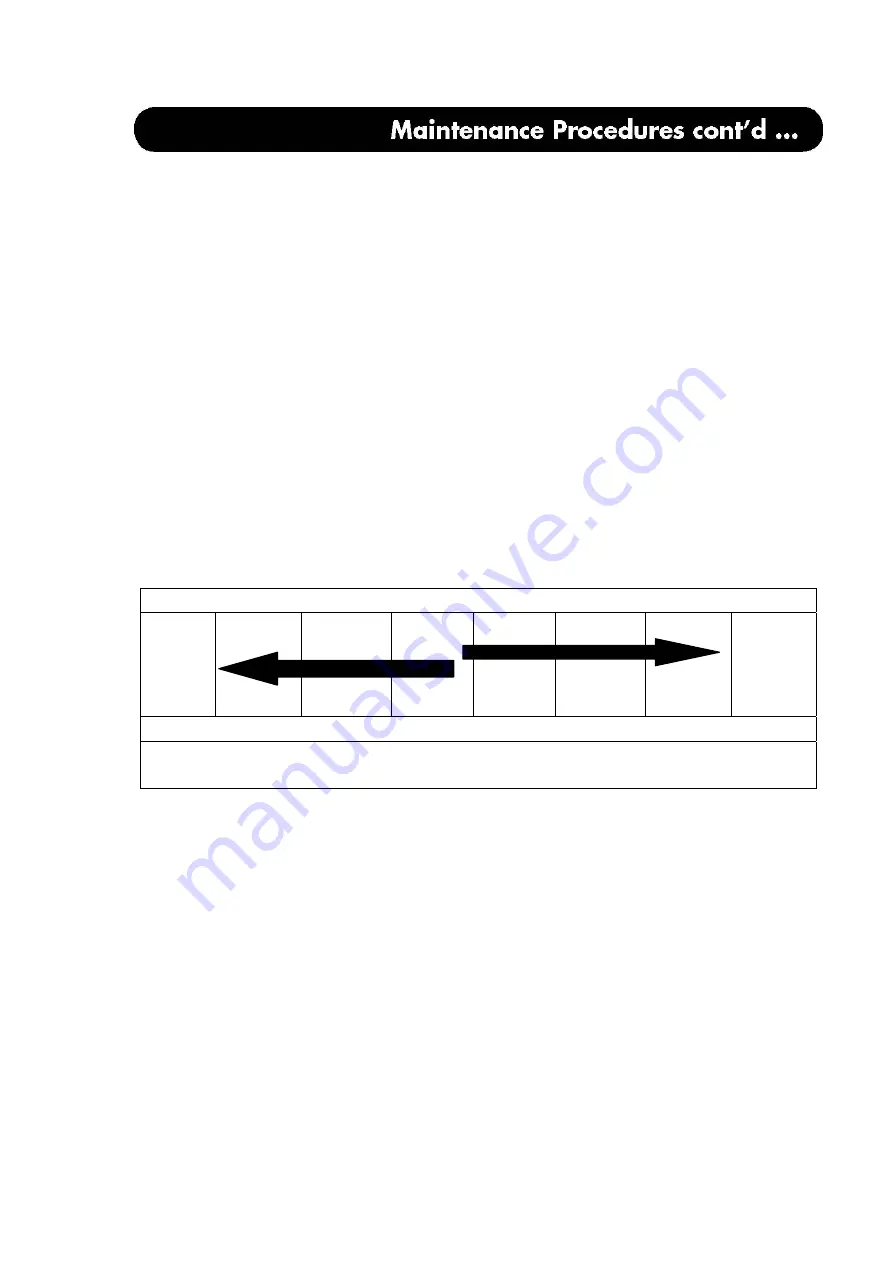

LUBRICATION CHART

SAE VISCOSITY GRADES

CHANGING ENGINE OIL

1. Disconnect sparkplug cable from sparkplug and place the cable where it can not come

into contact with sparkplug.

2. Remove engine oil cap; lay aside on a clean surface.

3. Remove the drain plug on the bottom of the engine and drain oil into a suitable

container. Grasp starter rope handle and pull slowly to rotate the crank shaft and

remove any oil trapped inside of engine.

4. Reassemble and fasten the drain plug. Wipe off any spilled oil from the engine.

5. Refill engine with the recommended lubricant. See "ADD OIL" in the Operation

instructions section of this manual.

6. Reconnect sparkplug cable to sparkplug.

CAUTION: Disconnect sparkplug cable from the sparkplug and place wire where it

cannot come into contact with sparkplug.

LEVEL

5W-30

SAE30

°

F -20

°

0

°

30

°

32

°

40

°

60

°

80

°

100

°

°

C -30

°

-20

°

-10

°

0

°

10

°

20

°

30

°

40

°

Temperature range anticipated before next oil change.